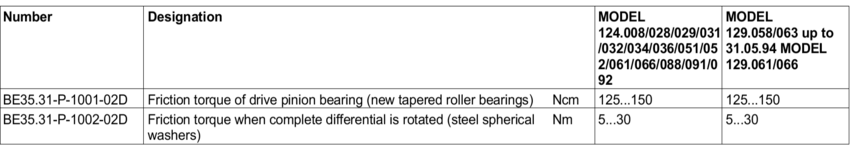

Hello, I've spent a decent amount of time digging around here and w124performance.com for case preload and backlash specs for a rear diff I'm installing a quaife LSD on. I've found a document titled diff_rebuild_FSM.pdf which seems to mostly refer to factory LSD and ASD models. There are specs listed for vertical and lateral run out (0.02mm) and I assume these are Mercedes speak for case backlash and case preload but I'm not positive. A point in the right direction is appreciated - I have a lot of experience rebuilding VW 5 and 6 speed manuals so maybe its just the terminology thats throwing me off.

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

034 Rear Diff Overhaul Specs

- Thread starter shearerbeard

- Start date