A delivery of new parts arrived today, allowing me to officially complete the cam oiler tube replacement job. The car now has:

I installed the new oil separator with breather tube in the right cylinder head. I stand corrected regarding my previous statement of the old breather tube being salvageable. The new tube is like rubber. It is pliable. It bends & can be squeezed. The old tube was solid like Bakelite. I thanked it for its service, then decommissioned it into the dustbin.

Surprisingly, the right cam cover went on rather quickly & easily compared to how it came off & compared to the left side. I double-checked because I couldn’t believe it. Its infamous lower rear cover bolt (with new crush washer) also went on rather easily.

I believe some of the previous gasket leaking was attributed to the difficulty previous hands may have had in trying to correctly torque the two infamous lower rear cover bolts from Hell. Proper tools on hand excommunicated most of their devilishness this time.

Other jobs officially completed today:

- Aluminum cam oiler tubes with new orings

- new upper timing chain retainers

- new oil separator & breather tube

- new cover gaskets

- new cover bolt washers

I installed the new oil separator with breather tube in the right cylinder head. I stand corrected regarding my previous statement of the old breather tube being salvageable. The new tube is like rubber. It is pliable. It bends & can be squeezed. The old tube was solid like Bakelite. I thanked it for its service, then decommissioned it into the dustbin.

Surprisingly, the right cam cover went on rather quickly & easily compared to how it came off & compared to the left side. I double-checked because I couldn’t believe it. Its infamous lower rear cover bolt (with new crush washer) also went on rather easily.

I believe some of the previous gasket leaking was attributed to the difficulty previous hands may have had in trying to correctly torque the two infamous lower rear cover bolts from Hell. Proper tools on hand excommunicated most of their devilishness this time.

Other jobs officially completed today:

- new spark plugs

- new distributor caps & rotors

- new protective wiring loom replacement

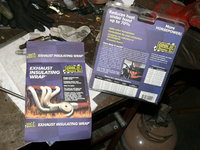

Operation Leak Elimination. Good ol' permatex is gonna be going places..

Operation Leak Elimination. Good ol' permatex is gonna be going places..