Hello guys,happy to be part of this forum,lots of knowledge and very helpful threads.Im a happy owner of few c36 AMG left equipped with a 722.328 transmission.Its been few years since I started to experience the failure of reverse and multiple oil leaks.Been looking for some time after either a low mileage used transmission or rebuild mine.I ended up founding a very low mileage good trans 46k miles and pull the trigger.Even though it was a low mileage trans I decided to change all external seals (o rings vacuum modulator etc) all parts genuine from Mercedes including oil pump seals and also removed 7springs from the reverse piston.

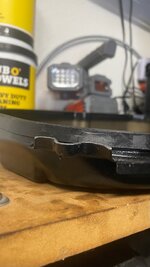

Long story short im experiencing oil leak coming from the driver side middle pan bolt and rear bolts of the pan,imo rear bolts get wet from the starting point leak and its just trickling.I changed the oil pan with a new one from dealer(horrible quality) none of the ears was straight,went through 2 pan gaskets already,did use a torque wrench for every bolt in the transmission...and leak it’s still there. One of the test ports aluminum washer wasn’t sealing properly i did change that too (I thought that’s the culprit) but leak is still there. I ended up cutting down the transmission ears all around when i saw how crooked they were to make sure oil pan gasket seats even all around still leaking.

Now idk could the neutral switch shaft seal to leak even though I changed that too when trans was out,straight forward job took off the seal and tapped new one with a deep socket all the way down,didn’t seem to leave room for doubts,other than that any inputs are very welcome since im running out of what could cause this leak.I personally the way it looks im still blaming the oil pan gasket.Thank you

Long story short im experiencing oil leak coming from the driver side middle pan bolt and rear bolts of the pan,imo rear bolts get wet from the starting point leak and its just trickling.I changed the oil pan with a new one from dealer(horrible quality) none of the ears was straight,went through 2 pan gaskets already,did use a torque wrench for every bolt in the transmission...and leak it’s still there. One of the test ports aluminum washer wasn’t sealing properly i did change that too (I thought that’s the culprit) but leak is still there. I ended up cutting down the transmission ears all around when i saw how crooked they were to make sure oil pan gasket seats even all around still leaking.

Now idk could the neutral switch shaft seal to leak even though I changed that too when trans was out,straight forward job took off the seal and tapped new one with a deep socket all the way down,didn’t seem to leave room for doubts,other than that any inputs are very welcome since im running out of what could cause this leak.I personally the way it looks im still blaming the oil pan gasket.Thank you