What I'd really like is a slightly stiffer spring than stock. ... I've reviewed Dave's documentation on springs but the vast majority of springs in the list are NLA.

Does anyone know if anything is actually available with a stiffer spring rate these days? OE or aftermarket, don't care. What would stock E500E springs do in a 400E?

The 500E front springs may work nicely, as they are probably the second-stiffest available next to the E60 springs... and, I think the 500E may still be available new. You might need to cut them slightly, it will take some trial & error. If NLA, try the Cabrio Sportline front springs instead, which also may be available.

For the rear, see if you can still get the Sportline rears, 124-324-

28-04... MBCC says "available" despite RevParts showing Discontinued, so you'll need to call a dealer and have a live parts person check worldwide inventory in Paragon. The taller version (124-324-

36-04) may be NLA but you could double check. Next available alternative may be the Cabrio rears (124-324-

34-04) but I don't have specs on those, so they'd be a bit of a gamble. Remember the 500E rear springs are designed for SLS and are

way too short for non-SLS use.

Is anyone actually making E60 replicas at this point?

See Tim's post, but these ain't cheap, and the 034 weighs ~200 lbs less so you would likely have to cut new, expensive, replica E60 springs. And, the E60 rear springs are designed for SLS and won't work for a non-SLS application like the 034.

I'm not trying to go super stiff but I figure I'll want to be somewhere between 13.5 and 14 inches all around,

I think your target height is perfect. I like right around 14.0" all around for street use. Pretty sure I already posted photos of our E420 set to a bit over 14.0 with the same CLK forged wheels. You need fabulously good roads where you live to daily drive at 13.0 or less. That ain't Idaho.

and with the suspension stops sitting around 13, that doesn't give me a ton of bump travel before bottoming out. If I'm stuck with just cutting my stock springs I'll probably try to land closer to 14 inches, but if I can find something a little stiffer I'll aim for 13.5. I can definitely build a new lower radiator support to gain back some critical clearance up front.

As an aside, I've found that with new struts, the front ride height is higher vs old/worn struts. Over time (like, 5+ years) the front will gradually sag by a good 1/4", maybe as much as 1/2". I tend to set up the front 1/8-1/4" above my target, knowing it will gradually drop. Oddly, the rear does not experience the same phenomenon. Dial the rear in to your final/target height from day 1.

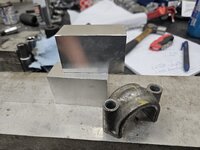

One more ridiculous thought. What about shortening the strut stop buffers? I'm already running the E500E in the front and I believe the Bilstein dampers have the stop built in in the rear right?

If you are using the 036 front stop buffer, I wouldn't cut that down. There should be plenty of travel at 13.5"+ front ride height with 036 strut stop buffers. With your target height, the rear should not be an issue either.

In theory I would think I could buy myself a bit more room in the front by cutting the stops down a bit or even making custom ones. In the Jeep world it's pretty common to do something like machine a hockey puck to fit where you need a custom bump pad. The rear would be a bit more challenging. I think in theory I could raise the upper shock mount. I know that sounds insane. It would require basically cutting out the stock mount and welding in a new mount higher up in the unibody. If that was all it would take I might consider it, but I wouldn't be surprised if things start binding or colliding if the suspension goes beyond its factory limits by much. I do wonder how the guys with the ridiculous bagged suspensions deal with this.

Don't mess with cutting/welding the mounts front or rear. Not worth it, and not needed. The baggers may remove the rear dampers entirely, but remember their goal isn't performance or handling, and is mostly irrelevant. At 13.5-14.0 ride height, damper travel should not be an issue.