The old AMPS phone control buttons represent a wasted opportunity. So many glorious buttons up there on the ceiling, flashing indicator lights, and a microphone --- all wasted because AMPS analog phone service no longer exists. I decided to do something about it.

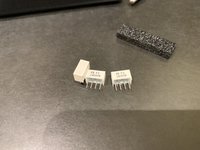

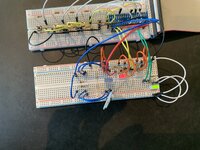

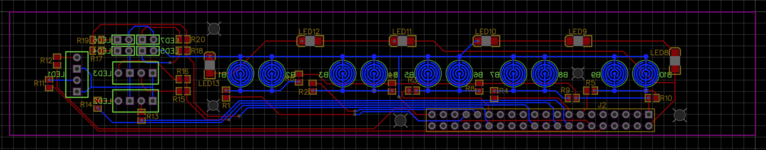

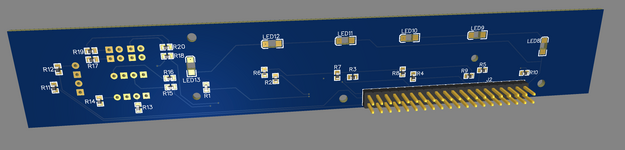

I consulted with @darek_u who has modified the original control board and soldered button contacts to a commercially available bluetooth handsfree device and garage door opener. The original circuit board is below:

I decided to rule out just repurposing the buttons / microphone and soldering the ceiling button contacts to some commercially available bluetooth hands free device. The reason why I ruled this out was because:

[EDIT - I am editing the button states / LED states below as I write the code and find corner cases]

I consulted with @darek_u who has modified the original control board and soldered button contacts to a commercially available bluetooth handsfree device and garage door opener. The original circuit board is below:

I decided to rule out just repurposing the buttons / microphone and soldering the ceiling button contacts to some commercially available bluetooth hands free device. The reason why I ruled this out was because:

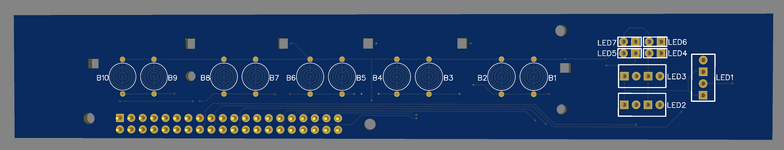

- I wanted to use ALL the Mercedes ceiling buttons, not be constrained with the buttons that a commercially available HF device gave me.

- I wanted to control the indicator lights in the ceiling button panel --- I wanted maximum use of the ceiling panel.

[EDIT - I am editing the button states / LED states below as I write the code and find corner cases]

- SEND Button -> Accept call

- M1 Button -> Decrease Volume

- M2 Button -> Increase Volume

- D Button -> Short Press = Cycle through Connect / Disconnect the currently paired BT device. BT devices are sometimes finicky and aren't always connected when you expect them to be. So, I will use the button to give the user the option force a connection if need be, without having to powercycle the thing. I anticipate this function to be seldom used. Long Press = Pair New Device

- END Button -> Short Press = Hangup call. Long Press = Power Down.

- Dot -> Solid Green - signifies power on / power off

- "In Use" -> Solid Blue - A BT device has been paired and connected.

- "In Use" -> Flashing Blue - The unit has entered pairing mode

- "Roam" -> Solid Yellow - A BT device has been paired but is currently NOT connected. This might happen if you forgot to bring your phone with you in the car, or if you have bluetooth on your phone turned off.

- "No Svc" -> Solid Red - No BT device has been paired.

Last edited: