Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The $400 400E

- Thread starter Beater400E

- Start date

Pin 6 code 4. Rear axle speed sensor open circuit. Now when I drive it the ABS light comes on and ABS does not work at all. I'm guessing that 300CE sensor is the bad one. More testing...

If my understanding of the sensor is correct, I believe AC voltage should be generated when the ring gear turns. I just put the car on the lift and let the car idle in gear. No voltage. I'm going to swap the original sensor back in and test again.

My theory at this point is that the original sensor was fine, but that I may have tweaked the mounting flange when I removed it to replace the sway bar. The way the flange is bent, the air gap might have been too great for the sensor to pick up low speed pulses. Just a guess. I'm going to try to straighten that mounting tab before I reinstall.

Well, I'm back to where I was at the start of the day. No ABS light, but the ABS still activates during low speed stops. I measured the voltage with the original sensor reinstalled and I'm getting 0.025v AC idling in drive. No idea if that's right or not, but it's something. Better than I was getting with the 300CE sensor.

Given that I have no codes to work with it's safe to assume it could be any of the wheels, or even something else. I gave the front sensors and wires a quick visual inspection and did t notice anything concerning. I guess the next step would be to pull the sensors out of the front wheels and inspect and clean the sensors and tone rings. Does anyone know where the front speed sensors terminate? It would be nice to check those connections as well.

Also, when I was test driving with the 300CE sensor installed, I noticed that if I stood on the gas the ignition would completely cut out after the trans downshifted. Is that normal behavior with an ABS fault? It stopped doing that once I reinstalled the original sensor.

Not to derail things but this is very similar to the issue I'm having. Caps, rotors, wires, Cats, NSS, all replaced. I keep getting EZL code 8. I've swapped LH modules and didnt' help things. I finally have all the parts to do the trans overload switch change and will try to do it soon but I'm calibrating my expectations that this will be a cure all. In particular, your comment about intermittency resonates strongly - on my car, after a cold start I usually have no issue with WOT upshifts, either from start or from a highway pull. But after some time driving (20 mins?) flooring it on the highway results in hesitation, both in 3rd and in 4th, especially in the 4k-5.5k RPM range. I also recently got the cold start upshift delay (code 26).The first few times I stood on it on the highway it downshifted and took off just fine. No problems. Once I had a wide open stretch I stood on it again and let it pull up to about 100. Right at 100 it upshifted to 4th (I think it was 4th anyway) and it started to surge again. From that point on, the issue was back. It's weird. It's almost like it detects something it doesn't like, and then it goes into a failsafe mode. Maybe that's how it's designed. Maybe I'm reading too much into it.

Anywho, it's strange that the car didn't do this with the used switch I had installed, and in fact didn't do this with the brand new switch until a few pulls after I did the diff swap. I think I'll try my other 4.2 EZL and see if that makes a difference. If not maybe I'll go back to the used switch I'd been running and see if that does anything.

Will be positing my progress here on this, fingers crossed we can solve.

Sounds super similar for sure. I still haven't solved it on mine. Once I get the ABS sorted I'll probably try swapping sensors again to see if I can get any different results. Definitely feel free to post here or message me directly if you want to discuss further. I'd love to figure this one out.Not to derail things but this is very similar to the issue I'm having. Caps, rotors, wires, Cats, NSS, all replaced. I keep getting EZL code 8. I've swapped LH modules and didnt' help things. I finally have all the parts to do the trans overload switch change and will try to do it soon but I'm calibrating my expectations that this will be a cure all. In particular, your comment about intermittency resonates strongly - on my car, after a cold start I usually have no issue with WOT upshifts, either from start or from a highway pull. But after some time driving (20 mins?) flooring it on the highway results in hesitation, both in 3rd and in 4th, especially in the 4k-5.5k RPM range. I also recently got the cold start upshift delay (code 26).

Will be positing my progress here on this, fingers crossed we can solve.

I've also tested fuel pressure for a failing pump/regulator and they've been fine, and insulators. I'll be replacing ignition coils soon. I checked for vacuum leaks and found a few....EGR valve gasket, PCV hoses (replacing), valve cover gasket bolt (Replaced), camshaft position sensor (replaced) and then on the LH fender which @gsxr pointed out is bc the MOT purge valve may be stuck open and likely is at my mileage so I need to clean. I wonder if a vacuum leak could cause it.

The real hint here seems to be the fact that it's fine for some time and then appears after 15-20 mins of driving. I wonder if that points more strongly to fuel delivery or something similar. Have you tried swapping the EZL? Isn't that the 'brain' that could be impacting this?

The real hint here seems to be the fact that it's fine for some time and then appears after 15-20 mins of driving. I wonder if that points more strongly to fuel delivery or something similar. Have you tried swapping the EZL? Isn't that the 'brain' that could be impacting this?

I did. The issue remained. In my case the EZL I swapped in was from a 95, which is somehow different from the 92 EZL I should have, but the same issue was there in either case.Have you tried swapping the EZL? Isn't that the 'brain' that could be impacting this?

I'm still most suspicious of the overload switch and its wiring though. Although I've tested and everything seems ok, two different EZLs are telling me the overload switch is not closing. That says to me that for whatever reason the EZL is not seeing that circuit close when it should. So, looking from that point upstream, there could be an issue with two different EZLs (unlikely), or an issue with the wiring from the EZL to the switch, an issue with the switch, or an issue inside the transmission that is preventing the appropriate hydraulic pressure from reaching the switch and closing it.

It's just a two wire circuit, right? Can you run new wires on a piggyback to rule that out, and potentially pin direcly to the switch?

Wiring seems kinda unlikely to be so consistently inconcsistent. Maybe it's something internal to the trans, when it heats up to a certain point? I may need to call Mark at Sun Valley for an issue on another car and will pick his brain on this one.

Wiring seems kinda unlikely to be so consistently inconcsistent. Maybe it's something internal to the trans, when it heats up to a certain point? I may need to call Mark at Sun Valley for an issue on another car and will pick his brain on this one.

