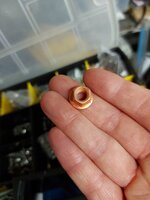

I've searched high and low - does anyone have any tips on removal the downpipe and the crossover pipe? Let me explain. I decided to fix what ain't broke, so I decided to change the O2 sensor. I soaked it in Kroil / PB blaster for two weeks (ModeratelyPaced Jack for the win BTW). Anyways, this O2 sensor is original. After 30 years of living attached to this bung, it ain't moving. I cannot get enough leverage with the scant amount of room above the O2 sensor bung / below the floor of the car to get any serious leverage on the O2 sensor socket.

So I decided --- well, I might as well drop the downpipe assembly to get at the O2 sensor where I can get a lot more leverage out in the open.

But then I thought - heck, I have a Flieben downpipe, crossover pipe, and catalytic converter on the shelf. If I'm gonna fuss with doing all that, I might as well just replace all that that jazz.

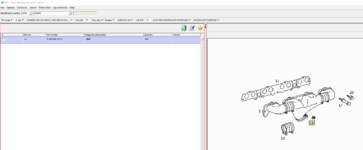

First, my lower crossover connection looks pretty crusty. Diagram for reference. My lower crossover connection is the circled one. Those nuts look like I'll probably be hitting them with an air chisel or something? @kegmankipp suggests a sawzall (or in @RicardoD's case a Milwaukee Hackzall) but I dunno, I mean an air chisel can probably split the nut.

@sheward's crossover pipe lower connection below <--- I am majorly jealous of this.

Anyways I am not too worried about the lower circled connection. I am worried about the UPPER connections, the ones indicated by the red square.

So far I have found - always use a 6 point socket of the proper size - and I have also found that @gsxr has "never had a problem" with the UPPER connections. I also found that @gerryvz recently dropped his crossover pipe (his pics below) --- but his crossover pipe was relatively smooth sailing.

What I would like to avoid is this experience by @hnyc, where, and I quote:

Anyways, thoughts appreciated. I'm not even sure I can hit those upper crossover / downpipe bolts with PB blaster from below, the are so far up there!

So I decided --- well, I might as well drop the downpipe assembly to get at the O2 sensor where I can get a lot more leverage out in the open.

But then I thought - heck, I have a Flieben downpipe, crossover pipe, and catalytic converter on the shelf. If I'm gonna fuss with doing all that, I might as well just replace all that that jazz.

First, my lower crossover connection looks pretty crusty. Diagram for reference. My lower crossover connection is the circled one. Those nuts look like I'll probably be hitting them with an air chisel or something? @kegmankipp suggests a sawzall (or in @RicardoD's case a Milwaukee Hackzall) but I dunno, I mean an air chisel can probably split the nut.

@sheward's crossover pipe lower connection below <--- I am majorly jealous of this.

Anyways I am not too worried about the lower circled connection. I am worried about the UPPER connections, the ones indicated by the red square.

So far I have found - always use a 6 point socket of the proper size - and I have also found that @gsxr has "never had a problem" with the UPPER connections. I also found that @gerryvz recently dropped his crossover pipe (his pics below) --- but his crossover pipe was relatively smooth sailing.

What I would like to avoid is this experience by @hnyc, where, and I quote:

That’s how this whole thing started.

I snapped off a crossover pipe bolt in the d/s manifold end. So the manifold had to come out.

Anyways, thoughts appreciated. I'm not even sure I can hit those upper crossover / downpipe bolts with PB blaster from below, the are so far up there!