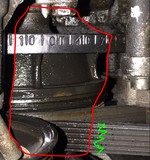

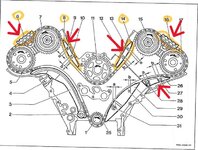

hi friends, my w210 M119 is malfunctioning as already reported here on the forum, you recommended me to remove the valve cover to see if the timing chain is on time, analyzing the crank pulley I realized that it seems to be out of time, I will attach a photo for everyone's opinion.

if the crank pulley is out of time, has the timing chain skipped a tooth?

if the crank pulley is out of time, has the timing chain skipped a tooth?