Yeah, it's just 2 wires. It would be easy to connect two wires to the switch temporarily, but connecting to the EZL would be more difficult. One of those two wires just goes to ground, so that's easy, but the other one joins up with several other wires inside a harness that goes to one of the larger connectors on the EZL. It would not be easy to connect that wire to the EZL without cutting into that harness and connector.It's just a two wire circuit, right? Can you run new wires on a piggyback to rule that out, and potentially pin direcly to the switch?

Wiring seems kinda unlikely to be so consistently inconcsistent. Maybe it's something internal to the trans, when it heats up to a certain point? I may need to call Mark at Sun Valley for an issue on another car and will pick his brain on this one.

If you haven't yet replaced the switch definitely start there. That's unquestionably the most likely cause. Although I've replaced mine, I'm still not ruling the switch out as the cause. In fact, the issue seemed to be fixed when I had swapped in a used switch, and then it came back once I got a brand new MB switch in and installed it. I plan to swap that used switch back in at some point and see if the issue goes away.

I pulled the front wheel sensors out. The right side was all furry with dirt and metal shavings, and both tone rings were pretty crusty. I pulled the bearings and hubs and spent a little time cleaning the tone rings. Cleaned up the sensors and reassembled everything and... same issue. No codes at this point.

I found the speed sensor connectors and disconnected and measured the AC voltage with the front tires turning. In this case, I just turned the tires by hand. The lowest number I could get was about 0.100v AC, but I could easily get between 0.250-0.400v AC spinning relatively quickly by hand.

My prior test on the rear axle saw right at 0.025v AC. The tires weren't turning very fast during that test, but certainly faster than the fronts were turning when I was seeing around 0.100v. I wish I had some actual specs to work from. At this point I'm suspecting the rear sensor is bad though.

I may see about getting the rear sensor from the 95 E420 in the junk yard near me. These sensors are a little spendy new.

I'm going to see if I can dig up any actual specs or methodical troubleshooting guidance before I pop for a new OE sensor.

I found the speed sensor connectors and disconnected and measured the AC voltage with the front tires turning. In this case, I just turned the tires by hand. The lowest number I could get was about 0.100v AC, but I could easily get between 0.250-0.400v AC spinning relatively quickly by hand.

My prior test on the rear axle saw right at 0.025v AC. The tires weren't turning very fast during that test, but certainly faster than the fronts were turning when I was seeing around 0.100v. I wish I had some actual specs to work from. At this point I'm suspecting the rear sensor is bad though.

I may see about getting the rear sensor from the 95 E420 in the junk yard near me. These sensors are a little spendy new.

I'm going to see if I can dig up any actual specs or methodical troubleshooting guidance before I pop for a new OE sensor.

FWIW, I checked resistance on each of the sensors. The fronts were 1.041 and 1.060. The rear was 0.714.

I found the specs. Front spec is 850-2300 ohms. Rear spec is 600-1600 ohms. That means all 3 are within spec.

That's a good idea.Might be worth getting a cheapy hand oscillisope off amazon. Would allow for more precise visuals of the signals coming from each of the sensors. I think they are fairly affordable these days.

Good news. I figured out what was going on with my ABS. It was an air gap issue with the rear sensor. I installed the 3.06 diff a few weeks ago, and reused my original sensor. When I put the car on the lift to install the sway bars I noticed the bottom of the diff was oily. After poking around I discovered oil was leaking from the ABS sensor hole. I pulled the sensor to swap the sway bar, and while I had it apart I figured I should replace the o ring.

The o ring that was on the sensor was badly smashed and deteriorated, so it was hard for me to figure out what the dimensions were supposed to be. I noticed the o ring groove on the sensor but I was unsure whether that was actually an o ring groove, or just a manufacturing artifact. I concluded at the time that it was not an o ring groove, and I slid on an o ring that I now know had a cross section that was far too thick. When I reinstalled, the o ring would seat right up against the bolt flange. It did seal, so I assumed that's how it was supposed to be.

Turns out that was causing the sensor to deflect a bit and not seat fully into the hole. Today I found a much thinner o ring that I could kind of get to stay in the groove. I'm not thrilled about that design. That groove does not retain the o ring well, and when you try to install the sensor the housing tries hard to push the o ring out of the groove. I eventually got it to go in, and took the car for a drive.

Problem solved! My ABS works normally again.

I'll order a new OE o ring for it shortly.

I also received a set of cheap URO R129 outer sway bar bushings today. I ordered those just so I could get some bushings installed that were at least the right size. I have MB bushings on the way. I got those installed and drove the car. I like the way it handles. The balance feels good to me.

For the record, that was a 92 SL500 front sway bar, and a 2000 E55 rear sway bar. The front is 30mm thick, and the rear is 20mm. I'm using stock R129 bushings all around on the front, and stock E55 frame bushings with custom bushing brackets on the rear, plus a set of W124 wagon metal rear end links that have been machined down to fit the control arm width.

The o ring that was on the sensor was badly smashed and deteriorated, so it was hard for me to figure out what the dimensions were supposed to be. I noticed the o ring groove on the sensor but I was unsure whether that was actually an o ring groove, or just a manufacturing artifact. I concluded at the time that it was not an o ring groove, and I slid on an o ring that I now know had a cross section that was far too thick. When I reinstalled, the o ring would seat right up against the bolt flange. It did seal, so I assumed that's how it was supposed to be.

Turns out that was causing the sensor to deflect a bit and not seat fully into the hole. Today I found a much thinner o ring that I could kind of get to stay in the groove. I'm not thrilled about that design. That groove does not retain the o ring well, and when you try to install the sensor the housing tries hard to push the o ring out of the groove. I eventually got it to go in, and took the car for a drive.

Problem solved! My ABS works normally again.

I'll order a new OE o ring for it shortly.

I also received a set of cheap URO R129 outer sway bar bushings today. I ordered those just so I could get some bushings installed that were at least the right size. I have MB bushings on the way. I got those installed and drove the car. I like the way it handles. The balance feels good to me.

For the record, that was a 92 SL500 front sway bar, and a 2000 E55 rear sway bar. The front is 30mm thick, and the rear is 20mm. I'm using stock R129 bushings all around on the front, and stock E55 frame bushings with custom bushing brackets on the rear, plus a set of W124 wagon metal rear end links that have been machined down to fit the control arm width.

