Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What’s your best buy DIY garage tools?

- Thread starter JC220

- Start date

I'll make multiple runs with mine when cleaning all the droppings from the pine trees. Those things seem to always be dropping something on the ground...

When I moved into this home in 1978 there was a 40’ pine tree in a planter next to the driveway and about 20’ from the garage door. It was a magnificent looking tree as far as trees go. Sure it dropped pine needles that had to be cleaned up weekly but not to much of a problem UNTIL about a year later when we had a freek thunderstorm! When I went out the front door after the storm passed I was shocked to see about 1/2 of my yard and part of my roof completely brown covered in pine needles about an inch deep. That was enough and the demise of the tree

I spent the following week cutting down the mess making tree. I actually climbed up as high as I could and tied a rope even higher. With my 10 year old son pulling on the rope from far away I topped about 20’ with it falling towards the street. I was very nervous about the the bottom of the cut slipping back and knocking me out of the tree. Anyway, after that it took the rest of the week to cut it down to the stump. Since my yard is practically beach sand I dug out the stump down about 4’ I cut it off with a chainsaw.

I finally cut it up into fire wood and stacked it behind my toolshed. About a year later we had our first and last wood fire in the fireplace. It was a PITA to clean out the ashes. So I took the rest of the firewood out to a construction site I was working on and dumped it. Glad to see it gone. Others picked it up and took it home.

Anyway, that was my first and last one tree.

I’m not a “tree hugger”

lol

Our Flagstaff house is in one of the largest contiguous Ponderosa pine forests in North America. I couldn't tell you how many trees we have on the 1/2 acre property, suffice to say it's easily 20-30. They're all 40'-60' tall, if not taller, and constantly drop/drip stuff. If it's not needles (primarily in the spring) it's pieces of lower branches, which die off naturally and then rot and fall to the ground. They also drip pine sap constantly, although the rate changes with the season. Right now it's small, fine droplets, where in the spring as they're producing "offspring" it's heavier. You definitely don't want to park your car outside unless it's covered. And they also drop pine cones and the little pods from when they produce pollen.When I moved into this home in 1978 there was a 40’ pine tree in a planter next to the driveway and about 20’ from the garage door. It was a magnificent looking tree as far as trees go. Sure it dropped pine needles that had to be cleaned up weekly but not to much of a problem UNTIL about a year later when we had a freek thunderstorm! When I went out the front door after the storm passed I was shocked to see about 1/2 of my yard and part of my roof completely brown covered in pine needles about an inch deep. That was enough and the demise of the tree

I spent the following week cutting down the mess making tree. I actually climbed up as high as I could and tied a rope even higher. With my 10 year old son pulling on the rope from far away I topped about 20’ with it falling towards the street. I was very nervous about the the bottom of the cut slipping back and knocking me out of the tree. Anyway, after that it took the rest of the week to cut it down to the stump. Since my yard is practically beach sand I dug out the stump down about 4’ I cut it off with a chainsaw.

I finally cut it up into fire wood and stacked it behind my toolshed. About a year later we had our first and last wood fire in the fireplace. It was a PITA to clean out the ashes. So I took the rest of the firewood out to a construction site I was working on and dumped it. Glad to see it gone. Others picked it up and took it home.

Anyway, that was my first and last one tree.

I’m not a “tree hugger”

lol

It's like a never ending flow of offal, or so it seems. But they're beautiful trees and it smells wonderful as a result of their presence.

Dan

100% Esco! I've owned a lot of different ones over the years, but I treated myself to a pair of Esco stands a few years ago. I got both the flat tops and bought a second set of "saddle" type U shaped tops. So one pair, and I can switch the type of top. I would and do trust my life with them.Anyone have a preferred Jackstand model? I'm seeing a lot of good reviews on these Esco ones and I love the flat tops vs the pinch weld style. Height is 'only' 21.5" but that should be enough for most jobs I do.

