Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve timing - Camshaft jumped 1 tooth! (1995 SL500)

- Thread starter 73eldorado

- Start date

I like the idea of trying to narrow it down. Is it possible to rotate each cam separately? It sounds like it should be possible once the cams are pinned at 45 degrees. Remove the tensioner then remove right side exhaust cam sprocket lift the chain take out that pin and rotate that cam shaft 360 degrees then pin it and move on the the intake cam. Is this possible without doing damage to the valves? If this is possible how much tension should I expect once the cam is unpinned and the chain is off?

Rotating the cams separately is not easy to do. I would focus on the sprockets. Maybe the sound was there before you changed rails but it was probably not there before the right rail was damaged. You can easily check the four cam sprockets for bent theeth. with our endoscope coming up, you will be able to look at the guiding sprocket in the center. I would assume that either a cam or the center sprocket is damaged. The crank sprocket turns faster, it cannot be the cause.

Yes. Pin the cams at 45°, then DO NOT rotate the crank, and you can rotate each camshaft separately. It's not easy to rotate the cams as they are under pressure from the valve springs. You'll need to get creative to rotate each smoothly / completely. If one is the cause of the noise, it will feel very different than the other cam. You can rotate the cams in either direction with the chain off.I like the idea of trying to narrow it down. Is it possible to rotate each cam separately? It sounds like it should be possible once the cams are pinned at 45 degrees. Remove the tensioner then remove right side exhaust cam sprocket lift the chain take out that pin and rotate that cam shaft 360 degrees then pin it and move on the the intake cam.

Well, it won't cause any more damage than may already have occured...Is this possible without doing damage to the valves?

As soon as the cam is unpinned with chain off, it will "jump" to a point of least resistance. You'll want to have a wrench on the cam to allow it to slowly move, and then keep rotating slowly.If this is possible how much tension should I expect once the cam is unpinned and the chain is off?

The noise is not from the center idler sprocket, as it exactly follows 1 cam rotation, which is not the same as the center sprocket (different diameters).

Yep, when you loosen each cam (remove the sprocket/chain) you will want to be holding that cam so that it doesn't "sproing" in one direction or the other, as it will do until it finds a place where it is under less tension. You will want to have a large wrench on the flat portion of the cam to hold it. Make sure that all of the other three cams are pinned when you are doing this, and as the @gsxr said, DO NOT rotate the crank.

Despite the @JC220 warning me about it, I experienced the "sproing" effect when I removed the chain from the sprocket, and it rotated about a 1/8-1/4 turn quite suddenly under spring pressure. Won't hurt anything, but it's startling !! You have to have the large wrench to rotate the cam back to where it needs to be, so you can pin it and move onto the next one.

Once the cam is loosened, you should rotate it and listen for any noise and feel for any interference.

I do not believe your issue is with any of the cams and valves.

I believe it is more with the chain/chain path/rails and/or intake cam adjusters.

But, unpinning and rotating each cam will help eliminate (or pinpoint) the cams/valves as an issue or cause of the resistance/noise.

Despite the @JC220 warning me about it, I experienced the "sproing" effect when I removed the chain from the sprocket, and it rotated about a 1/8-1/4 turn quite suddenly under spring pressure. Won't hurt anything, but it's startling !! You have to have the large wrench to rotate the cam back to where it needs to be, so you can pin it and move onto the next one.

Once the cam is loosened, you should rotate it and listen for any noise and feel for any interference.

I do not believe your issue is with any of the cams and valves.

I believe it is more with the chain/chain path/rails and/or intake cam adjusters.

But, unpinning and rotating each cam will help eliminate (or pinpoint) the cams/valves as an issue or cause of the resistance/noise.

I don't think it's the intake adjuster, because that is in a fixed position without oil pressure. And when then noise occurs, there is no change in position between the adjuster/sprocket, and camshaft (at least on the bank visible in the video).

It would REALLY help if the noise could be located... left? right? top of engine? front of engine behind timing cover? Etc.

It would REALLY help if the noise could be located... left? right? top of engine? front of engine behind timing cover? Etc.

Once again, thanks to all for your advise. This forum is a wonderful resource. I will report back when I have an update.