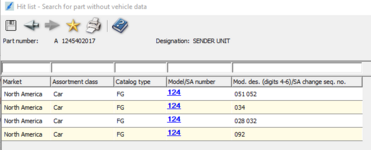

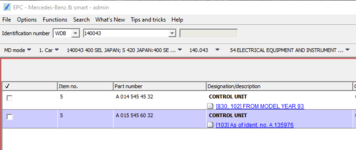

If the ABS sensor has a metal body, it uses O-ring p/n 014-997-97-48, which is fairly thin. $2 MSRP, ~$1.60 or so from discount dealers. Not that you want to change it again, but next time you have a part order going in...

The plastic-body sensors use a different, thicker O-ring p/n 006-997-73-48 that costs twice as much. I've yet to see a plastic-body sensor in a 124.

There's an EPC error which *only* shows the plastic/thicker O-ring for the 124.036 chassis, which caused me a lot of headaches when I first went through this ~15 years ago...

The plastic-body sensors use a different, thicker O-ring p/n 006-997-73-48 that costs twice as much. I've yet to see a plastic-body sensor in a 124.

There's an EPC error which *only* shows the plastic/thicker O-ring for the 124.036 chassis, which caused me a lot of headaches when I first went through this ~15 years ago...

It is a metal body. It's only a 5 minute job to change it when the car is on the lift, so I'll definitely order one with my next parts order.If the ABS sensor has a metal body, it uses O-ring p/n 014-997-97-48, which is fairly thin. $2 MSRP, ~$1.60 or so from discount dealers. Not that you want to change it again, but next time you have a part order going in...

With the Thanksgiving holiday it's been a couple weeks since I've tinkered with the Merc. Finally got back to it today.

I do still need to get the ride height right, but today I decided to do some testing on that stupid downshift problem. As a reminder, what happens is that I'll be driving at 60 mph+, mash the gas, and the car will downshift, and then bog hard for a split second before picking up again and accelerating.

I also am getting a code for the transmission overload switch. I've replaced the switch with a brand new one, and I've checked the wiring. Today I performed two tests.

First, I decided to just confirm that my fuel pressure is good. I didn't really suspect any fuel pressure issues, but I had never done this test so I decided to do it. I connected a fuel pressure gauge to the rail, and then routed it to where I could see it while driving, and then I went and ran my normal test drive. Fuel pressure was solid at roughly 50 psi the whole time.

Next, I devised a test for the transmission overload switch. I put together a breakout connector for the switch, and then ran wires into the cabin connected to a light bulb. When the switch closes, the light bulb lights.

I can confirm that the switch is working. After driving, what I'm seeing is that the switch is closed in 2nd gear, and that's it. The light would light up briefly as the car accelerates through 2nd, and then it goes out when the car upshifts to 3rd. When I'm on the freeway, and doing north of 60, the car will be in 4th. Because I have the 3.06 rear gears, flooring the gas at 60+ results in downshifting to 3rd. With higher (numerically lower) gears, it would have dropped to 2nd, which would not be a problem, but the 3.06 will only allow me to get 3rd at that point. The switch does not close in 3rd, so the EZL does not get the switch closed signal, and does not pull timing.

My guess is that the high load causes the engine to ping, and the knock sensors then step in and stop the fun.

This would likely not be much of an issue in a car with 2.24 gears since a 4-3 downshift would happen at a much higher speed where (I think) loads wouldn't be as high.

Of course, many M119 cars have 2.82 gears. And don't have this issue, so I'm skeptical that the only factor is the gearing. I think it's more likely that the issue was there before, but not really noticeable until I swapped the diff.

So here's the big question. What is the expected behavior of the overload switch? Is it supposed to close in 2nd gear and nothing else? If so, then the transmission and switch are acting correctly, but the EZL/engine are unhappy about it. If not, then the transmission is probably malfunctioning.

I do still need to get the ride height right, but today I decided to do some testing on that stupid downshift problem. As a reminder, what happens is that I'll be driving at 60 mph+, mash the gas, and the car will downshift, and then bog hard for a split second before picking up again and accelerating.

I also am getting a code for the transmission overload switch. I've replaced the switch with a brand new one, and I've checked the wiring. Today I performed two tests.

First, I decided to just confirm that my fuel pressure is good. I didn't really suspect any fuel pressure issues, but I had never done this test so I decided to do it. I connected a fuel pressure gauge to the rail, and then routed it to where I could see it while driving, and then I went and ran my normal test drive. Fuel pressure was solid at roughly 50 psi the whole time.

Next, I devised a test for the transmission overload switch. I put together a breakout connector for the switch, and then ran wires into the cabin connected to a light bulb. When the switch closes, the light bulb lights.

I can confirm that the switch is working. After driving, what I'm seeing is that the switch is closed in 2nd gear, and that's it. The light would light up briefly as the car accelerates through 2nd, and then it goes out when the car upshifts to 3rd. When I'm on the freeway, and doing north of 60, the car will be in 4th. Because I have the 3.06 rear gears, flooring the gas at 60+ results in downshifting to 3rd. With higher (numerically lower) gears, it would have dropped to 2nd, which would not be a problem, but the 3.06 will only allow me to get 3rd at that point. The switch does not close in 3rd, so the EZL does not get the switch closed signal, and does not pull timing.

My guess is that the high load causes the engine to ping, and the knock sensors then step in and stop the fun.

This would likely not be much of an issue in a car with 2.24 gears since a 4-3 downshift would happen at a much higher speed where (I think) loads wouldn't be as high.

Of course, many M119 cars have 2.82 gears. And don't have this issue, so I'm skeptical that the only factor is the gearing. I think it's more likely that the issue was there before, but not really noticeable until I swapped the diff.

So here's the big question. What is the expected behavior of the overload switch? Is it supposed to close in 2nd gear and nothing else? If so, then the transmission and switch are acting correctly, but the EZL/engine are unhappy about it. If not, then the transmission is probably malfunctioning.

Interesting hypothesis. Do you notice the same pinging in other gears/during WOT at other times?

Maybe at high speed you're getting a ton of air into the engine? But shouldn't the MAF/ETA be compensating for this?

Maybe at high speed you're getting a ton of air into the engine? But shouldn't the MAF/ETA be compensating for this?