Amazon.com: Esco 10498 Jack Stands, 3 Ton Capacity, Pair of 2 Stands (Pack of 2), Silver : Automotive

Buy Esco 10498 Jack Stands, 3 Ton Capacity, Pair of 2 Stands (Pack of 2), Silver: Jack Stands - Amazon.com ✓ FREE DELIVERY possible on eligible purchaseswww.amazon.com

Harbor Freight now has a knock off of the Knipex Raptor Smooth Jawed Gripping Wrench, for about 1/2 the price of a Knipex.It's not in my tool box yet, but I just flew with a GE mechanic who had this set of Knipex pliers in his toolbox. Anyone know where I can buy one? Is MAC Tools the only distributor? After all, yesterday was payday.

Home page

[EDIT] Just ordered:

https://www.ebay.com/itm/KNIPEX-Hea...-Wrench-Nickel-Plating-86-03-180/282872476194

Admin edit: Also offered here:

Knipex 86 03 180 SBA $61.94 Pliers Wrench, 7 1/4 In | Zoro.com

https://www.amazon.com/Knipex-8603180-7-Inch-Pliers-Wrench/dp/B000X4KP1C

Smaller version too:

Knipex 86 03 150 $58.77 6" Mini Pliers Wrench, Plastic Grip | Zoro.com

The HF knockoff is an "Icon" brand (HF's premium line) and made in Taiwan.

The Icon version is called "PARROT" as opposed to Knipex "RAPTOR".

The use case I think is for gripping corroded or rounded off bolts

KNIPEX - https://www.amazon.com/KNIPEX-87-41...id=1662825837&sprefix=knipex+,aps,143&sr=8-17

HARBOR FREIGHT ICON - 10 in. Multi Slip-Joint Parrot Nose Pliers

With this weekend's sale (incidentally even though the coupon says limit 1 coupon per day, the cashier that helped me just scanned the coupon 5x for the 5 tools I bought):

The price ended up being just under $20.

I have recently discovered these 5 inch cutters - "DOYLE" from Harbor Freight. They are super sharp and they do a great job at cutting off the ends of nylon zip-ties WITHOUT leaving a sharp stub. I like these A LOT and the price is right:

www.harborfreight.com

www.harborfreight.com

www.harborfreight.com

www.harborfreight.com

I am not exactly sure what the black tab next to the blade on the $8.99 electronics side cutters is for though, other than to prevent the cut-off-piece from flying away.

5 in. Electronics Side Cutter

Amazing deals on this 5In. Electronics Side Cutter at Harbor Freight. Quality tools & low prices.

5 in. Precision Flush Cutter

Amazing deals on this 5In Precision Flush Cutter at Harbor Freight. Quality tools & low prices.

I am not exactly sure what the black tab next to the blade on the $8.99 electronics side cutters is for though, other than to prevent the cut-off-piece from flying away.

Last edited:

PLYWOOD

Yes I know plywood is so mundane. However I decided recently that I had enough of cluttering up my drawers with power tools and wanted to hang my power tools somewhere. I also didn't want to clutter up my wall space with hanging my power tools (wall space is at a premium) so I decided to slap a piece of plywood on the side of my cheapo Costco CSPS Tool Chest and hang my power tools from the plywood.

Conveniently, my tools chest had a handle on the side of it that was secured by 6x 10mm M1.0 bolts. I took off the handle and used longer bolts to secure the plywood, then hung my tools from the plywood. Problem solved! PS Bonus - $5 Craigslist score on the CRAFTSMAN vice (circa 1970s?) I picked up.

Yes I know plywood is so mundane. However I decided recently that I had enough of cluttering up my drawers with power tools and wanted to hang my power tools somewhere. I also didn't want to clutter up my wall space with hanging my power tools (wall space is at a premium) so I decided to slap a piece of plywood on the side of my cheapo Costco CSPS Tool Chest and hang my power tools from the plywood.

Conveniently, my tools chest had a handle on the side of it that was secured by 6x 10mm M1.0 bolts. I took off the handle and used longer bolts to secure the plywood, then hung my tools from the plywood. Problem solved! PS Bonus - $5 Craigslist score on the CRAFTSMAN vice (circa 1970s?) I picked up.

