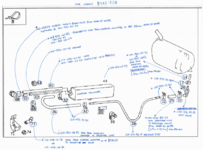

Does anyone have a picture of the car with the charcoal cannister exposed? I'd like to see what is replaceable / should be replaced once the fender is off. I have the EPC open now and am shopping.

BTW @gsxr - EPC master - which part do I order for part #80? Is it 117-078-04-81 or 000-987-27-27? Thanks.

BTW @gsxr - EPC master - which part do I order for part #80? Is it 117-078-04-81 or 000-987-27-27? Thanks.

Last edited:

![[500Eboard] 7616BB51-04A9-4B60-8D71-B4545FB58B05.jpeg [500Eboard] 7616BB51-04A9-4B60-8D71-B4545FB58B05.jpeg](https://www.500eboard.co/forums/data/attachments/127/127623-1e042d2e00e3623609376819b9c6af08.jpg?hash=HgQtLgDjYj)