It does not ping when downshifting to 2nd or to 1st. The fact that it doesn't ping in 2nd probably has to do with the overload switch. I don't think it's going lean. I think the cylinder pressure is too high for the ignition advance at that moment, and the EZL is not being commanded to pull timing, so it's detonating rather than burning smoothly.Interesting hypothesis. Do you notice the same pinging in other gears/during WOT at other times?

Maybe at high speed you're getting a ton of air into the engine? But shouldn't the MAF/ETA be compensating for this?

Really, what's the difference between 3rd gear with 3.06 gears and 2nd gear with 2.24 gears? There's not much difference really, but the overload switch doesn't close in 3rd, at least in my car, so the EZL doesn't pull timing.

I pulled a 2 pin male connector and a 2 pin female connector off my S500 parts car. I cut the retaining clips off the connectors, then spliced the two together and plugged the assembly between the overload switch and its harness. Then I tapped into the wire in line with the output leg of the switch, which leads to the EZL. That became my switched ground for the bulb. Then I just grabbed 12v+ off a fuse and ran that in to the other side of the bulb.Thats a really neat approach you took. How did you splice in the bulb? If its easy enough and reversible, a couple of us may be able to try it out ourselves and report back …

In theory it could be done with male and female bullet connectors if you don't have a parts car to cut up. It's just a matter of putting something in line between the switch and the factory connector so you can splice into it without hacking the factory wires.

Can you audibly hear pinging? If not, it's unlikely there is ignition retard occurring enough to feel a power loss. When retard hits the maximum (-12°) the EZL will store a code. You can view live retard values with HHT-Win on SDS, although it's tricky at WOT without a second person (don't try this at home, kiddos!)

MPH is irrelevant. The ECU's only know load and RPM's. The fact those are now at lower speeds due to 3.06 gears doesn't matter.

MPH is irrelevant. The ECU's only know load and RPM's. The fact those are now at lower speeds due to 3.06 gears doesn't matter.

I don't hear pinging, and there isn't a code for it.Can you audibly hear pinging? If not, it's unlikely there is ignition retard occurring enough to feel a power loss. When retard hits the maximum (-12°) the EZL will store a code. You can view live retard values with HHT-Win on SDS, although it's tricky at WOT without a second person (don't try this at home, kiddos!)

MPH is irrelevant. The ECU's only know load and RPM's. The fact those are now at lower speeds due to 3.06 gears doesn't matter.

If the EZL is expecting to see the overload switch close at certain times, and it throws a code when the switch does not close at the expected time, I have to wonder what parameters the EZL uses to judge that the overload switch should close. It obviously knows RPMs. It knows MAP vacuum. Does it need to know which gear the trans is in, or should it be responding the same in all gears? If that's the case, then it seems odd that the overload switch is only closed in 2nd gear.

Good question about the EZL and gears. I'm not sure if it "knows" what gear the transmission is in, or if it behaves the same for all upshifts (but I think it should).

The O/L switch measures B1 mvoement / pressure, correct? But does B1 engage/disengage for all upshifts?

The O/L switch measures B1 mvoement / pressure, correct? But does B1 engage/disengage for all upshifts?

My transmission acts healthy. I don't know exactly when B1 engages/disengages, but I think it's plausible that it only engages in 2nd gear. If that is the case, then there is no way that the overload would ever close during a 4-3 downshift. If the EZL has no way of knowing which gear the transmission is in, then it could only judge whether the overload switch should close by looking at RPMs, engine vacuum, knock sensor output, and whatever other data it receives.Good question about the EZL and gears. I'm not sure if it "knows" what gear the transmission is in, or if it behaves the same for all upshifts (but I think it should).

The O/L switch measures B1 mvoement / pressure, correct? But does B1 engage/disengage for all upshifts?

My theory (fear) is that the 3.06 gears have essentially made it so 3rd gear now sees the same kinds of loads that 2nd gear normally would, but without the benefit of the overload switch to help the EZL proactively pull timing during a downshift into 3rd, it sees enough load (vacuum drop, and possibly knocking) that it has to pull timing reactively instead, which is why it sets the code and bogs at that point.

I could definitely be wrong on that. If it is something else, I can't even guess what else it would be. The overload switch is working exactly as it should, but the car stumbles badly on 4-3 downshifts and sets the code every time.

EDIT: Some of the assumptions I made in this post were incorrect. I was wrong about how the EZL functions. Later posts in this thread have a more accurate description of its function.

The EZL thinks 3rd gear is 2nd.

This is going to be a long post.

Ok, I'm pretty sure I figured out what is going on. I was able to temporarily fix it, but I'm not sure what the permanent fix would be.

As a reminder, I'm dealing with a code 8 on pin 17, which is "transmission overload switch doesn't close" and the car hesitates when downshifting from 4th to 3rd, especially above 70 mph. The car has a 3.06 rear diff.

When I first bought the car, it had a similar issue in 2nd gear. I ended up replacing the overload switch and the issue went away until I swapped in the 3.06 differential. After the differential swap the issue popped up in 3rd gear.

I checked the function of the overload switch by wiring a light bulb in line and confirming that the switch closes when the car is in 2nd. It will not close in any other gear.

I found the following information on EZL operation:

OPERATION

The EZL/AKR control module receives information concerning:

^ Voltage supply (+)

^ Engine speed from crankshaft position sensor (L5)

^ Cylinder #1 position from camshaft position sensor (L5/1)

^ Engine load condition from intake manifold vacuum signal

^ Selection of ignition map from EZL/AKR reference resistor (R16/2)

^ Shift preconditions from transmission overload protection switch (S65)

^ Combustion knock from knock sensors (A16)

^ Fuel injection information from LH control module (N3/1)

^ Throttle position from:

W/O ASR: Cruise control/idle speed control module (N4/3)

W ASR : Electronic accelerator control module (N4/1)

^ ABS/ASR information from ABS/ASR control module (N30/1)

The EZL/AKR control module compares information from these inputs with ignition maps for typical load and speed ranges which are stored in the microcomputer. The optimal ignition timing for each operating condition is instantaneously determined from the stored maps and the power output stage switches the primary current of the ignition coil.

