Postby gsxr on Wed Mar 18, 2009 2:13 am

My E420 air pump had been noisy, and this morning it seized up. Fortunately it happened immediately after I backed the car out of the garage, so I heard the ugly noises from the clutch, and shut off the engine. I disconnected the wire to the clutch, which allowed me to drive the car, but unfortunately the computer knows the pump isn't functioning and it triggers the dreaded Check Engine light.

In case you haven't looked, the price for rebuilt pumps is obscene... $350-$500, plus a core charge. The stupid thing only runs for 1-2 minutes after a cold start, and the only purpose is to help the catalyst heat up faster (which I could really care less about). The bearing is fine, I could leave the pump in place. The non-catalyst engines have an idler pulley in this location but the cost would be ~$250 USD plus S&H to order the bracket+pulley from Germany. But the bigger problem is the computer not being happy, and triggering the CEL on the dash.

Does anyone know how to fool the computers into not knowing the air injection is disabled? Better yet, an EPROM chip for the LH module from a non-catalyst version? I'd sure like to avoid the ~$400 repair bill (and several hours labor to R&R the POS).

:down:

Dave M.

Boise, ID

1995 E420 (W.I.P.)

1994 E500 (Q-ship)

1993 300D (Sportline)

1987 300D (Sportline Stage 2)

1987 300D (R.I.P)

Click here for my website photos, documents, and movies.

===================================

Postby NIIBE on Wed Mar 18, 2009 3:02 am

?????

?I had also removed my Air pump and am driving over 3years.

I have just plugged EGR holes by custum made blind plug and plate.

I do not do any modification according to ECU.

I think it would not cause by air pomp failure.

NIIBE

gsxr wrote:My E420 air pump had been noisy, and this morning it seized up. Fortunately it happened immediately after I backed the car out of the garage, so I heard the ugly noises from the clutch, and shut off the engine. I disconnected the wire to the clutch, which allowed me to drive the car, but unfortunately the computer knows the pump isn't functioning and it triggers the dreaded Check Engine light.

In case you haven't looked, the price for rebuilt pumps is obscene... $350-$500, plus a core charge. The stupid thing only runs for 1-2 minutes after a cold start, and the only purpose is to help the catalyst heat up faster (which I could really care less about). The bearing is fine, I could leave the pump in place. The non-catalyst engines have an idler pulley in this location but the cost would be ~$250 USD plus S&H to order the bracket+pulley from Germany. But the bigger problem is the computer not being happy, and triggering the CEL on the dash.

Does anyone know how to fool the computers into not knowing the air injection is disabled? Better yet, an EPROM chip for the LH module from a non-catalyst version? I'd sure like to avoid the ~$400 repair bill (and several hours labor to R&R the POS).

:down:

===================================

Postby gsxr on Wed Mar 18, 2009 3:05 am

NIIBE wrote:?????

?I had also removed my Air pump and am driving over 3years.

I have just plugged EGR holes by custum made blind plug and plate.

I do not do any modification according to ECU.

I think it would not cause by air pomp failure.

NIIBE

Niibe, what LH module part number are you using? How do you keep the Check Engine light from triggering? That's my main problem!

===================================

Postby 195910 on Wed Mar 18, 2009 1:20 pm

gsxr wrote:

Niibe, what LH module part number are you using? How do you keep the Check Engine light from triggering? That's my main problem!

Hi GSXR,

Had issues with this pump too, the bearing got shot, luckily someone here got the bearings for these. completely useless thing!.

We don't have the Check engine light.

195910

===================================

Postby gsxr on Wed Mar 18, 2009 2:57 pm

I wish mine was just a bad bearing. AFAICT, the bearing is fine, it's the pump internals that are shot. It doesn't turn smoothly like it should, it intermittently locks up. By comparison, the pump on my E500 turns very smoothly by hand. Stupid pump!

===================================

Postby gerryvz on Wed Mar 18, 2009 6:06 pm

Bearing.

Bite the bullet.

Replace pump with rebuild.

===================================

Postby Glen on Wed Mar 18, 2009 7:50 pm

gsxr wrote:I wish mine was just a bad bearing. AFAICT, the bearing is fine, it's the pump internals that are shot. It doesn't turn smoothly like it should, it intermittently locks up. By comparison, the pump on my E500 turns very smoothly by hand. Stupid pump!

My money is on the bearing but if yours is okay, then just gut the pump and leave it connected so the computer thinks its there.

===================================

Postby gsxr on Wed Mar 18, 2009 7:56 pm

Glen wrote:My money is on the bearing but if yours is okay, then just gut the pump and leave it connected so the computer thinks its there.

