Hello everyone! I'm adding heated seats to 1994 E320. The heating elements are going to be from another chassis.

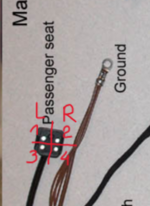

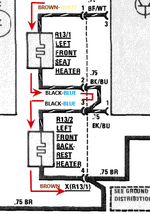

Therefore, I need to find out the distribution (bottom/back & +/-) of the mother plug-in cable. I have marked each of them in the attached below screenshots.

If you know the wiring distribution in this circuits please share. Thank you so much in advance!

Therefore, I need to find out the distribution (bottom/back & +/-) of the mother plug-in cable. I have marked each of them in the attached below screenshots.

If you know the wiring distribution in this circuits please share. Thank you so much in advance!