1992 500E | 169,000 miles | Ran like a top until I took it to a shop.

Okay, everyone, first love the website, and thank you, everyone, for sharing your knowledge. I took my car to a shop here in Seattle that assured me they work on these old Mercedes all the time. Well, they really did a number on my car. Here is what was done at the shop.

-Rebuild transmission from Mercedes and sent from Germany.

-Removed the engine.

-replaced head gaskets

-replaced valve cover gasket

-rear main seal

-pretty much all gaskets were replaced.

-New sparkplug wires and spark plugs (I'm working on taking those our and checking the gap. They said they came pre-gapped from Mercedes but does that mean .8ml? I know it should be 1 or 1.1Ml thanks to you all.) (also, the wires do not seem correct. Not sure what they looked like before, but they all seem too long. They could be aftermarket something. I will check the resistance shortly as I'm waiting for my shop remodel to complete.)

-New steering box

-New bushings

-new timing chain and guides

-Crankshaft seals

-tensioner

Okay, that is how it all started last year, around September. The car ran GREAT before this.

I get the car back from the shop, and it is among down on power by maybe 20 - 25%. (my SL320 is likely fast than it now, and my 600S is certainly faster than my 500E. The car has a slightly rough idle. Like it is missing but not fully missing. The car will die if you give it too much gas too quickly from a start. You have to feather the throttle to keep running. Then it goes but with limited power. Sometimes you can feel the power come on intermittently. Also, the car does not want to shift down often unless you floor it to the click. Even then, sometimes it won't.

I hooked the car up to MB Star, and Some of the diagnostic modules were struggling to read consistently. So I started to replace more stuff. List to follow.

-EGAS Module

-LH Module

-ASR Module

-MAF

-Throttle body

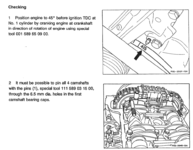

-Crankshaft position sensor (still need to shim it) | Still get this code as well.

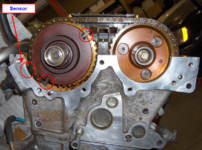

-Camshaft position sensor | Still get this code as well.

-Camshaft magnets

-Fuel injectors

-All breather hoses and vacuum lines. (none detected using the smoke test.)

MB star values. Keeping in mind, I have no idea what some of these values mean, I will share in hopes that you do.

First car runs better cold. Idle is smoother and acceleration seems better

LH1

Oxygen sensor voltage Fluxuates between 172 and 660mV.

The car is running idle at around 661 but will dip to low 600.

On/Off ratio cold sticks to about 50% once warm fluxuates between 35 and 41%

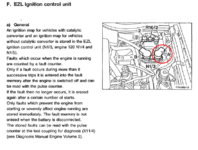

EZ1 (006 Current fault Camshaft PS L5/1) Stored Fault: 006 Camshart Position Sensor) I will frequently also get a Crankshaft.

Ignition angle 17.0 but fluxuates (rough idle) down to 13.4 at times.

tml 30 at 14.6V

Intake manifold pressure 655-670 mbar

No readings for ignition voltage or combustion time/cycl. (my other 500 E gave these readings.

DM I cannot get this module to read easily. Is this normal or an issue? Sometimes it will establish communication but more often then not it won't. I was lucky today.

Current fault 022 camshaft

Stored fault 022 camshaft and 013 camshaft.

Actual values indicates that all sensors are reporting back to the DM.

Absol intake manifold pressure is 370 mbar

I can unplug the camshaft sensor and it makes no difference in how the car idles.

I will look for your replies thank you in advance this has been frustrating. Let me know what your next steps would be. I have considered coil, re-gap spark plugs, checking resistance on plug wires. Ignition module. replace O2's. Perhaps the reading above will tell you guys something that I can't see.

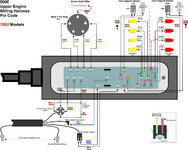

Is there a magnet inside on the camshaft itself the shop could have messed up which gives me the CSP error? My wiring harness appears to be dated 4/2009. I did check the wires and they look new. HELP!

-Matt

Okay, everyone, first love the website, and thank you, everyone, for sharing your knowledge. I took my car to a shop here in Seattle that assured me they work on these old Mercedes all the time. Well, they really did a number on my car. Here is what was done at the shop.

-Rebuild transmission from Mercedes and sent from Germany.

-Removed the engine.

-replaced head gaskets

-replaced valve cover gasket

-rear main seal

-pretty much all gaskets were replaced.

-New sparkplug wires and spark plugs (I'm working on taking those our and checking the gap. They said they came pre-gapped from Mercedes but does that mean .8ml? I know it should be 1 or 1.1Ml thanks to you all.) (also, the wires do not seem correct. Not sure what they looked like before, but they all seem too long. They could be aftermarket something. I will check the resistance shortly as I'm waiting for my shop remodel to complete.)

-New steering box

-New bushings

-new timing chain and guides

-Crankshaft seals

-tensioner

Okay, that is how it all started last year, around September. The car ran GREAT before this.

I get the car back from the shop, and it is among down on power by maybe 20 - 25%. (my SL320 is likely fast than it now, and my 600S is certainly faster than my 500E. The car has a slightly rough idle. Like it is missing but not fully missing. The car will die if you give it too much gas too quickly from a start. You have to feather the throttle to keep running. Then it goes but with limited power. Sometimes you can feel the power come on intermittently. Also, the car does not want to shift down often unless you floor it to the click. Even then, sometimes it won't.

I hooked the car up to MB Star, and Some of the diagnostic modules were struggling to read consistently. So I started to replace more stuff. List to follow.

-EGAS Module

-LH Module

-ASR Module

-MAF

-Throttle body

-Crankshaft position sensor (still need to shim it) | Still get this code as well.

-Camshaft position sensor | Still get this code as well.

-Camshaft magnets

-Fuel injectors

-All breather hoses and vacuum lines. (none detected using the smoke test.)

MB star values. Keeping in mind, I have no idea what some of these values mean, I will share in hopes that you do.

First car runs better cold. Idle is smoother and acceleration seems better

LH1

Oxygen sensor voltage Fluxuates between 172 and 660mV.

The car is running idle at around 661 but will dip to low 600.

On/Off ratio cold sticks to about 50% once warm fluxuates between 35 and 41%

EZ1 (006 Current fault Camshaft PS L5/1) Stored Fault: 006 Camshart Position Sensor) I will frequently also get a Crankshaft.

Ignition angle 17.0 but fluxuates (rough idle) down to 13.4 at times.

tml 30 at 14.6V

Intake manifold pressure 655-670 mbar

No readings for ignition voltage or combustion time/cycl. (my other 500 E gave these readings.

DM I cannot get this module to read easily. Is this normal or an issue? Sometimes it will establish communication but more often then not it won't. I was lucky today.

Current fault 022 camshaft

Stored fault 022 camshaft and 013 camshaft.

Actual values indicates that all sensors are reporting back to the DM.

Absol intake manifold pressure is 370 mbar

I can unplug the camshaft sensor and it makes no difference in how the car idles.

I will look for your replies thank you in advance this has been frustrating. Let me know what your next steps would be. I have considered coil, re-gap spark plugs, checking resistance on plug wires. Ignition module. replace O2's. Perhaps the reading above will tell you guys something that I can't see.

Is there a magnet inside on the camshaft itself the shop could have messed up which gives me the CSP error? My wiring harness appears to be dated 4/2009. I did check the wires and they look new. HELP!

-Matt

![[500Eboard] IMG_0291.jpg](/forums/data/attachments/135/135723-93f63ae4dad7b545b225b922cdc7a48f.jpg?hash=k_Y65NrXtU)