Hi guys,

Im building a group C race car from scratch, it has a twin turbo M119.960 block and im doing everything Mercedes did to the original engine in the Sauber C9 but with newer components, I have an M119.960 block with its turbos happily bolted on with new exhaust, new ITB inlet, new fuel system, new wiring loom, new ECU, new oil system, new FEAD, dry sumped and its getting a 6sp manual gearbox, happy to post pictures of what ive done if anybody is interested,

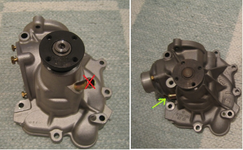

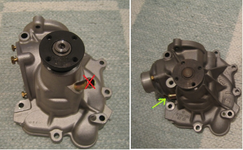

I have bolted a new water pump on as the original was a bit gunky, I have all the connections sorted but there appears to be 1 port I cant identify, using this forum it seems to be a drain port according to this thread, post #25, image #2

if I start the engine will water come out? - does it need to be capped off? if its a drain port I could plumb this into the system and have a tap somewhere?

Im not planning on starting the engine soon but im just doing the engine plumbing so wanted to check what it was incase I need to include this in work over the coming days

Im building a group C race car from scratch, it has a twin turbo M119.960 block and im doing everything Mercedes did to the original engine in the Sauber C9 but with newer components, I have an M119.960 block with its turbos happily bolted on with new exhaust, new ITB inlet, new fuel system, new wiring loom, new ECU, new oil system, new FEAD, dry sumped and its getting a 6sp manual gearbox, happy to post pictures of what ive done if anybody is interested,

I have bolted a new water pump on as the original was a bit gunky, I have all the connections sorted but there appears to be 1 port I cant identify, using this forum it seems to be a drain port according to this thread, post #25, image #2

M119 water pump upgrade? | M119 Engine

Guys, I thought Dave said there was some long thread about using a M120 water pump on our cars? Anyone here have the information , parts required and experience here? Michael

www.500eboard.co

if I start the engine will water come out? - does it need to be capped off? if its a drain port I could plumb this into the system and have a tap somewhere?

Im not planning on starting the engine soon but im just doing the engine plumbing so wanted to check what it was incase I need to include this in work over the coming days