Furthermore, a TD (engine speed) reference signal is provided to the LH control module, tachometer, on-board diagnostic connector, and the diagnostic socket. To further increase operating reliability, a data exchange circuit has been added between the EZL/AKR control module and the LH control module. Information concerning the coolant temperature, intake air temperature and the intake manifold absolute pressure is continuously compared by the control module of each system.

During cranking and up to approx. 450 RPM, the ignition timing is controlled via the segment edges (fixed) of the flywheel. After approx. 460 RPM has been attained a transition from the fixed ignition timing to dynamic ignition timing (instantaneous, ignition map comparison) is made. Various ignition characteristic curves are inhibited in the warm-up range depending on the coolant temperature in order to reach the normal operating temperature as rapidly as possible.

When a full load signal is received from the cruise control/idle speed control (N4/3) or electronic accelerator control module (N4/1), the EZL/AKR control module adapts a fixed full load ignition map characteristic. At temperatures above approx. 203°F the ignition will be retarded to counter any further rise in temperature.

Note that there is no mention of any signal indicating which gear the transmission is in. The overload switch only functions in 2nd gear, so how does the EZL know the car is in 2nd?

Engine load. How is engine load measured? Vacuum.

There is a vacuum line connected to the EZL to provide manifold absolute pressure, which the EZL uses to determine engine load, and thereby INFER which gear the transmission is in. The reason 2nd gear is the only gear with an overload switch is because that's the gear where the engine load is highest, and thereby the gear where the torque load on the transmission is highest.

Why is 2nd gear the gear with the highest load? I'm not 100% sure on this, but I think the load is a function of the combined transmission and differential gear ratio, along with MPH and engine RPMs.

So why do I believe the EZL thinks 3rd is 2nd? Well, it's reacting just like it would if the overload switch was not closing in 2nd, and with the 3.06 differential, I've brought the 3rd gear load very close to the factory 2nd gear load.

2nd gear has a ratio of 2.24:1. The factory differential ratio was also 2.24:1. Multiplying those together give a total gear reduction of 5.02:1.

3rd gear is 1.44:1. Multiply that by 2.24 gets 3.23. So the stock total gear reduction in second and third are 5.02 and 3.23.

With 3.06 gears that becomes 6.85 and 4.41. So, originally 2nd was 5.02 and now 3rd is 4.41. My theory is that this is close enough that the engine load in 3rd is now high enough that the car thinks 3rd is 2nd, so it pulls timing and then waits for the overload switch, which never comes.

Nice theory, but can I prove it? I thought of a test.

I got a vacuum check valve and installed it in the vacuum line going to the EZL. The idea is that at low load, high vacuum, the engine pulls vacuum through the check valve, but then when I stand on it, the check valve prevents vacuum drop, which tricks the EZL into believing that it's not in 2nd.

I took the car out and ran it and it worked.

THE ISSUE IS GONE.

Unfortunately, this cannot be a permanent solution. This causes the EZL to always run timing maps corresponding to high vacuum.

I need to devise a permanent solution.

Here are the ideas so far.

First, I need to check very carefully for vacuum leaks. If there are leaks, it would cause the maximum vacuum signal to the EZL to be lower, and the high load signal to be lower as well. If that lower vacuum signal is below a certain threshold, the EZL will believe it's in 2nd. Maybe by fixing vacuum leaks, the signal will end up back in the normal range for 3rd.

Next option would be to try introducing a restriction and/or vacuum reservoir that will slow the release of vacuum. I don't know exactly what configuration would help. It would probably require some trial and error. The trick is that I'd need to find a solution that would allow 3rd gear to work without the EZL pulling timing, but not prevent the EZL from pulling timing in 2nd.

Another option would be a different EZL. It's possible that other EZLs, or possibly even other EZL map resistors might give me a map that would work with the vacuum signals I'm getting.

If anyone has any thoughts, feedback, ideas, general ill-will, or miraculous solutions, feel free to leave them here.

The EZL thinks 3rd gear is 2nd.

This is going to be a long post.

Ok, I'm pretty sure I figured out what is going on. I was able to temporarily fix it, but I'm not sure what the permanent fix would be.

As a reminder, I'm dealing with a code 8 on pin 17, which is "transmission overload switch doesn't close" and the car hesitates when downshifting from 4th to 3rd, especially above 70 mph. The car has a 3.06 rear diff.

When I first bought the car, it had a similar issue in 2nd gear. I ended up replacing the overload switch and the issue went away until I swapped in the 3.06 differential. After the differential swap the issue popped up in 3rd gear.

I checked the function of the overload switch by wiring a light bulb in line and confirming that the switch closes when the car is in 2nd. It will not close in any other gear.

I found the following information on EZL operation:

OPERATION

The EZL/AKR control module receives information concerning:

^ Voltage supply (+)

^ Engine speed from crankshaft position sensor (L5)

^ Cylinder #1 position from camshaft position sensor (L5/1)

^ Engine load condition from intake manifold vacuum signal

^ Selection of ignition map from EZL/AKR reference resistor (R16/2)

^ Shift preconditions from transmission overload protection switch (S65)

^ Combustion knock from knock sensors (A16)

^ Fuel injection information from LH control module (N3/1)

^ Throttle position from:

W/O ASR: Cruise control/idle speed control module (N4/3)

W ASR : Electronic accelerator control module (N4/1)

^ ABS/ASR information from ABS/ASR control module (N30/1)

The EZL/AKR control module compares information from these inputs with ignition maps for typical load and speed ranges which are stored in the microcomputer. The optimal ignition timing for each operating condition is instantaneously determined from the stored maps and the power output stage switches the primary current of the ignition coil.

Furthermore, a TD (engine speed) reference signal is provided to the LH control module, tachometer, on-board diagnostic connector, and the diagnostic socket. To further increase operating reliability, a data exchange circuit has been added between the EZL/AKR control module and the LH control module. Information concerning the coolant temperature, intake air temperature and the intake manifold absolute pressure is continuously compared by the control module of each system.

During cranking and up to approx. 450 RPM, the ignition timing is controlled via the segment edges (fixed) of the flywheel. After approx. 460 RPM has been attained a transition from the fixed ignition timing to dynamic ignition timing (instantaneous, ignition map comparison) is made. Various ignition characteristic curves are inhibited in the warm-up range depending on the coolant temperature in order to reach the normal operating temperature as rapidly as possible.