PLYWOOD

Yes I know plywood is so mundane. However I decided recently that I had enough of cluttering up my drawers with power tools and wanted to hang my power tools somewhere. I also didn't want to clutter up my wall space with hanging my power tools (wall space is at a premium) so I decided to slap a piece of plywood on the side of my cheapo Costco CSPS Tool Chest and hang my power tools from the plywood.

Conveniently, my tools chest had a handle on the side of it that was secured by 6x 10mm M1.0 bolts. I took off the handle and used longer bolts to secure the plywood, then hung my tools from the plywood. Problem solved! PS Bonus - $5 Craigslist score on the CRAFTSMAN vice (circa 1970s?) I picked up.

View attachment 153857

They use sanded Birch ply for sheathing out there don't they? Probably why housing costs so much.

Out here in the west we use regular ply, not sanded birch ply for sheathing, but c'mon, I don't want my garage to look totally jury-rigged-grade ---- I'm gonna use kinda-of-nice plywood in my garage!!!They use sanded Birch ply for sheathing out there don't they? Probably why housing costs so much.

Sig red vice, nice score!

@Jlaa - where did you get the brackets from for hanging your tools?PLYWOOD

Yes I know plywood is so mundane. However I decided recently that I had enough of cluttering up my drawers with power tools and wanted to hang my power tools somewhere. I also didn't want to clutter up my wall space with hanging my power tools (wall space is at a premium) so I decided to slap a piece of plywood on the side of my cheapo Costco CSPS Tool Chest and hang my power tools from the plywood.

Conveniently, my tools chest had a handle on the side of it that was secured by 6x 10mm M1.0 bolts. I took off the handle and used longer bolts to secure the plywood, then hung my tools from the plywood. Problem solved! PS Bonus - $5 Craigslist score on the CRAFTSMAN vice (circa 1970s?) I picked up.

View attachment 153857

Thanks!

Dan

There are a gazillion of them on Amazon and they are all very similar. This is the one I used on the top (with the captive shelf). Note that it was only $22 a few days ago (now it is in the 30s....) but look around on Amazon and I am sure you can find an identical one for cheaper.

This is the one on the bottom. Note that this is only $16.99 and you can apply a 10% coupon to get that price down. This one is stronger and uses thicker gauge metal than the top one, but it has less of a curve at the end of the "power tool hook" to prevent the tools from sliding off --- only a concern in earthquake country.

Just a heads up for anyone with Milwaukee m18 tools, only buy genuine Milwaukee batteries.

I wanted some extra ones for the heavy use I give my grinder and bought a couple of these about a year ago:

They have now both failed within days of each other and will not charge more than half way and the charger lights up as faulty.

Garbage.

I won't avail or their supposed warranty as I'll just get more garbage so I bought more genuine batteries and will junk these.

Buy cheap buy twice I should have known better. Having good luck with aftermarket batteries for my Dremil etc I thought it might be OK but clearly the off brand Milwaukee stuff is bogus.

I wanted some extra ones for the heavy use I give my grinder and bought a couple of these about a year ago:

They have now both failed within days of each other and will not charge more than half way and the charger lights up as faulty.

Garbage.

I won't avail or their supposed warranty as I'll just get more garbage so I bought more genuine batteries and will junk these.

Buy cheap buy twice I should have known better. Having good luck with aftermarket batteries for my Dremil etc I thought it might be OK but clearly the off brand Milwaukee stuff is bogus.

There are certainly times where I could use something like that but it probably wouldn't get used that often.

I can sort of understand this with modern trucks, as they're so high off the ground you probably can't reach much just standing next to or in front of them.

Dan

After spending an hour or two in moderate discomfort sprawled over the top of the engine with my face near the back of the M119 intake manifold, I was wishing for something similar to this. Not sure how much it would improve comfort, but might be worth a shot. Maybe I'll wait for a sale and give it a whirl.I can sort of understand this with modern trucks, as they're so high off the ground you probably can't reach much just standing next to or in front of them.

