Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management -

DISCLAIMER

500Eboard, including its owner, administrators and moderators do not endorse, approve or support any claims provided by sellers as to vehicle condition, history, title status or mechanical operation.

Forum members/sellers are fully responsible for the accurate representation of all vehicles and/or parts they list and describe for sale on this forum. 500Eboard is not legally liable or responsible for sellers who misrepresent their vehicles per US Federal, State and local laws and regulations pertaining to proper and accurate vehicle sales.

Thank you

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FOR SALE GROUP BUY: Mercedes 500E Badge

- Thread starter Ntrepid

- Start date

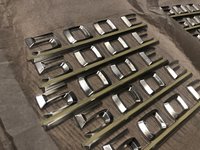

I reached out to get a status on the CNC and they have completed 55 units and remain on track to deliver on time and possibly early.

The other resources for subsequent steps (chroming, painting) are queued up and ready when these parts become available.

Robert

Last edited:

The order has shipped! Interesting as @Melville asked me yesterday what the latest was and I said I was waiting for it to go into the Inspection stage but then this ^^^ happened.

It does not show tracking information yet but I am expecting it will be middle of next week depending on where the shipment originates. Can't wait to see them. Will start coordinating with the next handler in this endeavor.

I believe the longest wait is behind us. More frequent updates too.

Robert

This is what you have been waiting for! The CNC aluminum badges are in and they look phenomenal. They have a really nice weight to them and I am super excited with how they turned out.

I've already reached out to the chromer to set a time to deliver the badges. In the meantime, I picked up some 3M plater's masking tape which is a polyurethane tape used to cover areas where you do not want chrome. The tape is resistant to the harsh chemicals in chroming baths. The intent there is to keep the machined aluminum for the black textured stripe which will painted on after chroming and will ensure maximum adhesion.

BTW, the people who opted for a badge to not be chromed I think are really going to like the result. In fact, if you look at the second picture, the aluminum badge makes the chrome one look black (Note: my ceilings are white so this is not something being picked up from in the room).

Robert

Let me look into this option. I remember you asking this and at the time I thought anodizing black was a viable solution. I’ll let you know.@Ntrepid Quick question. At an earlier time, I thought I saw there may be an option for Black Finish as well. Can you please clarify what final options we have? I originally requested 1 chrome and 1 black. If black is not an option, I'll just go with both chrome.

Robert

Last edited:

Looks like they turned out very nicely. I think there is going to be a lot of folks on the forum, in the future, who will rue the day when they didn't order a repro badge or two. And some folks who ordered extra badges now, who will be selling their extras for high prices in the future. Nice work !!

No reason as long as the volumes can get to the level of the first purchase to ensure the pricing is commensurate. Obviously, fewer units will mean a higher per badge price.Is there a reason why a second run would not be initiated if there is interest?

Robert

I’ll know better when I meet with the chromed this week. Remember that the next steps are:Too wich point i can espekt the delivery??

- Chroming the badge

- Painting the textured pinstripe

- Package and ship

Robert

Vous êtes le bienvenu, Franck!bonjour, et Merci pour ces infos ! très bien , pour comprendre la situation !! franck

Robert

67 badges prepped with plating tape and will be taken 1.5 hours south to Fredericksburg, VA, where they will be chromed. The chromer offered to pick them up sometime next week but I wanted to get them in his hands sooner.

@sheward will be the first to get his badge since he decided to get a bare aluminum badge with no black pinstripe. Anxious to hear his feedback. His package leaves tomorrow!

BTW, if someone would like to change their badge to be bare, now is the time to let me know! The table reflects everyone who has requested a bare aluminum badge.

Robert

Last edited:

Here you go! I found a video of a rim being CNC-machined. Same concept as the badge except a robotic arm probably suspended the blank which became the badge since it required cutting on all sides.Since I am kind of a tech-freak I would love to see how they did the machining, but that's probably company proprietary.

Robert

That request will be granted. In fact, my plan is to layout 9 reproductions abe 1 OEM to see if people can spot the OEM in the picture. Maybe we’ll vote on it.Would be neat to see one of these new badges right next to an original 500E badge in a high def pic.

Robert

I'm not one that delights in being first in things but since I am a "FIRST!" is in order. I just opened up the package an hour ago. The badge looks excellent. An exact reproduction as far as I can tell. The bare aluminum has a matted sheen that I knew would look nice. Microscopic machining marks are visible in places under very close scrutiny which does nothing to detract from the piece for me. Not sure if the chroming process will make this imperceptible. I think it will. The back edges of the badge are actually MORE accurate than the OEM plastic which is flawed because it is molded. This should enhance the look overall when set against paint. The adhesive tape is an exact match to the outline. I forgot to ask for two more of these strips to remount my OEM badges although I may be able to get them from kwontomspeed since He is local to me. I am VERY pleased with the results.!

drew

drew

There may be a sub-market for custom-outlined, pre-cut adhesive tape that could be used to re-mount old badges that were removed for paint jobs... hmmm.....I forgot to ask for two more of these strips to remount my OEM badges although I may be able to get them from kwontomspeed since He is local to me. I am VERY pleased with the results.!

