Upgrading the stock 110Amp alternator with a 150Amp alternator from a 2001 ML55 provides an additional 40 amperes worth of potential current supply for the 500E electrical system’s consumption.

Background:

I’ve finally gotten around to replacing my stock 110Amp Bosch alternator with the 150Amp Bosch version from a 2001 ML55.

My used ML55 150A alternator bench-tested OK, but I also wanted to verify the condition of its voltage regulator brushes prior to any installation.

The 150A VR brushes still had decent life left but I opted to start fresh with a new OE replacement VR (Bosch 1 197 311 213) because I’m treating this upgrade as a “one & done” type of project that I don’t plan on revisiting. I’ll replace the 110A alternator's VR with the former 150A VR. The 110A VR will be trashed because its brushes are worn. Afterward, I’ll keep the 110A alternator in storage as a backup.

Poly v-belt removal is a prerequisite of alternator replacement, so I’m also using this opportunity to replace the 6 rib poly v-belt. The current v-belt is over 7 years old & upon closer scrutiny displays fine-checking throughout. I’ll keep this old belt in the car tool bag for a while as an emergency backup.

The Bottom Line: Consider replacing the voltage regulator prior to, & replacing the poly v-belt after alternator installation.

Alternator replacement also provides the opportunity to inspect the condition of many other important collateral items such as the lower wiring harness, transmission & SLS tubing/hoses, oil level sensor, oil pressure sensor, fluid leak sources, etc. I am taking advantage of this opportunity.

Part Numbers:

110A alternator: Bosch 0 123 545 004 (009 154 19 02)

150A alternator: Bosch 0 123 520 012 (010 154 83 02)

Compatibility:

The 150A alternator is a direct fit into the existing 500E alternator brackets.

Both alternators use the same Bosch 1 197 311 213 voltage regulator (p/n 002 154 85 06). The voltage regulator should be inspected/replaced prior to the installation of any used Bosch alternator.

Both alternators are classified by the FSM as “compact” type & are nearly dimensionally identical, with only a few slight & non-critical differences.

To maintain the originally intended rotational characteristics of the 500E’s belt drive system, I replaced the 150A pulley with the 110A pulley.

Reference:

FSM 15-5760-B Removing and Installing Regulator (see HOW-TO)

FSM 15-5700 Removing and Installing Poly V-belt Pulley

Tools:

Bench Vice or flat stable work surface

Pneumatic Impact Wrench

22mm Impact Socket

Pipe Strap Wrench

Large Channel Lock Pliers

Torque Wrench

Old Poly V-belt

The FSM specifies, “Use serrated bit (10mm) with reversing ratchet for holding the shaft”. I improvised an alternative method to perform this task, because, although I have the serrated bit (aka T50 torx bit) to hold the shaft, I didn’t have the required pass-thru socket tool to hold the shaft while simultaneously removing the pulley nut surrounding it. I used common shop tools & items on hand in the garage.

Procedure:

Pulley Nut Removal:

Pulley Nut Installation:

The Pneumatic Impact Wrench torque is stronger than the frictional resistance of the pipe strap wrench. Stop applying the Pneumatic Impact Wrench when the pulley eventually starts rotating within the pipe strap.

The alternator is now ready for installation. Install the alternator into the car using this additional HOW-TO.

Background:

I’ve finally gotten around to replacing my stock 110Amp Bosch alternator with the 150Amp Bosch version from a 2001 ML55.

My used ML55 150A alternator bench-tested OK, but I also wanted to verify the condition of its voltage regulator brushes prior to any installation.

The 150A VR brushes still had decent life left but I opted to start fresh with a new OE replacement VR (Bosch 1 197 311 213) because I’m treating this upgrade as a “one & done” type of project that I don’t plan on revisiting. I’ll replace the 110A alternator's VR with the former 150A VR. The 110A VR will be trashed because its brushes are worn. Afterward, I’ll keep the 110A alternator in storage as a backup.

Poly v-belt removal is a prerequisite of alternator replacement, so I’m also using this opportunity to replace the 6 rib poly v-belt. The current v-belt is over 7 years old & upon closer scrutiny displays fine-checking throughout. I’ll keep this old belt in the car tool bag for a while as an emergency backup.

