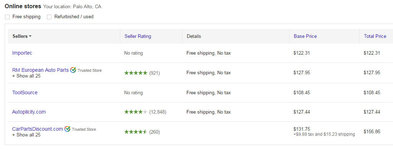

Must be a Google thing... it knows you are not in the USA and is blocking the prices. I'm seeing ~$125 USD over on this side of the pond from a few vendors, screen shot attached.

eBay link, seller will ship worlwide:

http://www.ebay.com/itm/New-Baum-Tools-116-0140-Flywheel-Lock-Tool-/151906010889

eBay link, seller will ship worlwide:

http://www.ebay.com/itm/New-Baum-Tools-116-0140-Flywheel-Lock-Tool-/151906010889

Why didn't the factory create something like that?

Why didn't the factory create something like that?

Check out the pic-

Check out the pic-