Hi Everyone,

I believe I have a sort of "odd" issue among the M119 ignition system. I've done a lot of looking through the forum and cannot find anything that is similar to what I am experiencing for both the 400's and 500's... Since the colder weather in Maryland has started (and even since we were in the 60 degree range a month or so ago) my 1992 400E has occasionally had this odd idle after running for a minute or two. The car will have a sudden noticeable drop in RPM followed by a pretty rough misfire that, as far as I've experienced, does not go away after driving for a few minutes. I have tried to drive through the misfire after leaving a few local stores (engine has likely been running for about a 5 or 10 minute drive, not enough to really warm everything up) to no avail. When I turn the car off and restart it, it will run perfectly again immediately after the restart, with no misfire or rough idle, when roughly 30 seconds to a minute after idling the issue will resume. The rough idle does not occur every time I drive, but i've found if I start the car, and continue driving at above idle speeds, i.e on the highway or backroads, the car will continue to run well without any issues. If it's not up to temp and I have to stop at a stop sign, stop light or leave it running in the driveway to warm up, it will sometimes start idling poorly and be low on power. Also, during this misfire, the car is very slow to rev and with it being pretty cold out now, the car appears to output more condensation and exhaust from the tailpipe compared to when it is running properly.

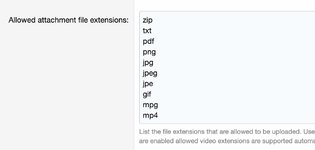

I have attached a link for a video file on dropbox showing the audible drop in RPM (initial RPM drop around 6 seconds into the video and the big RPM drop around 8 seconds into the video with additional engine noise shown towards the end of the video). I would just attach the video, but it is giving some kind of error for the video file not being of the file type expected, even with it being a .mp4 file. The misfire starts about 15 to 20 seconds after starting the 400 for the 2nd time tonight, followed by what appears to sound similar to a valve/lifter tap or completely missing a cylinder or two. Hard to tell due to the increased noise and lack of power. All of this occurred while just trying to run the car after being away and not running the car for about 2 or 3 weeks.

During the initial startup, after about 2 to 3 minutes of normal idling, the rough idle occurred, then I killed the car and restarted it and began the recording linked below. I cropped about 10 to 15 seconds of normal idling out the video for time and file size purposes, but it is unlike any other ignition issue that I have messed with! It is worth noting that the previous owner replaced almost all ignition components, including the distributor caps, rotors, plugs, wires, ignition coil, fuel pumps and fuel filter within the past 2 years in his ownership. All parts were replaced with OE/OEM parts with the exception of a Napa brand fuel filter. I also rebuilt the wiring harness within a few days of my ownership due to an charging issue, rough idle, lack of power/stall issue and a christmas tree of all instrument cluster lights staying illuminated while the car was running (yes, literally all), which was all related to the lower harness being fully stripped of its insulation, I guess it was the original harness. The car has roughly 124k miles on it (if that matters).

Thanks in advance for any help!

Owen

Dropbox link: 20201222_232640_1.mp4 - P.S. you are probably going to want to turn the volume up to really hear the misfire issue properly in the video!

I believe I have a sort of "odd" issue among the M119 ignition system. I've done a lot of looking through the forum and cannot find anything that is similar to what I am experiencing for both the 400's and 500's... Since the colder weather in Maryland has started (and even since we were in the 60 degree range a month or so ago) my 1992 400E has occasionally had this odd idle after running for a minute or two. The car will have a sudden noticeable drop in RPM followed by a pretty rough misfire that, as far as I've experienced, does not go away after driving for a few minutes. I have tried to drive through the misfire after leaving a few local stores (engine has likely been running for about a 5 or 10 minute drive, not enough to really warm everything up) to no avail. When I turn the car off and restart it, it will run perfectly again immediately after the restart, with no misfire or rough idle, when roughly 30 seconds to a minute after idling the issue will resume. The rough idle does not occur every time I drive, but i've found if I start the car, and continue driving at above idle speeds, i.e on the highway or backroads, the car will continue to run well without any issues. If it's not up to temp and I have to stop at a stop sign, stop light or leave it running in the driveway to warm up, it will sometimes start idling poorly and be low on power. Also, during this misfire, the car is very slow to rev and with it being pretty cold out now, the car appears to output more condensation and exhaust from the tailpipe compared to when it is running properly.

I have attached a link for a video file on dropbox showing the audible drop in RPM (initial RPM drop around 6 seconds into the video and the big RPM drop around 8 seconds into the video with additional engine noise shown towards the end of the video). I would just attach the video, but it is giving some kind of error for the video file not being of the file type expected, even with it being a .mp4 file. The misfire starts about 15 to 20 seconds after starting the 400 for the 2nd time tonight, followed by what appears to sound similar to a valve/lifter tap or completely missing a cylinder or two. Hard to tell due to the increased noise and lack of power. All of this occurred while just trying to run the car after being away and not running the car for about 2 or 3 weeks.

During the initial startup, after about 2 to 3 minutes of normal idling, the rough idle occurred, then I killed the car and restarted it and began the recording linked below. I cropped about 10 to 15 seconds of normal idling out the video for time and file size purposes, but it is unlike any other ignition issue that I have messed with! It is worth noting that the previous owner replaced almost all ignition components, including the distributor caps, rotors, plugs, wires, ignition coil, fuel pumps and fuel filter within the past 2 years in his ownership. All parts were replaced with OE/OEM parts with the exception of a Napa brand fuel filter. I also rebuilt the wiring harness within a few days of my ownership due to an charging issue, rough idle, lack of power/stall issue and a christmas tree of all instrument cluster lights staying illuminated while the car was running (yes, literally all), which was all related to the lower harness being fully stripped of its insulation, I guess it was the original harness. The car has roughly 124k miles on it (if that matters).

Thanks in advance for any help!

Owen

Dropbox link: 20201222_232640_1.mp4 - P.S. you are probably going to want to turn the volume up to really hear the misfire issue properly in the video!