I was wondering about that. Doesn't the computer look at the O2 sensor readings, to determine if the pump is operating? If not, I could connect a dummy solenoid so it sees an electrical load - that's simple. I thought it would be more complicated. Hmmm. I'll check into that. Anyone have a junk pump they can loan me for an experiment?

About the bearing - at least one of the bearings is replaceable. A guy on Benzworld did that as a DIY, but I think it was the pulley bearing, not the internal pump bearing(s). The pulley (with clutch disengaged) rolls very smoothly, it's the pump center shaft that is iffy. I turned it by hand and had to use a wrench to "crunch" past whatvever was hold it up, and this morning on a cold start it ran normally (that is to say, audibly - it hasn't been quiet in the 1000 miles that I've owned the car). I still need a long term fix, either disable or replace, and I'm shooting for the cheap/free option if possible!

===================================

Postby 195910 on Wed Mar 18, 2009 8:04 pm

Can we use a shorter drive belt and bypass the pump?

195910

===================================

Postby gsxr on Wed Mar 18, 2009 8:25 pm

195910 wrote:Can we use a shorter drive belt and bypass the pump?

No, due to belt routing, a pulley is required in that location. Non-catalyst M119 engines have an idler pulley & bracket mounted in that position, as mentioned in my first post. My main problem is keeping the computers happy. I don't want a CEL on all the time, and I also would prefer not to pull the bulb, but that is an option....

===================================

Postby J. M. van Swaay on Wed Mar 18, 2009 9:00 pm

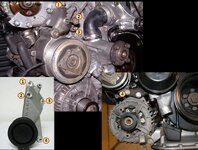

If the e420 pump is similar to the one on my wife's 94 E320 wagon, you might be able to repair the internals. I attached a picture of what all the parts look like. This one was making noise, I disassembled, cleaned, regreased, reassembled and reinstalled. It's been working quietly now for some time............

J. M. van Swaay

===================================

Postby omegabenz on Thu Mar 19, 2009 3:00 am

gsxr wrote:No, due to belt routing, a pulley is required in that location.

That can be arranged by making a mounting boss, and making/retrofitting a pulley.

I borrowed this pic from your other thread:

===================================

Postby gsxr on Thu Mar 19, 2009 4:26 am

well, (1) I believe it's not worth the R&D, when there are factory parts available for ~$250... and (2), based on the routing diagram below, I'm fairly certain it can't be done without totally changing the belt routing (and belt length), both things I would not want to do. ROI = zero.

I'll be happy if I can disable the thing and make the computer not throw a code. But I'll also look into just taking the pump apart, cleaning it up, and putting it back together. A free fix would definitely be in my budget!

You do not have the required permissions to view the files attached to this post.

Dave M.

Boise, ID

1995 E420 (W.I.P.)

1994 E500 (Q-ship)

1993 300D (Sportline)

1987 300D (Sportline Stage 2)

1987 300D (R.I.P)

Click here for my website photos, documents, and movies.

===================================

Postby will_968 on Thu Mar 19, 2009 5:37 am

gsxr wrote:No, due to belt routing, a pulley is required in that location. Non-catalyst M119 engines have an idler pulley & bracket mounted in that position, as mentioned in my first post. My main problem is keeping the computers happy. I don't want a CEL on all the time, and I also would prefer not to pull the bulb, but that is an option....

Mine was replaced with the non-cat idler and pulley. Didn't do the job myself (garage did it), but I've no engine light on, and they didn't tell me they needed to do anything to stop it coming on.

Will

'93 Mercedes E500

'94 Porsche 968 Sport

'08 Audi A6

===================================

Postby gsxr on Thu Mar 19, 2009 4:30 pm

will_968 wrote:Mine was replaced with the non-cat idler and pulley. Didn't do the job myself (garage did it), but I've no engine light on, and they didn't tell me they needed to do anything to stop it coming on.

Hmmm. I would LOVE to know how they managed that trick. You sure the CEL bulb wasn't removed? You still have an O2 sensor and catalysts, right?

You still have an O2 sensor and catalysts, right?

===================================

Postby need2speed on Thu Mar 19, 2009 6:48 pm

I think will is in Dubai, where non-cat models were available so they have both the parts and experience for this conversion. Say Dave, do you have p/n's for the non-cat pulley set-up? Maybe my next project...

need2speed

500E500 owners motto: "Lead, follow, or better yet, get out of the way."