You could just build a scaffold out of lumber...make it larger and pad it and it would be way more comfortable. You could even take naps on itAfter spending an hour or two in moderate discomfort sprawled over the top of the engine with my face near the back of the M119 intake manifold, I was wishing for something similar to this. Not sure how much it would improve comfort, but might be worth a shot. Maybe I'll wait for a sale and give it a whirl.

Yes this is bad, I am glad I have a perfectly working version before this update.

Beware folks don't be buying this new one!!

It's a damn shame that Milwaukee products have always been amazingly powerful and well built for a PRC made product too. But they have quite clearly made a big cost cutting move there and it backfired. As described in that video the hammer size, output etc is identical but they eliminated a ball bearing race.

The guy / team who came up with that "new" design need fired so they don't start doing this with all their stuff which would be a damn shame as I am a big fan of Milwaukee tools and have bought alot of it over the years.

I already have about 100 spanners but not a small handy kit to grab with just the main spanners you use for brake jobs and similar.

I looked for a long time and really liked the holder design for these Facom spanners so went for the 12 peice set.

Facom tools are made in France as far as I am aware and these feel high quality.

I looked for a long time and really liked the holder design for these Facom spanners so went for the 12 peice set.

Facom tools are made in France as far as I am aware and these feel high quality.

What, no Whitworth wrenches?I looked for a long time and really liked the holder design for these Facom spanners so went for the 12 peice set.

Facom tools are made in France as far as I am aware and these feel high quality.

Dan

Apparently Milwaukee is doing the 100% right thing. Owning up to the problem and offering to replace all the new models with new guns designed the same as the old "version A" guns

Probably not my favourite garage tool (those are the Milwaukee impact guns I eventually succumbed to buying after talk here and elsewhere!) but certainly indispensable in the UK climate is my induction heater. It’s a last resort item, but most things yield when it is brought to bear. I started with a cheapo from Ali-Express but that went bang after a few years and a few hundred applications, so I bought an ex-demo GYS unit, built in France, and everything is so much more robust than on the Chinese version. It cost around £400, but having got used to having one I felt lost without it, and just getting a couple of seized bleed nipples out of calipers justifies the cost (to me, anyway!). There’s always cutting things and breaking things as an alternative, but I’d far rather things come apart the way they were intended to without road salt. It is far more controllable than a blowtorch and there is zero collateral damage as it is so localised.

I, too, am very intrigued! I looked up AE and I found this:@Stegel, do you have a link to your GYS induction heater?

EDIT --- here are some pictures of it in action. Fascinating! I had no idea such a thing exists.

EDIT -- HERE IS A VIDEO OF IT IN ACTION:

319262148327.mp4

View attachment O2IcveN3l40D5dfqQRi_319262148327_mp4_264_ld.mp4

Last edited:

The one JLAA found is exactly like the first one I had, right down to the case. It served well enough, and in fairness I may have broken it - I’d used it for nuts and bolts on cars (obviously!) but when reorganising the garage I wanted to move one of the outlets on my air compressor tank; I could not shift the threaded bung, I presumed due to whatever thread lock / sealant they had used, and when I tried the Ali-express heater it went bang, but perhaps the mass of the steel 150 litre tank was too much for it (if, indeed, this affects their working).

This is the one I have:

www.campbellmillertools.co.uk

www.campbellmillertools.co.uk

It is very much at the shallow end of their range, but feels substantial and the coils are heftier than the Chinese version. It can get a bleed nipple glowing red hot in about 20 seconds, but I’ve also used it to gently heat up a ferrule on a brake hose to save wrecking a hard to replace hardline. A tear down of my 560SEC is looming, and I know it will see quite some action there!