James

James

Update. Endoscope arrived yesterday. I have attached a photo of each cylinder. I think I see a problem. Number 4 (firewall passenger) looks different than the others. I had a low end scope when I had a look the first time and either didn't check this cylinder or didn't see the damage. This project has now exceded my expertise and will need to go to a shop. Now what I need to decide is whether to source another motor or fix this one.

Attachments

Hi,

I am sorry but you will at least need a new piston and you have to have a closer look at the head of that cylinder. Something from the head is hitting the piston - surprising sound for that to me. If the cylinder itself is undamaged, it may work out with a good used piston and another used head. If that is not possible, I would look for a good used engine.

First of all, get that head removed.

Good luck!

I am sorry but you will at least need a new piston and you have to have a closer look at the head of that cylinder. Something from the head is hitting the piston - surprising sound for that to me. If the cylinder itself is undamaged, it may work out with a good used piston and another used head. If that is not possible, I would look for a good used engine.

First of all, get that head removed.

Good luck!

I have a cam wrench on order and will try to isolate the interference when it arrives. In the mean time here are a few more photos of the damaged piston. They are the best quality I can get with this scope. My first conversation about this with a long time MB mechanic suggested finding a good used engine as the best way to go. He said this one would be worth repairing only if we knew if the cylinder walls were undamaged. I'm not sure if I'm up for the task of pulling the cylinder head.

Attachments

If I ask Santa for a used m119 for Christmas what engine numbers will be compatible. My engine is a 5.0 119.972, would a 4.2 119.975 be compatible?

You need another M119.972 engine from a 1993, 1994 or 1995 R129 SL500, which is a direct bolt-in.

Sure, a 4.2 liter engine would work, but why would you devalue your car with a smaller displacement motor? You would have some messing around with the computer modules as well.

SL500 engines are not that hard to come by. They made many more of them than .974s for the E500E. Just be diligent in your search and use parts search engines. EBay and other sources.

Folks here can and will help you to do this, or point you in the right direction. A good used engine shouldn’t be more than the $1,500 range TOPS, likely much less.

Sure, a 4.2 liter engine would work, but why would you devalue your car with a smaller displacement motor? You would have some messing around with the computer modules as well.

SL500 engines are not that hard to come by. They made many more of them than .974s for the E500E. Just be diligent in your search and use parts search engines. EBay and other sources.

Folks here can and will help you to do this, or point you in the right direction. A good used engine shouldn’t be more than the $1,500 range TOPS, likely much less.

Thank you, I agree a 5.0 is the way to go. I will start my search next week and see what is available in my area (Vancouver).

Try car-part.com to search for engines. You may find some nearby. Get the VIN of the donor and look up the datacard to verify it's a .972 engine, and you can also pull an AutoCheck/Carfax report to estimate miles on the engine, as some yards may not report this accurately, if at all. At least look through the oil fill hole to make sure there isn't sludge or other nasty stuff; if you can look at the engine in person before buying, pull one or both valve covers. And make sure it rotates smoothly by hand. If you are lucky the salvage yard will have done a compression test before pulling the engine.

Plan on a complete re-seal before installing, particularly the front crank seal. And new plastic chain rail guides... maybe metal oil tubes... the list goes on.

Plan on a complete re-seal before installing, particularly the front crank seal. And new plastic chain rail guides... maybe metal oil tubes... the list goes on.

By the way, I think it would be interesting to do a tear-down and post-mortem on this engine, once you obtain a new one.I have a cam wrench on order and will try to isolate the interference when it arrives. In the mean time here are a few more photos of the damaged piston. They are the best quality I can get with this scope. My first conversation about this with a long time MB mechanic suggested finding a good used engine as the best way to go. He said this one would be worth repairing only if we knew if the cylinder walls were undamaged. I'm not sure if I'm up for the task of pulling the cylinder head.

It looks pretty strongly to me like the piston damage shown in the bore-scope photographs is the result of pre-ignition or pretty severe detonation. Of course, a number of different factors could cause detonation, including a plugged injector in that cylinder; a leaned-out mixture; or perhaps low fuel pressure.

A dead giveaway that your problem was caused by detonation is that the damage that occurred on the edge of the piston.

I'd take that with a pinch of salt! After all they are selling the engine.... I'd confrim for myself if possible and definitely absolutely ask for borescope photos of every cylinder before paying.