===================================

Postby omegabenz on Thu Mar 19, 2009 7:08 pm

gsxr wrote:well, (1) I believe it's not worth the R&D, when there are factory parts available for ~$250... and (2), based on the routing diagram below, I'm fairly certain it can't be done without totally changing the belt routing (and belt length), both things I would not want to do. ROI = zero.

I'll be happy if I can disable the thing and make the computer not throw a code. But I'll also look into just taking the pump apart, cleaning it up, and putting it back together. A free fix would definitely be in my budget!

My point was that it can be done -whether that can be cost effective or not, that is up to the owner. Maybe S500R on MBworld is doing that delete to his racing engine/race car.

===================================

Postby gsxr on Thu Mar 19, 2009 7:10 pm

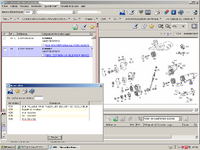

Non-cat pulley setup is found in EPC for Euro 124.034, Group 20, subgroup 045, callouts 74 and 80. Actually, it looks like the bracket (Sheave Pulley Console) comes with the idler pulley! Cool, that makes it easier - and cheaper, too:

119-230-03-42

Some different length bolts may be needed to attach it, you can see them in the EPC drawing.

===================================

Postby gsxr on Thu Mar 19, 2009 7:20 pm

omegabenz wrote:My point was that it can be done -whether that can be cost effective or not, that is up to the owner. Maybe S500R on MBworld is doing that delete to his racing engine/race car.

Almost anything can be done if you put the time, effort, and $$$ into it. The question is, is it worth it, and does it make sense. In this case, it really does not. The factory solution is simple, cheap, and retains the stock belt length as well.

:spinsmile:

===================================

Postby brams on Thu May 07, 2009 8:18 pm

Dave,

I'm jumping in late on this thread I know but my Euro E500 has the pump disconnected and it does not log a code in the LH module, my guess that on your car being US, that LH also does not log a code, I reckon that would be done by the diagnostic module which US cars have.

If you measured the resistance of the clutch and then put a resistor across it that might do the trick, you might want to use a big wattage and maybe stick it to a heat sink though in case it gets hot, I'd guess the windings of the clutch are lower resistance, maybe 10 ohms or less. Might pay you to use a 12v bulb instead.

I doubt that the O2 sensors are used to measure the effect of the pump working, seeing as the pump is used to oxidise the exhuast to light the CAT's off quicker then it stands to reason that the O2 sensors would not be feeding back for the same reason (they are not hot enough to work).

Glad you mentioned the bracket, I've been looking all over for that. As I want to throw the pump in the bin on my car.

95 E500 Limited

My E420 air pump had been noisy, and this morning it seized up. Fortunately it happened immediately after I backed the car out of the garage, so I heard the ugly noises from the clutch, and shut off the engine. I disconnected the wire to the clutch, which allowed me to drive the car, but unfortunately the computer knows the pump isn't functioning and it triggers the dreaded Check Engine light.

In case you haven't looked, the price for rebuilt pumps is obscene... $350-$500, plus a core charge. The stupid thing only runs for 1-2 minutes after a cold start, and the only purpose is to help the catalyst heat up faster (which I could really care less about). The bearing is fine, I could leave the pump in place. The non-catalyst engines have an idler pulley in this location but the cost would be ~$250 USD plus S&H to order the bracket+pulley from Germany. But the bigger problem is the computer not being happy, and triggering the CEL on the dash.

Does anyone know how to fool the computers into not knowing the air injection is disabled? Better yet, an EPROM chip for the LH module from a non-catalyst version? I'd sure like to avoid the ~$400 repair bill (and several hours labor to R&R the POS).

:down:

Dave M.

Boise, ID

1995 E420 (W.I.P.)

1994 E500 (Q-ship)

1993 300D (Sportline)

1987 300D (Sportline Stage 2)

1987 300D (R.I.P)

Click here for my website photos, documents, and movies.

===================================

Postby NIIBE on Wed Mar 18, 2009 3:02 am

?????

?I had also removed my Air pump and am driving over 3years.

I have just plugged EGR holes by custum made blind plug and plate.

I do not do any modification according to ECU.

I think it would not cause by air pomp failure.

NIIBE

gsxr wrote:My E420 air pump had been noisy, and this morning it seized up. Fortunately it happened immediately after I backed the car out of the garage, so I heard the ugly noises from the clutch, and shut off the engine. I disconnected the wire to the clutch, which allowed me to drive the car, but unfortunately the computer knows the pump isn't functioning and it triggers the dreaded Check Engine light.