The Bottom Line: Consider replacing the voltage regulator prior to, & replacing the poly v-belt after alternator installation.

Alternator replacement also provides the opportunity to inspect the condition of many other important collateral items such as the lower wiring harness, transmission & SLS tubing/hoses, oil level sensor, oil pressure sensor, fluid leak sources, etc. I am taking advantage of this opportunity.

Part Numbers:

110A alternator: Bosch 0 123 545 004 (009 154 19 02)

150A alternator: Bosch 0 123 520 012 (010 154 83 02)

Compatibility:

The 150A alternator is a direct fit into the existing 500E alternator brackets.

Both alternators use the same Bosch 1 197 311 213 voltage regulator (p/n 002 154 85 06). The voltage regulator should be inspected/replaced prior to the installation of any used Bosch alternator.

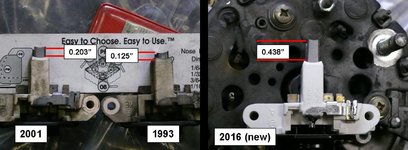

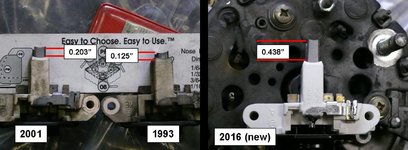

Both alternators are classified by the FSM as “compact” type & are nearly dimensionally identical, with only a few slight & non-critical differences.

- Length: 150A is 3/16” (4.75mm) longer on the voltage regulator end.

- Terminal Location: When mounted in bracket, the 150A configuration provides better service access to D+ terminal than the 110A. B+ terminal locations are the same.

- Pulley Diameter:

- 150A: 55mm nominal OD (50mm groove OD).

- 110A: 49mm nominal OD (44mm groove OD).

- Pulley nut size for both: 22mm hex

To maintain the originally intended rotational characteristics of the 500E’s belt drive system, I replaced the 150A pulley with the 110A pulley.

Reference:

FSM 15-5760-B Removing and Installing Regulator (see HOW-TO)

FSM 15-5700 Removing and Installing Poly V-belt Pulley

Tools:

Bench Vice or flat stable work surface

Pneumatic Impact Wrench

22mm Impact Socket

Pipe Strap Wrench

Large Channel Lock Pliers

Torque Wrench

Old Poly V-belt

The FSM specifies, “Use serrated bit (10mm) with reversing ratchet for holding the shaft”. I improvised an alternative method to perform this task, because, although I have the serrated bit (aka T50 torx bit) to hold the shaft, I didn’t have the required pass-thru socket tool to hold the shaft while simultaneously removing the pulley nut surrounding it. I used common shop tools & items on hand in the garage.

Procedure:

Pulley Nut Removal:

- Mount the alternator horizontally in a bench vise or on a stable flat surface.

- Use the Pneumatic Impact Wrench fitted with the 22mm (7/8”) Impact Socket to remove the pulley nut (the nut comes off easily without the need of a pipe strap wrench to hold the pulley).

- Pull the pulley straight off the shaft (should come off by hand).

Pulley Nut Installation:

- Squarely seat the replacement pulley on shaft by hand.

- Finger-tighten the nut onto the shaft

- Tighten the pipe strap wrench around the pulley in the counter-direction of nut installation (have the strap wrench handle rest against a solid surface).

- Use the Pneumatic Impact Wrench to further tighten (but not over-torque) the nut onto the shaft using 2 – 3 short bursts (similar technique as lug nuts onto wheel rims).

The Pneumatic Impact Wrench torque is stronger than the frictional resistance of the pipe strap wrench. Stop applying the Pneumatic Impact Wrench when the pulley eventually starts rotating within the pipe strap.

- Remove the pipe strap wrench, and then protect the pulley grooves with old poly v-belt or similar material.

- Carefully fit the jaws of a large set of Channel Lock Pliers around the old belt material in the counter-direction of nut rotation & hold handles down against a solid surface (the material protects the pulley grooves from the Pliers jaws).

- Fit the 22mm Socket onto the Torque Wrench & incrementally final torque the nut to 80 Nm (60ft lb).

The alternator is now ready for installation. Install the alternator into the car using this additional HOW-TO.