When buying engines off ebay etc some sellers will accommodate I have had this done before. Ideally though inspect yourself in person.

When I bought a used M119 a while back I removed both valve covers and scoped all cylinders. This told me more than an arbitrary compression test.

Plus more often than not when a car comes into a lot they drain all fluids. So - if you ask them for a compression test do you think they will first fill the sump with oil then spin it on the starter? Nope. They will spin it to get results. Whereas borescope requires turning by hand only.

Update. With the help of my mechanic we were able to source (from someone he has used before and trusted) a motor with 50,000 miles. I had seen engines with 90,000 miles ranging from $1000 to $1500 plus freight and duty to my door. I was very happy to find something local with low miles from someone my mechanic knew and decided to pay the higher price. At the end of the day the engine was $2200 and the swap should happen next week. Pricing is probably on the high side but at least we have something that should last for a while. It was hard to justify as these R129s are not worth that much money. However the car is in great condition and lot of fun to drive. Thanks to everyone for your help. I learned a lot about my car and had fun working on it.

Attachments

Nice to hear you scored a good low-mile engine. Keep in mind that just because it's low miles, doesn't mean it needs nothing... the list I started back in post #70 above still applies. All the work is easier and fewer hours labor with the engine out of the car. You may be able to swap over good / recent parts from your old engine.

I am definitely going to take your advice and replace the crank seals and all the upper timing chain guides as well as the tensioner. Oil pickup and oil level sensor will be replaced as well.

Update. Happy to say I got the car back a few weeks ago and it is running strong. It did put up a fight though. After the engine swap the ASR light was coming on and it would go into limp mode. This had happened to me on the rare occasion prior to the engine issue but it would always clear itself after shutting it off and restarting. It turns out that the throttle actuator harness was crumbling and i think it got disturbed with the engine and intake swap and it finally failed. Thanks again to this site I got in touch with Don Roden (great guy) and he sent out a rebuilt unit that is working nicely. The only issue now is the ABS and ASR lights are always on. The system is not showing any codes and it doesn't go into limp mode. I am thinking of picking up a new brake light switch with my next parts order to see if that does anything. I have tried to read as many threads as I can on this but I haven't found one with my particular problem. If anyone has any ideas please let me know.

You mean the ABS+ASR lights are always on, but the car is NOT in limp mode?The only issue now is the ABS and ASR lights are always on. The system is not showing any codes and it doesn't go into limp mode. I am thinking of picking up a new brake light switch with my next parts order to see if that does anything. I have tried to read as many threads as I can on this but I haven't found one with my particular problem. If anyone has any ideas please let me know.

Are the ABS and ASR not working? If not... sounds like either a bad ASR module, or lack of power to the ASR module.

Fault codes from the ASR module would be helpful.

Yes, correct ABS+ASR lights are alway on with not codes and no limp mode. The car drives just like it did before except those two lights are always on. I am quoting my mechanic regarding codes. How does one isolate codes from the ASR module? If there is a thread regarding this please let me know.

ABS+ASR fault codes can be pulled from pin 6 of the 38-pin diagnostic socket, using a hand-held blink code reader.

You can test if ABS is working by stomping on the brakes at low speed on dirt, or dirty/wet pavement, and see if tires lock up. And you can test ASR by trying to purposely spin a tire. I would assume neither system is working if both fault lights are on.

Check the blade-style fuses in the BM/GM. Fuse #1 supplies the ABS/ASR module. Screenshot below is for a W124, the R129 layout will be different but shares the same BM/GM and fuse.

You can test if ABS is working by stomping on the brakes at low speed on dirt, or dirty/wet pavement, and see if tires lock up. And you can test ASR by trying to purposely spin a tire. I would assume neither system is working if both fault lights are on.

Check the blade-style fuses in the BM/GM. Fuse #1 supplies the ABS/ASR module. Screenshot below is for a W124, the R129 layout will be different but shares the same BM/GM and fuse.

Thanks for getting me started on the diagnostics. I will report back with the results.