One would have to validate that it was a genuine respray and not for purposes of cloaking. Otherwise could become a helpful tool to flag the culprits.There may be a sub-market for custom-outlined, pre-cut adhesive tape that could be used to re-mount old badges that were removed for paint jobs... hmmm.....

So happy to hear you are happy with the product, Drew.Microscopic machining marks are visible in places under very close scrutiny which does nothing to detract from the piece for me. Not sure if the chroming process will make this imperceptible. I think it will.

I drove 2 hours down on I95 on Friday night to the shop in Fredericksburg (VA) which will do the hexavalent chroming (Note: this is the environmentally-unfriendly, proper “old school” chroming versus trivalent which is newer) and the shop owner looked at the badges, noticed the same thing, and said, “Our prep work will take care of this before it hits the chrome bath.”

@kwontumspeed may have a new revenue stream on his hands!

Robert

There may be a sub-market for custom-outlined, pre-cut adhesive tape that could be used to re-mount old badges that were removed for paint jobs... hmmm.....

One would have to validate that it was a genuine respray and not for purposes of cloaking. Otherwise could become a helpful tool to flag the culprits.

Robert - you will be stone rich now! What shall you do with all that money?

Attachments

bonjour Robert, je reviens vers vous, s'il y a un surcoût, faites le moi savoir pour payer les surcoûts! Avez-vous une idée du délai de livraison? Merci pour cette information! franckTellement heureux d'apprendre que vous êtes satisfait du produit, Drew.

J'ai conduit 2 heures sur la I95 vendredi soir à la boutique de Fredericksburg (VA) qui effectuera le chromage hexavalent (Remarque: il s'agit du chromage «old school» proprement non respectueux de l'environnement par rapport au trivalent qui est plus récent) et le propriétaire du magasin a regardé les badges, a remarqué la même chose et a dit: "Notre travail de préparation s'en chargera avant qu'il n'atteigne le bain de chrome."

[USER = 377] @kwontumspeed [/ USER] peut avoir une nouvelle source de revenus entre les mains!

Robert

Google Translatebonjour Robert, je reviens vers vous, s'il y a un surcoût, faites le moi savoir pour payer les surcoûts! Avez-vous une idée du délai de livraison? Merci pour cette information! franck

hello Robert, I will get back to you, if there is an additional cost, let me know to pay the additional costs! Do you have any idea of the delivery time? Thank you for this information! franck

Last edited:

Any update on when these will be shipped? IT would be great to have for Spring.So happy to hear you are happy with the product, Drew.

I drove 2 hours down on I95 on Friday night to the shop in Fredericksburg (VA) which will do the hexavalent chroming (Note: this is the environmentally-unfriendly, proper “old school” chroming versus trivalent which is newer) and the shop owner looked at the badges, noticed the same thing, and said, “Our prep work will take care of this before it hits the chrome bath.”

@kwontumspeed may have a new revenue stream on his hands!

Robert

I wanted to update everyone on the latest with this project. It has been a just over 4 weeks since I went to Fredericksburg to deliver the badges to the shop which will do the hexavalent chroming. I had hoped to have picked them up by now and taken them to the painter. Unfortunately in that time, the shop had to close due to a COVID exposure which explained why I could not get in touch with them for over 1.5 weeks since no one was at work.

Since then they have gotten back to work and have prepped the pieces for copper plating (FYI - proper chroming starts with a copper plate followed by a nickel plate which is then capped with a chrome plating). Prepping the pieces for copper plating includes removing any marks left by the CNC machine so that they will not be magnified through each step in the plating process. Note that the decision was made to remove the plater’s tape which I had applied and plate the entire badge for better resiliency/weathering. The plating where the painted stripe will go now will be etched. I have purchased an etching pen and an etching chemical to properly prep the surface to take paint. I’m very confident this will give the right amount of adhesion for the paint.

The issue that the shop has run into is hanging the pieces in the bath. on larger pieces like a bumper, there is usually a hole where it can be hung. That is an area which typically is hidden so any markings left by the hanger are hidden from sight. The challenge with the badges is the badge does not have a place to hang it which will be hidden. Of course, the frustrating thing is I offered to have a tab feature added as part of the CNC machining which could be bent and broken off post chroming but the shop said that was unnecessary (hindsight is 20/15). The solution they hjave come up with is to add a small piece of tape to the recessed rear of the badge to attach to a jig for submersion in the bath. Where the tape attaches will be covered by the double sided adhesive in the final product.

I’m due for a check in call with them tomorrow but I wanted to keep everyone up to date as to the latest progress. I hope to have a date set tomorrow which I will be able to pick them up to take the the painter.

