We know dimensions on the 204/600W unit. I don't think we have dimensions for the 850W fan (212-906-10-02), and don't know if there may be fitment issues. Note the controller/electronics is a separate box on the 850W fan, not integrated with the center motor assembly - this could preset packaging issues?

In this case it isn't likely that the larger one will be "better". The main improvement with the OE fan and PWM speed control should be from improved airflow at low speed / low RPM, along with the ability to not run the fan at all when engine temp is below your setpoint. The fans should almost never need to run at maximum speed, or anywhere near max speed. If the larger unit fits no problem, great... but if not, I'd stick with something that will have minimum installation headaches.

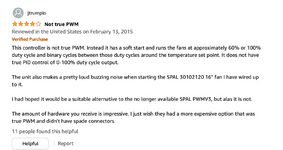

Photos attached below of the 850W unit for reference.

Hang on a minute ! Is this mod about not having a loud intrusive fan or is it for better cooling??

Hang on a minute ! Is this mod about not having a loud intrusive fan or is it for better cooling??

Christian,

Christian,