Well, I got impatient and ended up rebuilding the main lift cylinders and bow extension cylinders before the event and the top and roll bar were again working perfectly.

The Gem State Gambler 500 was this past weekend. It was a ton of fun and the Offroadster did great. The revised rear suspension was terrific. Handled the rough terrain wonderfully.

This year's route took us through the mointains of central Idaho from just outside Lowman, Idaho up to Deadwood Reservoir, and the old abandoned Deadwood Mine, over Pinyon Peak, and on to Yankee Fork.

Starting from the Payette river, we climbed north, past several active forest fires, until we eventually reached the Deadwood Dam and its reservoir. We checked out the dam, and then continued along the east side of the reservoir, through a couple water crossings, and on to the old Deadwood Mine site.

Deadwood Mine is a pretty cool old mining camp. Several large structures still stand in the area, but they are in rough shape at this point.

The adventurous can do a little further exploring in the area and may discover this incredible waterfall hidden nearby.

From there we headed east and climbed up to Pinyon Peak at an elevation of 9945 feet. The SL was the only Gambler car to make it to the very top. Everyone else struggled so much just to reach the ridge line, and elected not to attempt the road to the summit lookout.

When we reached the summit we were greeted by a very friendly forest ranger who was puzzled and amused by the presence of a Mercedes convertible at the top of his mountain. He told us in all his years working fire lookout towers, he'd never seen anyone bring a vehicle like that to the top. He came out and took pictures of the car to share with his colleagues.

When we went up to the peak, the rest of the Gamblers continued on down the back side of the mountain. We were capable of traveling much faster than most of them, so we told them we'd just catch up with them on the way down.

That was both a good and bad decision. Once we said goodbye to our new Forest Ranger friends, we took off and started ripping down the mountain to catch up with the rest of our group. That was a ton of fun. Basically my own private offroad race course. I had the ASR turned off and the rear suspension raised all the way up and basically rally drifted my way all the way down the mountain. I mentioned before that we expected the automatic rollbar to get quite the workout on the trip. We had been counting rollbar deployments through the whole trip. We got to 10 on the way down the mountain, and then towards the bottom we reached a particularly rocky section that I hit with just a bit too much speed. The front skid plate slammed over the rocks and the car kind of bounced, and then the rear came down hard on the rocks. The roll bar deployed, and the car kept on moving with no major issues, but I could hear an exhaust leak, and then when I tried to lower the roll bar for the 11th time, it was unresponsive.

Oh well, I figured I'd done some damage, but the car was still running and driving fine, so we continued on like true Gamblers.

Part of the route took us through the Frank Church Wilderness area. Motorized travel is forbidden in wilderness areas, but there are some primitive trails that predate the creation of the wilderness designation where motor vehicles can continue to travel as long as they stick to the trail.

Eventually we made it out of the wilderness and down to the old abandoned Yankee Fork mining area where we camped for the night.

This year's trophy was awarded to a guy who brought his daily driver bone stock 20 year old Volkswagen Golf diesel and managed to make it all the way over the peak. That was a real Gambler move. There was a real possibility that he would not be making it to work on Monday, but he sent it anyway and made it.

The next morning after breakfast we packed up camp and parted ways. My codriver and I decided to check out a few noteworthy historical sites on the way back home. After lunch, we got gas in a little town and headed for Boise, expecting the adventure was over.

About 15 miles down the highway we saw a couple Gamblers pulled over in a turnout, so we stopped to check and make sure they were ok. Turns out one had run out of gas and was filling up from their spare gas cans. Two others had stopped to check on them before me. Moments later another Gambler pulled up to check on things. So at this point there are 5 Gambler cars on the side of the highway.

Suddenly we hear a bang and a horrible scraping noise. A truck towing a 5th wheel camper up the highway then pulled into the turnout next to us with big chunks of aluminum siding hanging off the side of his trailer. Turns out the camper had seen better days and had chosen that exact moment to unzip itself and start falling apart.

Conveniently, Gamblers expect vehicular carnage and come prepared, so this guy was in luck. We had the siding resecured with wood screws and duct tape within about 20 minutes and sent the guy on his way.

When I got back I put the car on the lift and inspected the damage. In no particular order:

The exhaust pipe is crushed and split open under the cv axle

Both rear control arm limit sensors for the roll bar are broken in half

The cv axle boots are rubbing the air shock bags and have grooved them. They still hold air for now but maybe not for long.

The front left strut is 100% blown out. The right side is not far behind.

And the steering box is leaking pretty badly.

Not too bad, all things considered. It's all fixable, and it highlights where the weak points on the car were. I'll figure out a way to either upgrade, redesign, or protect each of these vulnerable parts to hopefully prevent similar damage in the future.

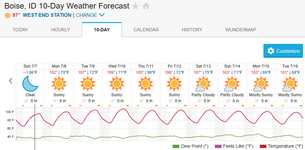

The next event is in early September, so I have just over a month to prepare.