This is the one I have:

GYS 068643 Powerdeduction 10R (UK) Induction Machine

GYS 068643 Powerdeduction 10R (UK) Induction Machine The Powerduction 10R is designed to heat, unlock to enable removal of mechanical parts such as worn nuts and bolts in seconds. It is especially recommended in the automotive, agricultural, maintenance a

www.campbellmillertools.co.uk

www.campbellmillertools.co.uk

It is very much at the shallow end of their range, but feels substantial and the coils are heftier than the Chinese version. It can get a bleed nipple glowing red hot in about 20 seconds, but I’ve also used it to gently heat up a ferrule on a brake hose to save wrecking a hard to replace hardline. A tear down of my 560SEC is looming, and I know it will see quite some action there!

I've seen metalworking/blacksmith guys use these and wondered what they were. Theirs were big bench mounted ones they would stick a piece of stock into, but it's the same concept.

Pretty cool. I can see this being very helpful working on older cars, especially ones that have been in conditions that promote rust.

Dan

Pretty cool. I can see this being very helpful working on older cars, especially ones that have been in conditions that promote rust.

Dan

Last edited:

Very cool I knew of those machines but have never used one. This would fall into the bracket of "not used enough to justify the cost" for me personally. But great idea and the ability to heat just a bolt red hot but no naked flames or damage to surrounding area a huge advantage.This is the one I have:

GYS 068643 Powerdeduction 10R (UK) Induction Machine

GYS 068643 Powerdeduction 10R (UK) Induction Machine The Powerduction 10R is designed to heat, unlock to enable removal of mechanical parts such as worn nuts and bolts in seconds. It is especially recommended in the automotive, agricultural, maintenance awww.campbellmillertools.co.uk

I have dealt with (and continue to almost daily) soooo many fasteners which no longer identify as bolts I have 100% success rate and get them all out with a combination of:

- Hammer

- Bigger hammer

- All sizes of Irwin Vice grips including mini versions

- Sharp chisels and punches to shock them free and punch rounded cap bolts to turn etc

- Easy out sets - the spiral socket types are the only ones that work for me

- MAP blowlamp

- Sharp Pro titanium drill bits

- Welder - it will get any stuck or sheard off fastener out trust me. Blasts heat into any sheared bolt and provides a new nut to get purchase and wind it out. I use the welder regular on rounded or sheared bolts.

I can see this being very helpful working on older cars, especially ones that have been in conditions that promote rust.

Remember the good old days when there were only cis-fasteners?I have dealt with (and continue to almost daily) soooo many fasteners which no longer identify as bolts I have 100% success rate ...

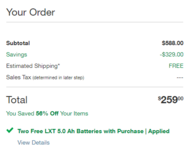

If you're in the Makita 18V ecosystem and need to grab a bunch of batteries, a really good deal deal just popped up at Ace Tool.

For $199 you get four (4) 5.0 LXT batteries as part of a big-boy (2x18v) circular saw kit. Includes a double charger and a bag.

Currently, (2) 5.0 batteries are $212 on AMZN and $229 at the Home Despot.

For $199 you get four (4) 5.0 LXT batteries as part of a big-boy (2x18v) circular saw kit. Includes a double charger and a bag.

Makita XSH06PT 36V (18V X2) LXT Brushless 7-1/4 in. Circular Saw Kit (5.0Ah) | Makita Tools

The Makita XSH06PT 18V X2 LXT Lithium‑Ion (36V) Brushless Cordless 7‑1/4 in. Circular Saw Kit (5.0Ah) has a long list of features for efficient cutting without the cord. The electronically-controlled brushless motor delivers a full 6,000 RPM for efficient cutting. Shop at Ace Tool and save today!

www.acetool.com

Currently, (2) 5.0 batteries are $212 on AMZN and $229 at the Home Despot.

Those are the ones I use, after many years with a cheap set. I used them on my recent rear SLS sphere replacement on my E500. Very happy with them. I would recommend them.Anyone have a preferred Jackstand model? I'm seeing a lot of good reviews on these Esco ones and I love the flat tops vs the pinch weld style. Height is 'only' 21.5" but that should be enough for most jobs I do.

