Update on the w140 stuck doors, the plan worked out perfect and I got both back doors opened for the first time since 2019 IIRC! The small drill hole I tried to shoot oil in through before was used to put in a coat hanger and watch on the endoscope and click the stuck pin into correct place then as soon as the doors opened I took the doors off and lubricated the locks within.

The doors are locking and unlocking perfectly now and handles functioning again.

I thought the MOT was 18th but its the 13th! And I am going to try to make it which will be crazy tight given the amount of work left but I'll try.

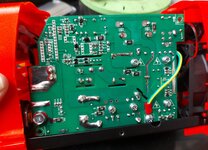

I did go ahead and get the front brake calipers off and 48 hrs in electrolysis rust removal. I got all pistons out but one was badly seized. It fought for over an hour but lost on the end up and came out! I used my press and brake piston slide hammer kit to work it in and out and had to use alot of heat and oil. Bores are perfect so I can restore my cores but the one seized piston has visible corrosion damage on the chrome so I have ordered a new piston to replace that bad one.

The doors are locking and unlocking perfectly now and handles functioning again.

I thought the MOT was 18th but its the 13th! And I am going to try to make it which will be crazy tight given the amount of work left but I'll try.

I did go ahead and get the front brake calipers off and 48 hrs in electrolysis rust removal. I got all pistons out but one was badly seized. It fought for over an hour but lost on the end up and came out! I used my press and brake piston slide hammer kit to work it in and out and had to use alot of heat and oil. Bores are perfect so I can restore my cores but the one seized piston has visible corrosion damage on the chrome so I have ordered a new piston to replace that bad one.