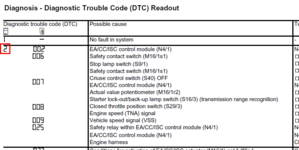

Checked socket 6 and no codes. Socket 7 however shows two codes, 3 which is Cruise control/idle speed control actuator and 11 which is fuel safety shut-off to LH-SFI control module. Checked all fuses in the BM/GM and they are good. I still need to find a slippery place to test the abs and asr.

New brake light switch installed and no change. ABS+ASR lights are still on. I have disconnected the battery and will put it on a charge over night. It tested at 12.45 volts after my last short ride. The battery disconnect has helped me with electrical gremlins in the past.

The lights are on right from start up and never go off. I need to press the brake pedal when I start the car which is a safety feature. I don't know if that counts as using the brakes. I will re-test for codes tomorrow and see if anything has changed.

Thought I would post a quick update. I have replaced the brake light switch but the lights are still on . I did find some loose gravel and I could spin the tires quite easily. I think that tells me that feature is not working. My guess is the ABS is not functioning as well. I'm okay with no traction control but ABS would be nice. On a side note and the reason this post was delayed, while I was out test driving the car I noticed reverse gear was slow to engage. It had always been a bit slow but now it was quite noticeable. A few days later I lost reverse all together. This car is truly testing my love for it. The short story is I now have a rebuilt transmission. Back to the ABS/ASR, I cleared the codes and drove for a few days and today I rechecked the codes to find pin#6/30 (ASR only CAN date bus to EA/CC/ISC control module interrupted) and pin#7/2 (cruise control/idle speed control). From reading other posts these two codes seem to come up at the same time. Right now I don't mind having the ABS and ASR lights on all the time as long as the car is working but I know that's not going to last and I will have to find the issue. If anyone has had experience with these codes I would appreciate the feed back.

Well it sounds like you are halfway to the 10K minimum first year ownership of a new E500E with the trans rebuild.

not necessarily going to turn off the lights, but have you used a pressure bleeder to change out the brake fluid since you have owned the car, and also bled out the ABS pump? It should be changed every 18k-24k miles depending on use. Just saying to work off a known quantity. My car had some serious old fluid in the hopper....

not necessarily going to turn off the lights, but have you used a pressure bleeder to change out the brake fluid since you have owned the car, and also bled out the ABS pump? It should be changed every 18k-24k miles depending on use. Just saying to work off a known quantity. My car had some serious old fluid in the hopper....

See previous posts #78 and #80 above.I did find some loose gravel and I could spin the tires quite easily. I think that tells me that feature is not working. My guess is the ABS is not functioning as well. I'm okay with no traction control but ABS would be nice. I cleared the codes and drove for a few days and today I rechecked the codes to find pin#6/30 (ASR only CAN date bus to EA/CC/ISC control module interrupted) and pin#7/2 (cruise control/idle speed control). From reading other posts these two codes seem to come up at the same time. Right now I don't mind having the ABS and ASR lights on all the time as long as the car is working but I know that's not going to last and I will have to find the issue. If anyone has had experience with these codes I would appreciate the feed back.

Other than swapping modules for testing (specifically, the E-GAS module, ASR module and BM/BM module)... to get a more specific diagnosis you would need a digital scanner to find out which exact fault is being shown by blink code #2. There are six potential sub-codes which you can only access with a digital scanner.

Thanks Dave, I will be going in for my postengine install 1000 km check next week and will bring this up with my mechanic.

Hopefully this is my last update on this thread. I was out of town for the summer and came back with renewed energy to resolve my ASR/ABS lights on no limp mode problem. I decided to purchase a used E Gas module and ASR module. While researching part number compatibility I came across a thread on this site were Gerry was telling a member to make sure all modules had clean connectors and were seated properly before running out and buying different ones. Well I thought I would humour him and did just that not thinking for one second It would do anything. I pulled each module used contact cleaner then tapped them in to place with a rubber hammer. I had to wait until this morning to fire it up and when I did the DANG lights did not come on. I still need to pull the codes but right now I am very happy. Thanks again for all the great info on this forum.

Similar threads

- Replies

- 6

- Views

- 272

- Replies

- 7

- Views

- 219

- Replies

- 12

- Views

- 172

- Replies

- 13

- Views

- 395

Similar threads

- Replies

- 6

- Views

- 272

- Replies

- 13

- Views

- 395