That looks like a killer deal. Why do I have to be married to the M18 FUEL platform?If you're in the Makita 18V ecosystem and need to grab a bunch of batteries, a really good deal deal just popped up at Ace Tool.

For $199 you get four (4) 5.0 LXT batteries as part of a big-boy (2x18v) circular saw kit. Includes a double charger and a bag.

EDIT: Here is the FUEL equivalent of a "special buy"... saw, charger, case, and ONE 6.0Ah battery, for $299?:

Last edited:

They'll have some deals as the holidays approach, I'm sure. I hope. I could use some more (larger) batteries.That looks like a killer deal. Why do I have to be married to the M18 FUEL platform?

Dan

I have the opposite problem, after a couple of previous deals that came with extra batteries. I could use a cordless 7.25" saw but don't really need more batteries, although I guess I could resell extras on Craigslist. Then again, for the price, it might be hard to beat the Makita saw deal with FUEL equivalents.They'll have some deals as the holidays approach, I'm sure. I hope. I could use some more (larger) batteries.

I have a 6-1/2" 18v Makita circular saw. LOVE that damn thing. Only time I've reached for a larger or corded saw is for track sawing. The 7-1/4 unit in that deal is a pretty serious machine. Maybe not quite for production framing, but pretty damn close.

Four batteries for $200 is absolutely killer. I'm stocked full of batteries these days, else I'd be grabbing that deal.

I think I'm going to ask Santa to bring me a small top handle Makita battery chainsaw. I've got the larger 2X18 saw, and it's been really handy. My small Stihl has always been a shoulder-buster. No matter who has tried to service it.

Four batteries for $200 is absolutely killer. I'm stocked full of batteries these days, else I'd be grabbing that deal.

I think I'm going to ask Santa to bring me a small top handle Makita battery chainsaw. I've got the larger 2X18 saw, and it's been really handy. My small Stihl has always been a shoulder-buster. No matter who has tried to service it.

FYI - Ace Tool charges shipping, ~$40 to my address.If you're in the Makita 18V ecosystem and need to grab a bunch of batteries, a really good deal deal just popped up at Ace Tool.

For $199 you get four (4) 5.0 LXT batteries as part of a big-boy (2x18v) circular saw kit. Includes a double charger and a bag.

Currently, (2) 5.0 batteries are $212 on AMZN and $229 at the Home Despot.

Home Despot has the same Makita deal at a higher price ($260) with free shipping, your choice of top-handle saw or rear-handle saw. Local pickup may be available, my store has the rear-handle version and battery kit in stock, top-handle saw is not in stock. You may be able to return the saw kit or batteries, with the HD "loophole", if so inclined. Anyone have feedback on which [circular-saw] handle design is preferred? The rear-handle seems awfully long. Note that Ace has the rear-handle version for $260 shipped, same as HD.

Top handle:

Makita 18V X2 LXT Lithium-Ion (36V) Brushless Cordless 7-1/4 in. Circular Saw Kit 5.0Ah XSH06PT - The Home Depot

Disclose a fantastic and powerful tool to your workstation with the addition of this exclusive Makita X2 LXT Lithium-Ion Brushless Cordless Circular Saw Kit.

www.homedepot.com

Rear handle:

Makita 18V X2 LXT 5.0Ah Lithium-Ion (36V) Brushless Cordless Rear Handle 7-1/4 in. Circular Saw Kit XSR01PT - The Home Depot

Accomplish all your difficult cutting tasks easily by using this amazing Makita X2 LXT Lithium-Ion Brushless Cordless Rear Handle Circular Saw Kit.

www.homedepot.com

Last edited:

Rear handle is a long saw. think it comes w 14 or 16" bar. I've used it for some light trimming and bucking smaller logs. Also demo-ing a lot of oak board fencing last year. The top handle saw IIRC has a 10 or 12" bar. Better for trimming. Especially when working from a ladder or bucket or whatever. The 2X18v unit is surprisingly powerful. I'm not expecting the same from the small top handle unit.

