Hello everyone!

Edit: 24.09.2022

SPREADSHEET with parts replaced HERE

I think it's time to make my own owner's thread on this forum to help others and maybe bring something new when I'm in a middle of preparing this car for full respray hopefully next year.

This 400E Sportline is in my hands from 2014. It is my first and I hope the last car that I will own.

Car details and options:

A lot have been done to this car in past 8 years, mostly mechanical repairs and some rust protection.

This is how this car looked like last year.

And this is how it looks like now.

I will be adding more pictures in the future as this job goes along. Right now I'm at the point of preparing for storage of the body for a winter, sadly I don't have garage this big to do any work on it, but engine and transmission is already there and this is what I will be preparing over the winter. Along with sand blasting, zinc plating and AC rebuild as I found out metal shavings in compressor oil. This is because AC dryer was not replaced even once for the whole life of a car.

Now for a jobs that where performed in past 8 years that I have picutres of.

Wood polishing on a budget, it turned out really well, but wood cracks remained of course.

Before:

After:

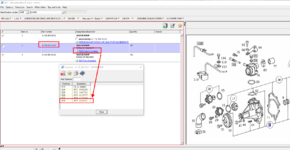

Powersteering pump rebuild:

New front OEM struts, one of them leaked after only 1k km, that's what you get sometimes when buying parts from ebay for half the price of new ones at the deeler. (MB didn't had front struts when I was performing this job, they appered two weeks later...) After that I bought standard Sachs 115 070.

Engine lower, upper and AC warring harness repair. I'm still wondering how this cars even run with warring like that.

Timing chain, guides and water pump replaced. I bought Hella water pump because OEM pump with number 119-201-07-01 is NLA!!! and so it's Hella and INA right now. In Europe I don't have access to GRAF water pump. New hella pump is junk, my engine temps raised about 10 degrees after this job and front pulley wobbles like crazy, but I got no other option.

Guides didn't looked bad for almost 280k km but there was almost 5 degrees of timing missaligment on the crank.

That's it for now at the end of this post I would like to thank you for shearing your knowledge so I could perform a lot of repairs and diagnostics by myself with yours help.

Edit: 24.09.2022

SPREADSHEET with parts replaced HERE

I think it's time to make my own owner's thread on this forum to help others and maybe bring something new when I'm in a middle of preparing this car for full respray hopefully next year.

This 400E Sportline is in my hands from 2014. It is my first and I hope the last car that I will own.

Car details and options:

- production 1993

- 199 - paint

- 240 - outside temperature indicator

- 244 - front sport seats

- 249 - rearview auto dimming mirror

- 278A - gray leather

- 281 - sport steering and leather shift knob

- 341 - additional side markers in fenders

- 412 - sunroof (sidenote - I hate this thing)

- 441 - electric steering column

- 471 - ASR

- 538 - automatic antenna

- 540 - rear roller blind

- 543 - curtains with illuminated mirrors

- 570 - front folding armrest

- 580 - AC

- 592 - athermic windows, rear laminated glass

- 611 - door lights

- 620 - EGR

- 630 - warning triangle

- 653 - sport suspension, 8-hole alloy wheels 16'

- 812 - rear speakers

- 823 - additional equipment for Switzerland

- 855 - I don't know what that means

- 864 - same

- 873 - heated front seats

- 880 - IR door lock

- 953 - Sportline

A lot have been done to this car in past 8 years, mostly mechanical repairs and some rust protection.

This is how this car looked like last year.

And this is how it looks like now.

I will be adding more pictures in the future as this job goes along. Right now I'm at the point of preparing for storage of the body for a winter, sadly I don't have garage this big to do any work on it, but engine and transmission is already there and this is what I will be preparing over the winter. Along with sand blasting, zinc plating and AC rebuild as I found out metal shavings in compressor oil. This is because AC dryer was not replaced even once for the whole life of a car.

Now for a jobs that where performed in past 8 years that I have picutres of.

Wood polishing on a budget, it turned out really well, but wood cracks remained of course.

Before:

After:

Powersteering pump rebuild:

New front OEM struts, one of them leaked after only 1k km, that's what you get sometimes when buying parts from ebay for half the price of new ones at the deeler. (MB didn't had front struts when I was performing this job, they appered two weeks later...) After that I bought standard Sachs 115 070.

Engine lower, upper and AC warring harness repair. I'm still wondering how this cars even run with warring like that.

Timing chain, guides and water pump replaced. I bought Hella water pump because OEM pump with number 119-201-07-01 is NLA!!! and so it's Hella and INA right now. In Europe I don't have access to GRAF water pump. New hella pump is junk, my engine temps raised about 10 degrees after this job and front pulley wobbles like crazy, but I got no other option.

Guides didn't looked bad for almost 280k km but there was almost 5 degrees of timing missaligment on the crank.

That's it for now at the end of this post I would like to thank you for shearing your knowledge so I could perform a lot of repairs and diagnostics by myself with yours help.

Last edited:

Just kidding or maybe not LOL.

Just kidding or maybe not LOL.

) and zinc plate remaining bolts from oil pans and any remaining that I missed. They estimate 8 day shipping to Poland so not much of a halt.

) and zinc plate remaining bolts from oil pans and any remaining that I missed. They estimate 8 day shipping to Poland so not much of a halt.