When a full load signal is received from the cruise control/idle speed control (N4/3) or electronic accelerator control module (N4/1), the EZL/AKR control module adapts a fixed full load ignition map characteristic. At temperatures above approx. 203°F the ignition will be retarded to counter any further rise in temperature.

Note that there is no mention of any signal indicating which gear the transmission is in. The overload switch only functions in 2nd gear, so how does the EZL know the car is in 2nd?

Engine load. How is engine load measured? Vacuum.

There is a vacuum line connected to the EZL to provide manifold absolute pressure, which the EZL uses to determine engine load, and thereby INFER which gear the transmission is in. The reason 2nd gear is the only gear with an overload switch is because that's the gear where the engine load is highest, and thereby the gear where the torque load on the transmission is highest.

Why is 2nd gear the gear with the highest load? I'm not 100% sure on this, but I think the load is a function of the combined transmission and differential gear ratio, along with MPH and engine RPMs.

So why do I believe the EZL thinks 3rd is 2nd? Well, it's reacting just like it would if the overload switch was not closing in 2nd, and with the 3.06 differential, I've brought the 3rd gear load very close to the factory 2nd gear load.

2nd gear has a ratio of 2.24:1. The factory differential ratio was also 2.24:1. Multiplying those together give a total gear reduction of 5.02:1.

3rd gear is 1.44:1. Multiply that by 2.24 gets 3.23. So the stock total gear reduction in second and third are 5.02 and 3.23.

With 3.06 gears that becomes 6.85 and 4.41. So, originally 2nd was 5.02 and now 3rd is 4.41. My theory is that this is close enough that the engine load in 3rd is now high enough that the car thinks 3rd is 2nd, so it pulls timing and then waits for the overload switch, which never comes.

Nice theory, but can I prove it? I thought of a test.

I got a vacuum check valve and installed it in the vacuum line going to the EZL. The idea is that at low load, high vacuum, the engine pulls vacuum through the check valve, but then when I stand on it, the check valve prevents vacuum drop, which tricks the EZL into believing that it's not in 2nd.

I took the car out and ran it and it worked.

THE ISSUE IS GONE.

Unfortunately, this cannot be a permanent solution. This causes the EZL to always run timing maps corresponding to high vacuum.

I need to devise a permanent solution.

Here are the ideas so far.

First, I need to check very carefully for vacuum leaks. If there are leaks, it would cause the maximum vacuum signal to the EZL to be lower, and the high load signal to be lower as well. If that lower vacuum signal is below a certain threshold, the EZL will believe it's in 2nd. Maybe by fixing vacuum leaks, the signal will end up back in the normal range for 3rd.

Next option would be to try introducing a restriction and/or vacuum reservoir that will slow the release of vacuum. I don't know exactly what configuration would help. It would probably require some trial and error. The trick is that I'd need to find a solution that would allow 3rd gear to work without the EZL pulling timing, but not prevent the EZL from pulling timing in 2nd.

Another option would be a different EZL. It's possible that other EZLs, or possibly even other EZL map resistors might give me a map that would work with the vacuum signals I'm getting.

If anyone has any thoughts, feedback, ideas, general ill-will, or miraculous solutions, feel free to leave them here.

Last edited by a moderator:

Great research! One minor problem though. Euro models have a 2.65 differential and the identical EZL part numbers. It seems odd that only 3.06 gears would cause this problem. The trim plugs (resistors) only pull timing, for use of lower-octane fuel... I don't think any of those will help.

Next question: What specific EZL part number do you have installed? What EZL part numbers do you have as spares to experiment with?

Next question: What specific EZL part number do you have installed? What EZL part numbers do you have as spares to experiment with?

Great research! One minor problem though. Euro models have a 2.65 differential and the identical EZL part numbers. It seems odd that only 3.06 gears would cause this problem. The trim plugs (resistors) only pull timing, for use of lower-octane fuel... I don't think any of those will help.

Next question: What specific EZL part number do you have installed? What EZL part numbers do you have as spares to experiment with?

I agree that I may be missing something here, but I think I'm closing in on it. My theory was that the 3.06 is far enough from 2.65 that it crosses the critical threshold for vacuum drop. It's also possible that while the vacuum check valve did eliminate the symptom, it did so for some reason other than what I guessed. I have not cleared codes and then run with the check valve to see if the code returns. That would probably be a valuable data point. I'll probably run that test before I do anything else just to see what happens.

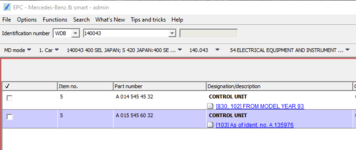

I currently have EZL 013-545-63-32 installed. That's the original 92 400E EZL I believe.

I have a 015-545-60-32 from a 95 E420, which I ran in the car for a time. The car behaved the same with that EZL installed.

I also have a 014-545-43-32 from my 95 S500. I haven't tried that one yet.

I still have a 008-545-95-32 from my 90 300E 2.6, but I'm sure that's no help here.

I ordered a smoke machine to help search for vacuum leaks. That will be my first step. After that I may try the S500 EZL, but I'd be surprised if that works.

I wonder if an EZL from an S420 with a 2.82 might work. That's the numerically highest ratio I know of with the 4.2 engine. An E500 EZL might also be an option.

Granted, even if I solve this now, I may be having to do it all over again once I swap in the 5 liter. Hopefully whatever I figure out here will translate to the new combo after the swap.

The 140 chassis with 4.2L engine use identical EZL part numbers as the 400E / E420, although with different chassis break points of course.

012- was used in 1992 (10:1 compression engine, early chassis, supercedes to 013-)

013- was used in 1992 (10:1 compression engine)

014- was used in 1993 (11:1 compression engine)

015- was used in 1994-95 (11:1 compression engine, with open-deck block, after chassis break point shown)

012- was used in 1992 (10:1 compression engine, early chassis, supercedes to 013-)

013- was used in 1992 (10:1 compression engine)

014- was used in 1993 (11:1 compression engine)

015- was used in 1994-95 (11:1 compression engine, with open-deck block, after chassis break point shown)

That would most likely support the idea that my issue could be a vacuum leak. That, or there's something else involved in the EZL deciding what is 2nd gear and what is not.The 140 chassis with 4.2L engine use identical EZL part numbers as the 400E / E420, although with different chassis break points of course.