In case you haven't looked, the price for rebuilt pumps is obscene... $350-$500, plus a core charge. The stupid thing only runs for 1-2 minutes after a cold start, and the only purpose is to help the catalyst heat up faster (which I could really care less about). The bearing is fine, I could leave the pump in place. The non-catalyst engines have an idler pulley in this location but the cost would be ~$250 USD plus S&H to order the bracket+pulley from Germany. But the bigger problem is the computer not being happy, and triggering the CEL on the dash.

Does anyone know how to fool the computers into not knowing the air injection is disabled? Better yet, an EPROM chip for the LH module from a non-catalyst version? I'd sure like to avoid the ~$400 repair bill (and several hours labor to R&R the POS).

:down:

===================================

Postby gsxr on Wed Mar 18, 2009 3:05 am

NIIBE wrote:?????

?I had also removed my Air pump and am driving over 3years.

I have just plugged EGR holes by custum made blind plug and plate.

I do not do any modification according to ECU.

I think it would not cause by air pomp failure.

NIIBE

Niibe, what LH module part number are you using? How do you keep the Check Engine light from triggering? That's my main problem!

===================================

Postby 195910 on Wed Mar 18, 2009 1:20 pm

gsxr wrote:

Niibe, what LH module part number are you using? How do you keep the Check Engine light from triggering? That's my main problem!

Hi GSXR,

Had issues with this pump too, the bearing got shot, luckily someone here got the bearings for these. completely useless thing!.

We don't have the Check engine light.

195910

===================================

Postby gsxr on Wed Mar 18, 2009 2:57 pm

I wish mine was just a bad bearing. AFAICT, the bearing is fine, it's the pump internals that are shot. It doesn't turn smoothly like it should, it intermittently locks up. By comparison, the pump on my E500 turns very smoothly by hand. Stupid pump!

===================================

Postby gerryvz on Wed Mar 18, 2009 6:06 pm

Bearing.

Bite the bullet.

Replace pump with rebuild.

===================================

Postby Glen on Wed Mar 18, 2009 7:50 pm

gsxr wrote:I wish mine was just a bad bearing. AFAICT, the bearing is fine, it's the pump internals that are shot. It doesn't turn smoothly like it should, it intermittently locks up. By comparison, the pump on my E500 turns very smoothly by hand. Stupid pump!

My money is on the bearing but if yours is okay, then just gut the pump and leave it connected so the computer thinks its there.

===================================

Postby gsxr on Wed Mar 18, 2009 7:56 pm

Glen wrote:My money is on the bearing but if yours is okay, then just gut the pump and leave it connected so the computer thinks its there.

I was wondering about that. Doesn't the computer look at the O2 sensor readings, to determine if the pump is operating? If not, I could connect a dummy solenoid so it sees an electrical load - that's simple. I thought it would be more complicated. Hmmm. I'll check into that. Anyone have a junk pump they can loan me for an experiment?

About the bearing - at least one of the bearings is replaceable. A guy on Benzworld did that as a DIY, but I think it was the pulley bearing, not the internal pump bearing(s). The pulley (with clutch disengaged) rolls very smoothly, it's the pump center shaft that is iffy. I turned it by hand and had to use a wrench to "crunch" past whatvever was hold it up, and this morning on a cold start it ran normally (that is to say, audibly - it hasn't been quiet in the 1000 miles that I've owned the car). I still need a long term fix, either disable or replace, and I'm shooting for the cheap/free option if possible!

===================================

Postby 195910 on Wed Mar 18, 2009 8:04 pm

Can we use a shorter drive belt and bypass the pump?

195910

===================================

Postby gsxr on Wed Mar 18, 2009 8:25 pm

195910 wrote:Can we use a shorter drive belt and bypass the pump?

No, due to belt routing, a pulley is required in that location. Non-catalyst M119 engines have an idler pulley & bracket mounted in that position, as mentioned in my first post. My main problem is keeping the computers happy. I don't want a CEL on all the time, and I also would prefer not to pull the bulb, but that is an option....

===================================

Postby J. M. van Swaay on Wed Mar 18, 2009 9:00 pm

If the e420 pump is similar to the one on my wife's 94 E320 wagon, you might be able to repair the internals. I attached a picture of what all the parts look like. This one was making noise, I disassembled, cleaned, regreased, reassembled and reinstalled. It's been working quietly now for some time............

J. M. van Swaay

===================================

Postby omegabenz on Thu Mar 19, 2009 3:00 am

gsxr wrote:No, due to belt routing, a pulley is required in that location.

That can be arranged by making a mounting boss, and making/retrofitting a pulley.

