@500AMM: Keep in mind the dual auxiliary fans were never intended for primary cooling. These fans have 2 functions, when used with the mechanical/viscous clutch:@friendlymbtech, does this single fan installation make the dual auxilliary fans redundant?

1) At low fan speed (through the resistor behind the headlight), the twin fans provide additional airflow at low vehicle speed / low engine RPM, i.e. when sitting in traffic. This is meant to aid in AC performance, it isn't meant to cool the engine. The low speed triggers based on refrigerant pressure - turns on at 16 bar, off at 12 bar (232 psi on, 174 psi off). Low speed won't trigger at all, ever, based on engine/coolant temp. The fans make a large, rapid change in refrigerant pressure when they cycle on/off. On a warm day with AC running, connect manifold gauges and watch the high side pressure as the fans cycle. This video shows the gauges and if you listen closely, you can hear when the fans are turning on/off... unfortunately there was some annoying wind noise (sorry).

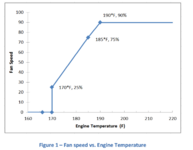

2) At high fan speed, the the twin fans trigger at 107°C coolant temp, based on a signal from the 2-pin temp sensor to the HVAC control unit, which trigger the high speed fan relay. The fans will turn off at something like 98°C coolant temp. This is to aid engine cooling (not AC performance), once again at low vehicle speed / low engine RPM. At higher speeds/RPM, the viscous clutch is supposed to move enough air to keep things cool, or at least keep the engine below 107°C. With a good fan clutch (engaging correctly), it's abnormal for engine temps to reach 107°C when the cooling system is all in top shape.

So, in light of the above, Arnt... the single fan installation DOES make the dual auxiliary fans redundant, as long as the single fan can receive a signal from the AC system to run the fan at a low speed when refrigerant pressure is high enough. This should be possible if the controller has an auxiliary input, which could be wired to the factory red refrigerant pressure switch at the receiver/drier. (Note - both the controller friendlymbtech used, and the controller Jlaa plans to use, have an AC input to run the fan with air conditioning.)

In theory you could sort of skip this AC-triggered function if the single fan runs at low coolant temp, but I personally would want the single fan to be completely off until engine coolant temp exceeds 90-95C or so, then have the fan speed ramp up proportionally with coolant temp. The nice thing here is each person can dial in the temp settings to their personal preference.

The downside here is that there's a slight possibility of high refrigerant pressures with low coolant temp, where the single fan may not run at all. Also, with only a single fan, there is no redundant cooling backup. The twin fans don't weigh much and shouldn't restrict airflow, so I'd be tempted to leave them installed as a backup in case something goes awry with the single/primary fan.