I have the 6-1/2" M18 Milwaukee circular saw. I have continued to be amazed at how well it works and the limited battery consumption. I built a set of steps for an exterior deck back in September, and I was able to use it for nearly the full day doing cutoffs and such without changing a battery. It plowed through 2x6 and 4x4 cedar like it was buttah.I have a 6-1/2" 18v Makita circular saw. LOVE that damn thing. Only time I've reached for a larger or corded saw is for track sawing. The 7-1/4 unit in that deal is a pretty serious machine. Maybe not quite for production framing, but pretty damn close.

Four batteries for $200 is absolutely killer. I'm stocked full of batteries these days, else I'd be grabbing that deal.

I think I'm going to ask Santa to bring me a small top handle Makita battery chainsaw. I've got the larger 2X18 saw, and it's been really handy. My small Stihl has always been a shoulder-buster. No matter who has tried to service it.

Dan

Last edited:

Harbor Fright's latest email claims their Daytona clone 'beats' Esco:100% Esco! I've owned a lot of different ones over the years, but I treated myself to a pair of Esco stands a few years ago. I got both the flat tops and bought a second set of "saddle" type U shaped tops. So one pair, and I can switch the type of top. I would and do trust my life with them.

Bummer that Esco is no longer made in USA.

EDIT: More discussion here:

It was only a matter of time... | Tools and Shop Equipment

Today's email list Harbor Freight ad shows that they now have an ESCO clone jackstand. They do a head to head compare in the ad, like they usually do when they knock something off. "Daytona 3 ton Jack Stands with Circular Pads". $99.99 for a pair, compared to ESCO at $124.38. I could guess...

Last edited:

Where’s the line item for ‘Quality Related Recalls’?

I have had this balljoint splitter for years and at the weekend it bent trying to split a joint on my w140

That tool is scrap now and I have a balljoint still stuck. So I ordered a hydraulic type ball joint splitter with 8 tonne force. Will try it as soon as it arrives in the hope it will be up to the task!

That tool is scrap now and I have a balljoint still stuck. So I ordered a hydraulic type ball joint splitter with 8 tonne force. Will try it as soon as it arrives in the hope it will be up to the task!

I have had this balljoint splitter for years and at the weekend it bent trying to split a joint on my w140

View attachment 156522

That tool is scrap now and I have a balljoint still stuck. So I ordered a hydraulic type ball joint splitter with 8 tonne force. Will try it as soon as it arrives in the hope it will be up to the task!

View attachment 156523

When the other balljoint tool bent I knew to find a better solution and stop before damaging the good track rod end and potentially having to upset the steering geometry etc unnecessarily.

The 8 tonne hydraulic balljoint separator was the highest spec which would fit a car I could find and it arrived today.

Easy to use and first try the stuck joint popped free. Just a case of the right tool for the job!

The old tool is bent and will be binned but the strength difference is easy to see between the two. S classes do tend to have fairly large ball joints so this new tool will get good use.

Joe, I can see why you need that tool. The amount of rust you deal with is unbelievable.

When the other balljoint tool bent I knew to find a better solution and stop before damaging the good track rod end and potentially having to upset the steering geometry etc unnecessarily.

The 8 tonne hydraulic balljoint separator was the highest spec which would fit a car I could find and it arrived today.

Easy to use and first try the stuck joint popped free. Just a case of the right tool for the job!

View attachment 156546View attachment 156547

The old tool is bent and will be binned but the strength difference is easy to see between the two. S classes do tend to have fairly large ball joints so this new tool will get good use.

When I did my tie rod joints I used a pickle fork. One good smack and they were off but I had no rust to contend with. After reinstalling the new parts I did get a four wheel alignment. Which is still holding up

About the only good thing left in SoCal “The Perfect Weather”

lol

Similar threads

- Replies

- 5

- Views

- 215

- Replies

- 0

- Views

- 92

- Replies

- 28

- Views

- 2,063

Similar threads

- Replies

- 0

- Views

- 92

- Replies

- 28

- Views

- 2,063

- Replies

- 8

- Views

- 1,041