I just finished rebuilding my cv axles for my 300D and figured id make a DIY write up and parts list:

1. Cut the old boots off (there is a metal ring inside the smallest crease do not cut it)

2. Scoop all the old grease you can out and give them a preliminary wash with solvent to make them cleaner to work with.

3. Take a screw driver or something similar and pry the end cap off of the CV joint on the side that attaches to the differential.

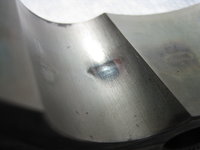

4. Clean away the grease and push the cup all the way in to expose the circlip that holds the CV joint onto the axle and remove it.

5. Pull the CV off the axle splines (I pushed the cup all the way in and pulled out and it came right off).

6. Thoroughly clean all the old grease out of the CV joints with solvent. (I did not disassemble the CV joint itself but just used brushes and solvent and moved it around to get everything out.) I didn't take the end of the CV shaft that goes to the wheel off but just soaked and scrubbed it.

7. Put new boot on, don't forget to put the little ring in the new boot (I had to seat one side of it and then use a screw driver to pry it into its crease where it sits). Everything goes on from the differential side of the CV shaft (you will have to use something such as a screw driver in my case to stretch the small end of the boot over the splines on the end of the CV shaft because they are slightly larger than the rest of the shaft).

8. Grease the joint (I used about 5 two finger scoops of grease per joint or roughly 4oz).

9. Make sure the boot is clean and the CV cup is clean where the clamp goes otherwise the boot will be able to rotate even after clamping it down. Put the clamps on (the large clamp went on easier than the small clamp, it came pre-bent and I just put it on the first two teeth and crimped the ear of the clamp. But the smaller clamp came un-bent and was a pain to bend evenly because if you didn't, it wouldn't be long enough to seat on its two only teeth. I ended up bending it around the shaft and using a hammer and screw driver to flatten any sharp bends that weren't laying smooth. Then stuck a tiny screw driver in the clamp and used the teeth to pry it on and then crimped the ear).

10. Put your 2nd boot on the shaft and then put the CV joint for the differential side on and replace the circlip.

11. Put RTV on the inside of the CV cap on the differential side and hammer it back on.

12. Repeat steps 7-9 on the differential side of the CV axle.

Parts List:

These are what I used, I can't guarantee that all axles use the same boots etc. But in my case these are the parts for axles from a 210mm 2.65 differential.

(4) Axle Boot: 124-357-01-91 $125.80 (For 4)

(4) Small Clamp (35mm): 124-997-34-90 $7.12 (For 4)

(4) Large Clamp (76mm): 124-997-30-90 $7.40 (For 4)

(2) 14 OZ containers of CV grease $30 (For 2)

$140.32 from MB OEM Parts

Total: $170.20

A lot better than $1,800 for 2 new axles from Mercedes.

1. Cut the old boots off (there is a metal ring inside the smallest crease do not cut it)

2. Scoop all the old grease you can out and give them a preliminary wash with solvent to make them cleaner to work with.

3. Take a screw driver or something similar and pry the end cap off of the CV joint on the side that attaches to the differential.

4. Clean away the grease and push the cup all the way in to expose the circlip that holds the CV joint onto the axle and remove it.

5. Pull the CV off the axle splines (I pushed the cup all the way in and pulled out and it came right off).

6. Thoroughly clean all the old grease out of the CV joints with solvent. (I did not disassemble the CV joint itself but just used brushes and solvent and moved it around to get everything out.) I didn't take the end of the CV shaft that goes to the wheel off but just soaked and scrubbed it.

7. Put new boot on, don't forget to put the little ring in the new boot (I had to seat one side of it and then use a screw driver to pry it into its crease where it sits). Everything goes on from the differential side of the CV shaft (you will have to use something such as a screw driver in my case to stretch the small end of the boot over the splines on the end of the CV shaft because they are slightly larger than the rest of the shaft).

8. Grease the joint (I used about 5 two finger scoops of grease per joint or roughly 4oz).

9. Make sure the boot is clean and the CV cup is clean where the clamp goes otherwise the boot will be able to rotate even after clamping it down. Put the clamps on (the large clamp went on easier than the small clamp, it came pre-bent and I just put it on the first two teeth and crimped the ear of the clamp. But the smaller clamp came un-bent and was a pain to bend evenly because if you didn't, it wouldn't be long enough to seat on its two only teeth. I ended up bending it around the shaft and using a hammer and screw driver to flatten any sharp bends that weren't laying smooth. Then stuck a tiny screw driver in the clamp and used the teeth to pry it on and then crimped the ear).

10. Put your 2nd boot on the shaft and then put the CV joint for the differential side on and replace the circlip.

11. Put RTV on the inside of the CV cap on the differential side and hammer it back on.

12. Repeat steps 7-9 on the differential side of the CV axle.

Parts List:

These are what I used, I can't guarantee that all axles use the same boots etc. But in my case these are the parts for axles from a 210mm 2.65 differential.

(4) Axle Boot: 124-357-01-91 $125.80 (For 4)

(4) Small Clamp (35mm): 124-997-34-90 $7.12 (For 4)

(4) Large Clamp (76mm): 124-997-30-90 $7.40 (For 4)

(2) 14 OZ containers of CV grease $30 (For 2)

$140.32 from MB OEM Parts

Total: $170.20

A lot better than $1,800 for 2 new axles from Mercedes.

Attachments

-

CV 10.jpg2.9 MB · Views: 90

CV 10.jpg2.9 MB · Views: 90 -

CV 3.jpg227.9 KB · Views: 80

CV 3.jpg227.9 KB · Views: 80 -

CV 2.jpg288.1 KB · Views: 77

CV 2.jpg288.1 KB · Views: 77 -

CV 1.jpg225.2 KB · Views: 74

CV 1.jpg225.2 KB · Views: 74 -

CV 7.jpg2.6 MB · Views: 78

CV 7.jpg2.6 MB · Views: 78 -

CV 9.jpg3.1 MB · Views: 82

CV 9.jpg3.1 MB · Views: 82 -

CV 11.jpg220.4 KB · Views: 78

CV 11.jpg220.4 KB · Views: 78 -

CV 8.jpg2.3 MB · Views: 78

CV 8.jpg2.3 MB · Views: 78 -

CV 5.jpg1.7 MB · Views: 79

CV 5.jpg1.7 MB · Views: 79 -

CV 6.jpg2.5 MB · Views: 85

CV 6.jpg2.5 MB · Views: 85 -

CV 4.jpg3 MB · Views: 90

CV 4.jpg3 MB · Views: 90