I figured it could be useful for all W124 owners as the design is similar.

If you take your wheel off, you should see a bunch of nuts screwed in all around the wheel arch. This holds the fender liner, if you take those off, you will see there are screws that come from the structure of the car. If your W124 has seen a lot of miles, I highly recommend checking this area. The nuts can get loose, the screws can rust, and a lot of organic garbage can accumulate in there which can lead to more rust.

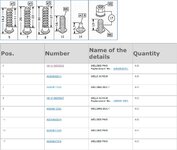

If you have misplaced your nuts holding your liner, this is the part number: 201-990-00-50

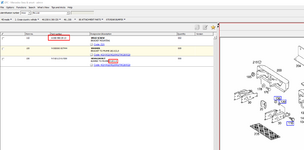

Here is one of mine up close:

With that said, I've taken my liner and fenders off on my 300TE and found that one of the screw is completely broken!

So, I'm curious if anyone knows of any solutions or has dealt with this before. Replacing these screws could be very important preventative maintanence, especially on higher mileage vehicles.

If you take your wheel off, you should see a bunch of nuts screwed in all around the wheel arch. This holds the fender liner, if you take those off, you will see there are screws that come from the structure of the car. If your W124 has seen a lot of miles, I highly recommend checking this area. The nuts can get loose, the screws can rust, and a lot of organic garbage can accumulate in there which can lead to more rust.

If you have misplaced your nuts holding your liner, this is the part number: 201-990-00-50

Here is one of mine up close:

With that said, I've taken my liner and fenders off on my 300TE and found that one of the screw is completely broken!

- You can't reach the other side of the screw. It seems to be between the arch and the engine frame.

- I don't believe it was welded in. My guess is a riv nut or captive stud.

So, I'm curious if anyone knows of any solutions or has dealt with this before. Replacing these screws could be very important preventative maintanence, especially on higher mileage vehicles.