012- was used in 1992 (10:1 compression engine, early chassis, supercedes to 013-)

013- was used in 1992 (10:1 compression engine)

014- was used in 1993 (11:1 compression engine)

015- was used in 1994-95 (11:1 compression engine, with open-deck block, after chassis break point shown)

View attachment 180144

View attachment 180143

Love all this work @Beater400E ! Super interesting to push forward our understanding of this.

On the smoke test, I just use an old soldering iron, a bike pump, old rags, and baby oil. Works well in my experience but looks real janky

On the smoke test, I just use an old soldering iron, a bike pump, old rags, and baby oil. Works well in my experience but looks real janky

There has to be more to it than just vacuum. I get 18 inches mercury at idle, and even in park it drops to zero at WOT. It's going to drop to zero at WOT in every gear. It can't be determining which gear it's in by vacuum alone. Interesting that vacuum is involved. If I had to guess, I'd say load is A factor, but not the ONLY factor. It makes sense that it would need to see a vacuum drop before it pulls timing. Otherwise it would pull timing EVERY time the transmission shifts to 2nd. So the check valve hides the problem, but the real problem is still there. There must be something else that helps the EZL determine when the car is in 2nd gear. How else could it be deciding whether it's in 2nd?

I reached out to a Mercedes technician on YouTube about this. He sent me the following taken directly from his books:

In order to protect the shift elements or the

automatic transmission from excessive thermal

stresses during power shifts in the top engine

speed range, a transmission overload protection

is integrated in the EZL ignition control units.

As a result of the transmission overload

protection, ignition timing is retarded to 5° CA

before TDC for about 400 ms (reduced engine

torque) during 1 + 2 and 2 + 3 upshifts.

As this retardation of ignition timing during the

shifting phase also provides a smoother

gearshift, this measure is also used during

3 to 2 full load downshifts.

Ignition timing is retarded provided the following

conditions are met simultaneously:

Engine speed >4000/rpm (reference value)

Vacuum in intake manifold <300 mbar

(reference value)

Shift signal from transmission overload

protection switch, brake band B1 (S65).

The transmission overload protection switch,

brake band B1 (S65) is designed as a

hydraulic switch and linked to the operating

pressure circuit of brake band "B1', and "B2,

respectively, of the automatic transmission.

The opening and closing of the transmission

overload protection switch, brake band B1 (S65)

is detected as a shift signal by the

appropriate EZL ignition control unit.

The shift function of the transmission overload

protection switch, brake band B1 (S65) is

dependent on the working pressure which exists

at "B1".

Working pressure < 1.8 bar: S65 opened.

Working pressure > 1.8 bar: S65 closed.

If I'm understanding this correctly, the overload switch is the only indication of a shift the EZL gets. The EZL recognizes that the switch went from opened to closed in a 1-2 or 3-2 shift, or from closed to open on a 2-3 shift, or I suppose a 2-1 shift. It would see any of those changes in state as an indication of a shift and if the RPMs are above 4k rpm and the manifold pressure is below 300 mbar, which is like 9 inches mercury, it will drop to 5 degrees BTDC for 400 milliseconds.

This information does not support the idea that the overload switch closing RESTORES the timing. Instead it suggests that timing will be reduced to 5 degrees for 400 milliseconds for every shift that meets those conditions. That doesn't seem right to me, so I don't know what to think.

My 4-3 hesitation does feel like exactly that. Timing dropped to 5 degrees for 400 milliseconds. According to the above info that shouldn't be possible though since the overload switch is open and 4th, and does not close at any point when it downshifts to 3rd.

In order to protect the shift elements or the

automatic transmission from excessive thermal

stresses during power shifts in the top engine

speed range, a transmission overload protection

is integrated in the EZL ignition control units.

As a result of the transmission overload

protection, ignition timing is retarded to 5° CA

before TDC for about 400 ms (reduced engine

torque) during 1 + 2 and 2 + 3 upshifts.

As this retardation of ignition timing during the

shifting phase also provides a smoother

gearshift, this measure is also used during

3 to 2 full load downshifts.

Ignition timing is retarded provided the following

conditions are met simultaneously:

Engine speed >4000/rpm (reference value)

Vacuum in intake manifold <300 mbar

(reference value)

Shift signal from transmission overload

protection switch, brake band B1 (S65).

The transmission overload protection switch,

brake band B1 (S65) is designed as a

hydraulic switch and linked to the operating

pressure circuit of brake band "B1', and "B2,

respectively, of the automatic transmission.

The opening and closing of the transmission

overload protection switch, brake band B1 (S65)

is detected as a shift signal by the

appropriate EZL ignition control unit.

The shift function of the transmission overload

protection switch, brake band B1 (S65) is

dependent on the working pressure which exists

at "B1".

Working pressure < 1.8 bar: S65 opened.

Working pressure > 1.8 bar: S65 closed.

If I'm understanding this correctly, the overload switch is the only indication of a shift the EZL gets. The EZL recognizes that the switch went from opened to closed in a 1-2 or 3-2 shift, or from closed to open on a 2-3 shift, or I suppose a 2-1 shift. It would see any of those changes in state as an indication of a shift and if the RPMs are above 4k rpm and the manifold pressure is below 300 mbar, which is like 9 inches mercury, it will drop to 5 degrees BTDC for 400 milliseconds.

This information does not support the idea that the overload switch closing RESTORES the timing. Instead it suggests that timing will be reduced to 5 degrees for 400 milliseconds for every shift that meets those conditions. That doesn't seem right to me, so I don't know what to think.

My 4-3 hesitation does feel like exactly that. Timing dropped to 5 degrees for 400 milliseconds. According to the above info that shouldn't be possible though since the overload switch is open and 4th, and does not close at any point when it downshifts to 3rd.

Last edited:

The info above is from the FSM, job 15-0200 15-0020, section J, "Transmission Overload Protection"... PDF pages 30-31 of 32. Had you not seen that yet?

