Anderzen, I don’t deal with people on Instagram or social media in general aside from initial enquiries. Main reason is it becomes difficult to follow, but also partly because I rarely go on there. So far, you’ve asked for various discounts in exchange for influencer style social media coverage. As explained, we don’t do this. If you see our parts on a car, the customer has chosen and bought them.

We didn’t respond about you being so proud of those top mounts because in our opinion they are dangerous and shouldn’t be on the market. If you’re happy testing parts like that from one size fits all sellers who lack engineering experience - on what for us is a $20k car, you’re a braver man then me.

I’ve bought parts from “kangaroos team”. The machining work was awful, the material looked like it was stored in a pond, it didn’t fit at all and I was told that apparently a tolerance of 1mm on bolt holes is to be expected, that’s tough shit and I should elongate. If you look closely at some of the details on the builds, they are not designs which would go through scrutineering in this country and I certainly would not want to share a track with them whatsoever. I’ve seen multiple complaints also, about the manifolds splitting, clutches not fitting and I can assure you the design and engineering is visibly sub par and sometimes obviously flawed on a lot of their components. Any trained eye can see this.

But people like cheap hey?

One concern is no mention of balancing details on the flywheels. Dynamic balancers are expensive machines, especially if you want to hold a good tolerance. Have they got one in house? Or do we just not talk about that and blindly recommend someone lacking in engineering experience putting out cheap parts because they’re fast? I do hope people don’t start to get engine issues.

We could easily sell a cheap kit for auto ring gears with off the shelf cover and lie about the torque rating, but as it stands a 240mm cerametallic on a stiff spring is one of the worst clutch experiences I’ve ever had. So we don’t sell those to people. If you want a race clutch, you get a race clutch to suit what you’re doing, not a road clutch bodged to hold more torque. If you want a dual purpose or high torque system for a road car, that is what you get. Something that doesn’t make you look forward to getting out of the car. Every order, we ask about the car, torque level, where and how it will be used to decide on what to offer.

The lead time is because every component is designed, machined, assembled and tested in the UK by multiple people earning a good wage. You asked for a high torque road 900NM road clutch. The cover quoted was for a twin 228mm race cover in billet alloy, modified with a curly tipped diaphragm to suit the OEM release bearing and extra springs to ensure a full release on the road. The cover, inter plates and flywheel need machining from scratch because a twin 228mm isn’t a usual choice and the setup height is specific to that kit. The Kevlar discs need bonding, setting and the flywheel needs every starter motor and timing tooth machined into the billet, this is then dynamically balanced. This isn’t something knocked out in a shed on the old bloc or imported from China in a few days.

If you can’t see or appreciate the differences or our attention to detail when making comparisons, there isn’t much we can do.

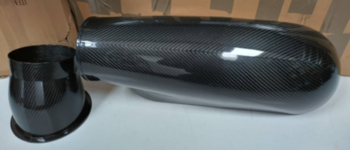

Here are the 500 and 1200NM twin plate kits that drives like a normal clutch on the road. Response is improved along with thermal capacity.

View attachment 179861

This is a kit for the 190e, designed to improve inertia whilst still driving well on the road.

View attachment 179862

rennsportfactory.co.uk

rennsportfactory.co.uk

facebook.com

facebook.com

facebook.com

facebook.com