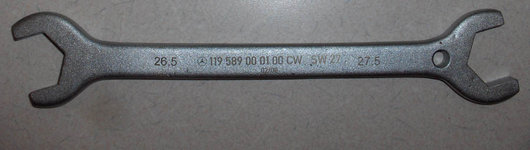

Wow 30 dollars 10 years ago. More than triple on some websites now!

So I figured what was up with me being unable to rotate the crankshaft. Its a very simple thing but n case someone read this a few years from now I'll be clear.

The 6mm (M6) bolts that I used were pinned in the rear of all 4 cams. I was looking at the right (passenger in USA) side m6 bolts and I could see that they were stucxk and needed the crank to rotate clockwise just a mm so that I could wiggle them out. I assumed the left side bolts needed the same. I later realized that the left side cams needed the to be rotated a mm ANTI- clockwise (wrong way of rotation of engine) and that the more I kept trying to turn the crankshaft bolt clockwise (the correct way) the more the M6 bolts in the back of the cams were getting more wedged. I am lucky I checked this before applying more force because I could have broken the cam bearing which the m6 bolts pass through.

So as always, keep checking and making sure of things. Assuming leads to damage or doing the job again. Also

rarely is the solution to apply more force!!

So anybody doing a search online and seeing this a few years or months from now please understand that I am not writing a step by step detailed set of instructions. I am just hoping to help you learn or avoid things that got me frustrated.

- My car is a 1995 E420 with m119.

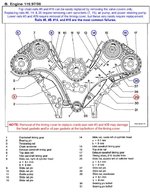

When you attempt the job of replacing your three UPPER timing guides add these fun facts to whatever instructions you are following:

The left side power steering bracket can be removed from the engine block without removing the power steering pump itself from the bracket to save time. So there are two 13mm bolts at the rear (one is at the top, just under the cylinder head near the edge. If you put ur hand near the AC hose on the side of the engine and feel in the are described you will feel a 13mm bolt there. The second bolt is very hard to see as there is the AC compressor and pipes blocking the view but it is a 13mm that has a small metal bracket attached with it that hold a wire. This bolt is the difficult one to remove if you never remove the AC compressor. I had to replace my compressor anyway so I had more space to see and take it off. The bolt is kind of just above the compressor, so if you can put your hand or use a small mirror you should see/feel it. ). The third bolt holding the power steering is a 6mm allen bolt that is from the front of the bracket, look to the left side of the PS reservoir, down a bit and you will see a 6mm allen slightly hidden there, maybe use a flashlight to see better.

- Accessing the upper timing guide pins for the guide nearest the left (drivers) exhaust cam means you need to move the PS bracket, but I did not have to disconnect it at all or empty the PS fluid in the reservoir). I simply move the pump as far as I could safely out of the way to just about fit the pin removal tool, or bolts/washers/socket onto the pins. For one of those pins I had to move PS pump far to the left, the other one I moved it far to the right.

- Never ever wiggle the cam tool or the bolt you are using when it is screwed into the pin!!! I snapped the tool like this! When you for example put the pin in a bit but u don’t feel that it is aligned so you try to pull it out, but its stuck, do NOT wiggle it. Either grab the protruding pin with a cloth and pliers (to not scratch/damage) or try and use the tool/bolt to continue drawing it out.

- Removal of the Cams: Pin the cams. MARK the CAMS and the CHAIN together with a marker pen or something suitable. Take pictures! Naturally after pinning the cams with your 6mm bolt wit the crankshaft at 45 deg BTDC or close to that point to allow the pinning to occur (mine was at 40 deg BTDC) you remove the tensioner which is held in by one 13mm bolt and a 13mm nut as well, don’t worry when you remove it the tensioner will not fly out at you or anything. You start undoing the bolts that hold down the cams. Start from the CENTER bolts and gradually work your way either side of the center. But you only start GENTLY cracking the bolts loose. Yes it will seem a bit tedious but you MUST gradually release the pressure that is being exerted on the cam, do not just take the bolts off at one time you can crack the cam! It will only take you like 10 mins or less anyway and this method means you DO NOT need to remove those cam adjusters that are a bloody nightmare to re-install unless you have the special socket tool that is sold. So remove the right exhaust cam then remove the right intake cam. Of course at this pint the chain will be dangling down, you can tie a plastic zip tie or anything suitable to hold the chain up. You can now after removing things in the way, start pulling the pins holding the upper right timing guide. You do NOT need to remove the oil dipstick from the engine, just undo the bolt holding it and lift it a bit and move it to the side slightly to necessary. So you do this guide rail but my advice is do NOT bother trying to reinstall the cams yet, just put them with their respective bearings and bolts in a clean area while you do the rest of the guides.

Left side guides, once the PS pump is moved you will see the pins clearly for both guides and it is self explanatory. Of course again remove the cams in the same way as before, gently. I am not certain if the guide can actually fall down inside the engine but maybe have a finger on it when you remove the last pin. The pins are NOT the same thickness, one is 8.1mm and other is 9mm. Take note when you remove each pin, write ‘top’ or ‘bottom’ on them so that you do not doubt which one was where.

There are two upper guide rails that are the same part number, the wider part at goes at the top, as Dave said before it is probably impossible to fit it upside down anyway.

Install cams: Once you have replaced the guides you install the cams starting with the left exhaust cam as it was the last one you removed. You DO NOT start bolting it into place fully until you have managed to install at least 3 cams and pinned them again. It takes a bit of time to do this but you need to understand that you are trying to line up the chain exactly as you had it before but the cams are in different positions trying to push down on the lifters and so the cams will not just sit freely. SO I would get the cam to line up with the marking on the chain (marker or whatever you marked) then gently start installing the cam bearings and bolts as appropriate to try and get the cam to get into its proper position. I did this for all 3 cams. I made sure they were all pined and the mark on the chain and cam all lined up as before you started removing them. Then the last cam goes in pretty easily and lines up and pins easily.

Once the cams are bolted in and you triple check the chain is in the correct pre-removal position in relation to all 4 cams, you can reinstall your tensioner. It just bolts in, no adjustment or whatever, torque was 25nm I think. Cam bearing bolt were not high torque at all, maybe 8 or 9nm.

I used Permatex 51531 blue anaerobic sealant for upper timing covers and those 3 air pump bolts.

Use a Genuine Mercedes gasket set for the valve covers, fits superbly. Get it online.

That’s all I can remember now, got to get back to work now…