Last edited:

I had not seen that. That's great info, and gives me more to investigate. Thanks Dave.The info above is from the FSM, job 15-0200, section J, "Transmission Overload Protection"... PDF pages 30-31 of 32. Had you not seen that yet?

I believe the changing in states of the overload protection switch from open to closed or closed to open is the primary indication that a shift is occurring, and that in normal operation the EZL will retard timing to 5 degrees BTDC for 400 ms and that's it.

I'd previously read forum posts indicating that the switch was used to reduce the duration of the timing retardation, but I don't think that is accurate.

The documentation also talks about emergency running mode transmission overload protection, where the EZL does not detect the overload switch while driving, in which case it switches to emergency protection where it determines shifting by change in RPMs only. If that were happening, it would affect the 4-3 shift for sure. The emergency overload protection information also describes my exact symptom: retardation of ignition timing at high speed.

I'm guessing that if I reset the code and go drive it, the issue will be gone until at some point the EZL decides it's not seeing the signal from the overload switch, at which point it goes into emergency mode until the code is reset again.

Although I could see the switch was functioning correctly with my light bulb trick, I could not verify the EZL was actually receiving the signal from the switch since I'd tapped into the switch itself. Maybe I need to try to make a breakout connector at the EZL to confirm signal at the EZL.

I suppose it's also possible that I have two bad EZLs. I could try the S500 EZL and see if anything changes.

Last edited:

I think it's fixed.

I swapped in the S500 EZL and now the car is perfect. No more hesitation on shifts. No more codes.

I drove it about 40 miles on the freeway, aggressively abusing it between about 70 and 110 mph to try to induce a problem, and it was just perfect the whole time. When I got back I scanned it and found zero codes.

It would appear that I was chasing ghosts thanks to a pair of similarly malfunctioning EZLs.

I swapped in the S500 EZL and now the car is perfect. No more hesitation on shifts. No more codes.

I drove it about 40 miles on the freeway, aggressively abusing it between about 70 and 110 mph to try to induce a problem, and it was just perfect the whole time. When I got back I scanned it and found zero codes.

It would appear that I was chasing ghosts thanks to a pair of similarly malfunctioning EZLs.

No doubt. I resisted trying this 3rd EZL for a long time because I figured it was so unlikely to be the EZL since the first two acted the same. One was original to the car. The other I got from a local junk yard. The EZL that fixed it came from my S500 parts car.Kinda nuts that two would behave the exact same way. Where did you get them? Ebay?

I don't think the gear ratio was a factor. The way the EZL works it just looks for a change in state of the overload switch from open to closed or closed to open to identify that a gear change has occurred. In my case, I believe I had two malfunctioning EZLs, both of which were unable to see the overload switch at all. That made them both go into fault mode, where they use a far more aggressive timing reduction strategy, which caused the symptom I was feeling. The manifold vacuum signal is only a factor in that the EZL needs to see vacuum below 300 millibars at 4000 RPMs or higher when the overload switch changes state in order to initiate a drop to 5 degrees BTDC for 400 ms. That's it. The gear ratio doesn't matter at all since vacuum drops way lower than 300 mb any time the car is at WOT.Poking at your original analysis, wonder what the gear ratio math works out to be for all the trans/rear diff ratios across all the models that the s500 EZL P/N was used on. Perhaps it ‘covers’ a wider range than the e420 PN?

I had made assumptions based on the idea that the EZLs must be good since both did the same thing. Also, the description I had previously read of the overload switch and EZL function was incorrect. The overload switch is not used to "restore" timing following a shift. It's used to identify that the shift is occurring in the first place. The duration of the timing retard is the same every time as long as the fault condition is not set.

The link Dave posted above is very helpful. One note, Dave referenced job 15-0200. I believe that was a typo. It's actually job 15-0020. The last few pages describe the function of the EZL very well.

Dumb question, but what LH module part number is currently installed? Also, this is a 1992 400E 4.2L engine with 10:1 compression, correct?

I've never heard of an EZL failure as described above, I 'm suspicious there's something else going on, but I'm glad the different EZL worked!

BTW - the EZL should not remain in a "fault" mode. It will store a code that will not go away until manually cleared, but as soon as the EZL sees data that it's happy with again, timing/retard will be normal until the next occurrence of data it isn't happy with.

Good catch on my typo, btw - yes, it was 15-0020! Previous post edited.

I've never heard of an EZL failure as described above, I 'm suspicious there's something else going on, but I'm glad the different EZL worked!

BTW - the EZL should not remain in a "fault" mode. It will store a code that will not go away until manually cleared, but as soon as the EZL sees data that it's happy with again, timing/retard will be normal until the next occurrence of data it isn't happy with.

Good catch on my typo, btw - yes, it was 15-0020! Previous post edited.

The LH is 012-545-30-32. I believe it is original to the car. I believe the engine is also original. It's an early 4.2. It has no mounting boss on the timing cover for the later belt tensioner, so I'm sure it's a 10:1 motor.Dumb question, but what LH module part number is currently installed? Also, this is a 1992 400E 4.2L engine with 10:1 compression, correct?

Good to know. Thanks for clarifying.BTW - the EZL should not remain in a "fault" mode. It will store a code that will not go away until manually cleared, but as soon as the EZL sees data that it's happy with again, timing/retard will be normal until the next occurrence of data it isn't happy with.

I think I finally got the ride height where I want it. I took the H&R springs back out of the rear, and then cut 1 coil off the stock rear springs and reinstalled them with the 1 bump pads in the rear. That, along with the H&R springs and 3 bump pads in the front put me at 13-1/2 inches up front and 13-3/4 in the rear. I have between 3/4 and 1 inch downtravel available on all 4 corners, so I think I'm good to go.

Now I just need to get the car aligned. @gsxr Dave is there a shop in town you recommend for alignment work on our cars?

Now I just need to get the car aligned. @gsxr Dave is there a shop in town you recommend for alignment work on our cars?

Similar threads

- Replies

- 3

- Views

- 212

- Replies

- 12

- Views

- 1,377

- Replies

- 2

- Views

- 273

Similar threads

- Replies

- 3

- Views

- 212