I borrowed this pic from your other thread:

===================================

Postby gsxr on Thu Mar 19, 2009 4:26 am

well, (1) I believe it's not worth the R&D, when there are factory parts available for ~$250... and (2), based on the routing diagram below, I'm fairly certain it can't be done without totally changing the belt routing (and belt length), both things I would not want to do. ROI = zero.

I'll be happy if I can disable the thing and make the computer not throw a code. But I'll also look into just taking the pump apart, cleaning it up, and putting it back together. A free fix would definitely be in my budget!

You do not have the required permissions to view the files attached to this post.

Dave M.

Boise, ID

1995 E420 (W.I.P.)

1994 E500 (Q-ship)

1993 300D (Sportline)

1987 300D (Sportline Stage 2)

1987 300D (R.I.P)

Click here for my website photos, documents, and movies.

===================================

Postby will_968 on Thu Mar 19, 2009 5:37 am

gsxr wrote:No, due to belt routing, a pulley is required in that location. Non-catalyst M119 engines have an idler pulley & bracket mounted in that position, as mentioned in my first post. My main problem is keeping the computers happy. I don't want a CEL on all the time, and I also would prefer not to pull the bulb, but that is an option....

Mine was replaced with the non-cat idler and pulley. Didn't do the job myself (garage did it), but I've no engine light on, and they didn't tell me they needed to do anything to stop it coming on.

Will

'93 Mercedes E500

'94 Porsche 968 Sport

'08 Audi A6

===================================

Postby gsxr on Thu Mar 19, 2009 4:30 pm

will_968 wrote:Mine was replaced with the non-cat idler and pulley. Didn't do the job myself (garage did it), but I've no engine light on, and they didn't tell me they needed to do anything to stop it coming on.

Hmmm. I would LOVE to know how they managed that trick. You sure the CEL bulb wasn't removed?

===================================

Postby need2speed on Thu Mar 19, 2009 6:48 pm

I think will is in Dubai, where non-cat models were available so they have both the parts and experience for this conversion. Say Dave, do you have p/n's for the non-cat pulley set-up? Maybe my next project...

need2speed

500E500 owners motto: "Lead, follow, or better yet, get out of the way."

===================================

Postby omegabenz on Thu Mar 19, 2009 7:08 pm

gsxr wrote:well, (1) I believe it's not worth the R&D, when there are factory parts available for ~$250... and (2), based on the routing diagram below, I'm fairly certain it can't be done without totally changing the belt routing (and belt length), both things I would not want to do. ROI = zero.

I'll be happy if I can disable the thing and make the computer not throw a code. But I'll also look into just taking the pump apart, cleaning it up, and putting it back together. A free fix would definitely be in my budget!

My point was that it can be done -whether that can be cost effective or not, that is up to the owner. Maybe S500R on MBworld is doing that delete to his racing engine/race car.

===================================

Postby gsxr on Thu Mar 19, 2009 7:10 pm

Non-cat pulley setup is found in EPC for Euro 124.034, Group 20, subgroup 045, callouts 74 and 80. Actually, it looks like the bracket (Sheave Pulley Console) comes with the idler pulley! Cool, that makes it easier - and cheaper, too:

119-230-03-42

Some different length bolts may be needed to attach it, you can see them in the EPC drawing.

===================================

Postby gsxr on Thu Mar 19, 2009 7:20 pm

omegabenz wrote:My point was that it can be done -whether that can be cost effective or not, that is up to the owner. Maybe S500R on MBworld is doing that delete to his racing engine/race car.

Almost anything can be done if you put the time, effort, and $$$ into it. The question is, is it worth it, and does it make sense. In this case, it really does not. The factory solution is simple, cheap, and retains the stock belt length as well.

:spinsmile:

===================================

Postby brams on Thu May 07, 2009 8:18 pm

Dave,

I'm jumping in late on this thread I know but my Euro E500 has the pump disconnected and it does not log a code in the LH module, my guess that on your car being US, that LH also does not log a code, I reckon that would be done by the diagnostic module which US cars have.

If you measured the resistance of the clutch and then put a resistor across it that might do the trick, you might want to use a big wattage and maybe stick it to a heat sink though in case it gets hot, I'd guess the windings of the clutch are lower resistance, maybe 10 ohms or less. Might pay you to use a 12v bulb instead.

I doubt that the O2 sensors are used to measure the effect of the pump working, seeing as the pump is used to oxidise the exhuast to light the CAT's off quicker then it stands to reason that the O2 sensors would not be feeding back for the same reason (they are not hot enough to work).

Glad you mentioned the bracket, I've been looking all over for that. As I want to throw the pump in the bin on my car.

95 E500 Limited