I have a 93 400E that sends a small amount of crankcase fumes into the distributors. It has153,000 miles on it, and runs perfectly. A manometer shows zero pressure reading at idle, and climbs to a half inch of water column at 1800 RPMs. Could someone tell me if the vapor cannister and its valves are supposed to maintain a negative pressure at an idle? Thanks

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

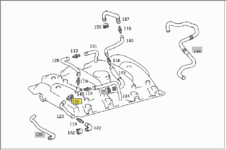

400E without negative crankcase pressure

- Thread starter alpineviking

- Start date