Robert

That’s a great skit! She was a funny ladyJoan Rivers also has a practical view on Banana's

Go to 5:15 in this clip, (her last bit of this show)

Thanks for the update Robert. I have a badge but it's not correct for my model year, 1992. Interestingly, my car was specified with a CODE 260 "Type Designation on Trunk Lid - Elimination" Guess the original owner wanted to remain in stealth mode!

I wanted to update everyone on the latest with this project. It has been a just over 4 weeks since I went to Fredericksburg to deliver the badges to the shop which will do the hexavalent chroming. I had hoped to have picked them up by now and taken them to the painter. Unfortunately in that time, the shop had to close due to a COVID exposure which explained why I could not get in touch with them for over 1.5 weeks since no one was at work.

Since then they have gotten back to work and have prepped the pieces for copper plating (FYI - proper chroming starts with a copper plate followed by a nickel plate which is then capped with a chrome plating). Prepping the pieces for copper plating includes removing any marks left by the CNC machine so that they will not be magnified through each step in the plating process. Note that the decision was made to remove the plater’s tape which I had applied and plate the entire badge for better resiliency/weathering. The plating where the painted stripe will go now will be etched. I have purchased an etching pen and an etching chemical to properly prep the surface to take paint. I’m very confident this will give the right amount of adhesion for the paint.

The issue that the shop has run into is hanging the pieces in the bath. on larger pieces like a bumper, there is usually a hole where it can be hung. That is an area which typically is hidden so any markings left by the hanger are hidden from sight. The challenge with the badges is the badge does not have a place to hang it which will be hidden. Of course, the frustrating thing is I offered to have a tab feature added as part of the CNC machining which could be bent and broken off post chroming but the shop said that was unnecessary (hindsight is 20/15). The solution they hjave come up with is to add a small piece of tape to the recessed rear of the badge to attach to a jig for submersion in the bath. Where the tape attaches will be covered by the double sided adhesive in the final product.

I’m due for a check in call with them tomorrow but I wanted to keep everyone up to date as to the latest progress. I hope to have a date set tomorrow which I will be able to pick them up to take the the painter.

Robert

All the best,

Joe

I spoke with the shop and they are close to completing the chrome plating. Their current projection is end of this week or early next. They indicated that the work effort to complete the job they underestimated.

The next step will be to etch and send for painting which leve the final step - FULFILLMEN!!! I know his has been a long journey and I appreciate your sticking with me through this.

Robert

follow the link and look at the attachment in post #2Does anyone have available a diagram with the measurements as to the exact location on where within the edge of the trunk lid to install a 500E badge? Is there any difference as to location placement for a E500 badge?

E500 Trunk Badge Location | Appearance and Detailing

I cant really figure where to position E500 badge! Are there any measurements from various points of the trunk? I would really appreciate if anyone can help out. Thanks.

www.500eboard.co

WOW! That's a great score... loved that build. Will you be posting a new OWNER thread?Thank you for the quick tip. Just bought Albert's (AS Design) blue, modified '93 and I have a few changes to it in mind...

Yes - I have a list of 15+ changes to it and receiving it this Saturday. But, I have parts being shipped from all over (UK, Latvia, Ukraine, etc.) and I am at the mercy of my friend who would be doing all the work to it. He's always really busy, so it might be a few weeks before everything arrives and I can take it to get it transformed into my vision for it. I also hooked up yesterday at a car show with one of Renntech's people who are located 45 mins. away in Stuart.

The chroming of the badges is complete!!! I am trying to find time this week to make the 1.5 hour drive down to Fredericksburg (VA) to inspect and pick them up. It may end up that it will be this weekend before I can get there but I will keep you posted with pictures of the badges in this 2nd to last stage before fulfillment.

This, by far has been the longest step in the process. The challenges the badge presented with (1) having no area to handle it without marring the finish as well as the (2) hand finishing prior to copper, nickel, and chrome baths were time consuming. Layer in the COVID protocol too to make for one long wait for this milestone.

Next up is I will be etching the chrome to ensure adhesion of the painted and textured black strip below the 500E. The plan is to drop this off NLT this weekend. This means that fulfillment is the only thing standing between you and getting this machined aluminum badge.

BTW, there are a few who people who have fallen out of the process so there are a few badges to be had. if there is interest, please PM me.

Robert

For the current investors of this Group Buy, here is a sample the chromed piece sent by the shop. To channel a commercial “Is it live or is it Memorex”

Hooefully this quells any concerns on the quality of the product. This should be considered OEM+ since it is made of better core materials (aluminum vs. plastic)

Robert

Similar threads

- Replies

- 90

- Views

- 5,749

- Replies

- 0

- Views

- 129

Similar threads

- Replies

- 0

- Views

- 129

- Replies

- 6

- Views

- 1,187