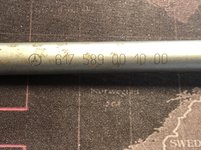

I just ordered a reman Bosch alternator from FCP Euro (which came in record time BTW), and the WIS says to use a 10mm socket with "internal serrations together with reversing ratchet to hold the shaft." The Torx T-50 seems to have some play in it. Before I go ahead and strip it, is this the right tool for the job? I'm a bit puzzled by the WIS reference to a 10mm socket with internal serrations. Maybe there are metric Torx tools as well?

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

Alternator Pulley Removal

- Thread starter emerydc8

- Start date