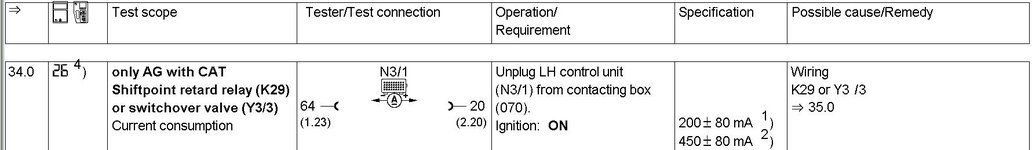

When pulling codes today, I got a dtc 26 on socket 19 (the Diagnostic Module). I also got a dtc 6 (Idle Speed Control inop.) but I'm not sure the two are related. Occasionally I get ETA issues when it freezes at night. Maybe the upshift delay problem has been there for some time but only manifests itself when it freezes.

Is the upshift delay the device on the left side of the transmission that has the hose running to the intake manifold? I'm thinking that as long as no transmission fluid is getting sucked into the intake on hard right turns, I don't really care if the car is held in low gear when it's cold. In fact, it is more of a nuisance when it works correctly.

Is the upshift delay the device on the left side of the transmission that has the hose running to the intake manifold? I'm thinking that as long as no transmission fluid is getting sucked into the intake on hard right turns, I don't really care if the car is held in low gear when it's cold. In fact, it is more of a nuisance when it works correctly.

Replacing the rubber elbow with one from my stash (remembering the extra 124 elbows I had from replacing them at the ACC vacuum distribution point behind the passenger side airbag) it was a 30-second operation to replace the elbow and re-attach the Mityvac.

Replacing the rubber elbow with one from my stash (remembering the extra 124 elbows I had from replacing them at the ACC vacuum distribution point behind the passenger side airbag) it was a 30-second operation to replace the elbow and re-attach the Mityvac.