Got some good work done

First was a video I made about how to rekey the center console boxes. I made this last week and got it uploaded onto YouTube on Friday:

If you've rekeyed a house lock before, it's pretty similar. If there's interest, I can write a

HOWTO on this with lots of pictures.

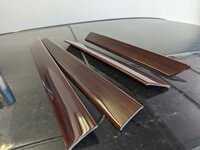

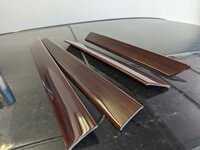

Last week I had also got the remainder of the refinished Zebrano wood. I was only missing the wood panels for each door. I took off the door panels one by one and got these new wood inserts on.

They look amazing!

The new wood all around really freshens up the car

Small update - and yeah, it's a bit silly since this car only has 143hp

I bought the AMG part numbers for the pedals and swapped those out

170-300-00-04 - accelerator

170-290-01-82 - brake pedal

203-430-00-84 - emergency brake

They look great and also have a good grip. My old pedals were disgusting and slippery. The brake pedal and emergency brake pedals are a straight swap. You have to pull the pedal cover off the accelerator and then do some trimming with side cutters until the AMG pedal cover slipped over the W124 pedal nicely. Quick, easy, and rewarding. No more shoes slipping off the pedals!

The last job I took on was replacing the struts/shocks and strut mounts. Shout out to

@Alphasud40 for selling me the parts for a super fair price a while back ($200 for 2x struts, 2x bump stop / dust covers, 2x ball joints and he threw in 2 aftermarket strut mounts). I sold the aftermarket strut mounts included and used that money towards two Mercedes-Benz branded strut mounts (

124-320-14-44-64).

The struts/shocks are both Bilstein B4 (

22-001856) struts and were new in box! This is my first time doing this type of job - so I consulted the FSM (

32-0100). Got the car up on jack stands, took the wheel off.

I bought a cheap spring compressor a while back which looks similar to the MB tool, so I tried to give that a shot. The manual recommends trying to fit 8 coils in-between the plates. The kit is ~$50 on eBay and looks like this:

The smaller plates were the ones to use (bigger ones I think for R129 or W126). However, the plates themselves did not fit very well between the coils (only about 15mm of clearance). I should have taken a picture... I had to use a 4 pound hammer to bash them into place. Once they were in place, I fed the long compressing arm through the bottom. It wasn't even close to being at the correct angle to engage with the slots in the top plate. I

probably could have lined it up if I slid a jack under the control arm and jacked it up so the arm is going through straight... but I didn't feel comfortable continuing.

Springs can kill you  I felt like either I made a mistake or this kit is just garbage; not sure which (but leaning towards kit being trash)

I felt like either I made a mistake or this kit is just garbage; not sure which (but leaning towards kit being trash). Getting the plates out was a bit of a challenge, I had to chisel them out. Packed up the blue briefcase and set that aside.

@geraniumtr if you're still following along - maybe you can share some pics of the tool you have? I'm curious if there would still be a problem getting the plates through the coils (and back out).

With no spring compressor and the car still in the air with the wheel off, I just got a bottle jack and set it under the control arm

. I jacked it up enough to see the control arm start to go up just a hair.

Next, I used a 22mm impact wrench to take off the top nut/washer on top of the strut mount. That came off super easy. I used the impact wrench w/ 19mm to take off the three bolts for the strut/shock. The top one you need to counter hold with a combo wrench. After getting that top bolt out, you can go in the car, turn the wheel all the way left... go outside, remove one of the lower bolts from the strut. Back to the car, turn the wheel all the way right, remove the last lower bolt. Then back in the car to line the wheel up straight.

At this point, you can give the spindle some tapping and it'll fall forward. You can hook it or move it out of the way (just don't let it dangle by the brake line). You can remove the shock at this point. Mine were both in HORRIBLE shape. You can compress them both by hand and it would stay there. Sometimes, it would creep up a few millimeters and then stop. The bump stop was melted to the metal too. Bigtime blown out.

With the shock out, you can easily swap out the strut mount. Three 13mm bolts on top and it'll drop right out. Mine were extremely cracked - very poor shape.

It was a little tricky getting things back together. You need to swap over the plastic piece on the old shock (it has clips for holding the ABS sensor and brake wear sensor). There are two tabs you push down and then slide the piece around until it falls off; then put onto the new shock. You can then put the new bump stop on before guiding it through the strut mount. Once it's peeking through the strut mount, I put a washer/nut on the top and hand threaded it just slightly to hold it in place.

Next, you can push the shock up and then try to slide the spindle back into the top notch on the strut. It can take some strength and coordination to get that in place! If you can get the spindle piece back into the notch but the bolt holes don't exactly line up, you can slide a wrench under the shock and use it like a lever to move the shock around until you can feed the long top bolt through. I secured that top bolt in place, counter holding the nut with a combo wrench and zipping together with an impact wrench. I feel a bit bad for ignoring the torque spec, but I did verify it was impossible for me to tighten up by hand (aka gutentight!).

Once that's locked in, you can get the two lower bolts/washers that sit up against the spindle. For the lower portion, the strut itself has a hole to let a positioning notch (on the spindle) go through - super important to have that locked in before you tighten those two remaining bolts. I did those by hand first - then got in car, turned steering wheel again, used impact to secure, repeat. I used the gutentight torque spec for these too

With that connected again, I released the pressure on the bottle jack and set it aside, and put the wheel back on.

Once the car was back on the ground, I got the 22mm nut/washer on top of the strut secured and took it for a spin (speeding up over some speedbumps).

Wow, what an improvement! There are still problems with the steering linkage (those are coming up soon) and my ball joints are blown out... but it feels great when going over bumps or doing a sharp turn.

That's about it for this weekend... Up next, I think it'll be some final steering components and then alignment. Going to try and get these done before the end of the year:

- 2x ball joints

- steering drag link

- steering damper

- 2x tie rods

- idler arm bushing kit

- alignment

I did all of that front end work on my long gone 86-300E back in the 90s when I installed Eibach lowering springs and Koni Red adjustable shocks. In fact I did the shocks twice. I spent a lot of time under that car. Eibach assured me the MB shocks would work great with their springs so I purchased 4 brand new stock MB Shocks from Mercedes. The car road like a “Buckboard” so I changed the fronts again to the Koni Adjustable Reds and sold the brand new MB shocks for 1/2 price $75.00. That was a real bummer.

I did all of that front end work on my long gone 86-300E back in the 90s when I installed Eibach lowering springs and Koni Red adjustable shocks. In fact I did the shocks twice. I spent a lot of time under that car. Eibach assured me the MB shocks would work great with their springs so I purchased 4 brand new stock MB Shocks from Mercedes. The car road like a “Buckboard” so I changed the fronts again to the Koni Adjustable Reds and sold the brand new MB shocks for 1/2 price $75.00. That was a real bummer.