Following up on this thread.

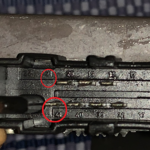

I was able to solve the issue by cleaning the clutch. Evidently I had flushed some dirt and grime into the air gap between the clutch and pulley last year whilst cleaning the front of the engine.

However, I was not satisfied with the fix, and seeing that the compressor was original, and I’d never really done A/C work in the past, I decided to challenge myself a bit and replace the compressor. I did not have strong confidence in this old compressor nor that the problem would return at some point.

I am happy to report two things:

1. The A/C system is making ice cubes out the dash vents, even in 90+F ambient temps. I am very happy with the results.

2. The fact that I caught the low-speed fan not working (blown fuse) is resulting in noticeably cooler running temps. In 90+F ambient temps, With the A/C system running, I am now seeing indicated engine coolant temps at 90-95C. This is under high load. Sitting at stoplights, temp creeps up to 95C indicated. I have not seen 100C indicated since restoring function of the low-speed fans.

When low-speed fans were not operating, I would see 100C and even 105C indicated temp in high ambients, with A/C operating and at long stoplight/extended idle.

So I believe the low-speed fan operation is worth 5-10C of temp mitigation in higher ambient temp environments. I still believe that A/C operation adds ~5C to engine temp all other things equivalent.

Anyway, I call this item closed now, and am exceedingly happy with the results.

I was able to solve the issue by cleaning the clutch. Evidently I had flushed some dirt and grime into the air gap between the clutch and pulley last year whilst cleaning the front of the engine.

However, I was not satisfied with the fix, and seeing that the compressor was original, and I’d never really done A/C work in the past, I decided to challenge myself a bit and replace the compressor. I did not have strong confidence in this old compressor nor that the problem would return at some point.

I am happy to report two things:

1. The A/C system is making ice cubes out the dash vents, even in 90+F ambient temps. I am very happy with the results.

2. The fact that I caught the low-speed fan not working (blown fuse) is resulting in noticeably cooler running temps. In 90+F ambient temps, With the A/C system running, I am now seeing indicated engine coolant temps at 90-95C. This is under high load. Sitting at stoplights, temp creeps up to 95C indicated. I have not seen 100C indicated since restoring function of the low-speed fans.

When low-speed fans were not operating, I would see 100C and even 105C indicated temp in high ambients, with A/C operating and at long stoplight/extended idle.

So I believe the low-speed fan operation is worth 5-10C of temp mitigation in higher ambient temp environments. I still believe that A/C operation adds ~5C to engine temp all other things equivalent.

Anyway, I call this item closed now, and am exceedingly happy with the results.