This could be controvertial but I do it anyway.

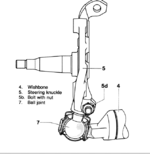

Of four E320's 1994-5 I have, I have to deal with the torn rubber boots of all of them. Remove the tire, and check the rubber boot condition over the ball joint of the lower control arm, most likely, they are torn. Once they are torn, dust can get it and greese can go out. Left unattended, the ball joint can wear badly to have sufficient play. This ball joint design is an unstable design because when it fails, the ball joint pops out and you lose the control of your vehicle.

So, it is important to check the condition of the ball joint of the lower control arm. Uneven tire wear is a sign. Get the tire up and shake it by holding the top and the bottom of the tire. If you have significant play, you probably need a new lower control arm, or replace the ball joint if it is replaceable.

This post is about when you don't have play but the rubber boot is torn. Over at BZ-crasyworlld, they scream: "You must replace the entire lower control arm!!!! No exception!!!!!!!!" by you know who. They claim, once the dust got in, you are dead. You can never get them out and it will wear out INSTANTLY! Wrong! Yes, you cannot get all the dust particles out but as long as it is still tight, not much dust can get under. Clean it up with fresh grease, the wear rate will be minimal, and the lower control arm can still have many years of life left. In fact, once you clean up the old grease, you can see the ball joint is still shining with a mirror finish. If it is rusty and badly scarred, it is time to change,

Today, hardly can you buy good lower control arms anymore. No Lemfoeder. You got those questionable ones. So, between putting in a Febi vs the original with fresh grease and new boot, I chose the latter.

I have done the rubber boots of six ball joints (3 cars and one to go). The ball joint is still tight and no play but the boot is torn. I only replace the boot. I remove the boot, and wipe it clean. Spray some cleaner and wipe it clean and dry again. Then I put in new grease (Mobil synthetic grease) and put in the new boot. It is not an easy job but after doing it several times, I can get one done in about 2 hours at a casual pace. I never rush the job. Take my time as it is the unwound time.

The very first one I did was about four years ago. Just check its condition and the rubber is still good. You can buy this rubber boot, Original MB only, from many on-line vendors. I found RMeuropean has the best price at $11 a piece, but you need to pay a $8.00 flat shipping. Some eBay sellers sell it at $16, free shipping. Of the ones I recently got, it actually says TRW on the boot. The MB tag is on the plastic bag and made in Germany is printed.

jftu105

Of four E320's 1994-5 I have, I have to deal with the torn rubber boots of all of them. Remove the tire, and check the rubber boot condition over the ball joint of the lower control arm, most likely, they are torn. Once they are torn, dust can get it and greese can go out. Left unattended, the ball joint can wear badly to have sufficient play. This ball joint design is an unstable design because when it fails, the ball joint pops out and you lose the control of your vehicle.

So, it is important to check the condition of the ball joint of the lower control arm. Uneven tire wear is a sign. Get the tire up and shake it by holding the top and the bottom of the tire. If you have significant play, you probably need a new lower control arm, or replace the ball joint if it is replaceable.

This post is about when you don't have play but the rubber boot is torn. Over at BZ-crasyworlld, they scream: "You must replace the entire lower control arm!!!! No exception!!!!!!!!" by you know who. They claim, once the dust got in, you are dead. You can never get them out and it will wear out INSTANTLY! Wrong! Yes, you cannot get all the dust particles out but as long as it is still tight, not much dust can get under. Clean it up with fresh grease, the wear rate will be minimal, and the lower control arm can still have many years of life left. In fact, once you clean up the old grease, you can see the ball joint is still shining with a mirror finish. If it is rusty and badly scarred, it is time to change,

Today, hardly can you buy good lower control arms anymore. No Lemfoeder. You got those questionable ones. So, between putting in a Febi vs the original with fresh grease and new boot, I chose the latter.

I have done the rubber boots of six ball joints (3 cars and one to go). The ball joint is still tight and no play but the boot is torn. I only replace the boot. I remove the boot, and wipe it clean. Spray some cleaner and wipe it clean and dry again. Then I put in new grease (Mobil synthetic grease) and put in the new boot. It is not an easy job but after doing it several times, I can get one done in about 2 hours at a casual pace. I never rush the job. Take my time as it is the unwound time.

The very first one I did was about four years ago. Just check its condition and the rubber is still good. You can buy this rubber boot, Original MB only, from many on-line vendors. I found RMeuropean has the best price at $11 a piece, but you need to pay a $8.00 flat shipping. Some eBay sellers sell it at $16, free shipping. Of the ones I recently got, it actually says TRW on the boot. The MB tag is on the plastic bag and made in Germany is printed.

jftu105

Attachments

Last edited: