I recently was able to obtain a set of used, but good condition, metal M119 camshaft oiler tubes from a 500Eboard member. I decided to begin the installation procedure and finish it up this coming week as I get the E500 prepared for the trip to MBCA's StarTech meeting in Alabama during the middle of May.

This job overall is not very hard, but it is labour-intensive and requires one to pay attention. It also requires that you have a number of parts on hand, that need to be replaced during the procedure. I would say it would take the average person about 4-5 hours to do this job, perhaps more. I spent three hours alone on the passenger side engine bank, simply because I took my time and cleaned up everything I found.

The following types of tools will be required:

- various sizes of flat-blade screwdrivers

- 1/4" and 3/8" ratchets, extensions

- 11mm socket (1/4 and 3/8" sizes)

- can or two of brake cleaner

- 3-4 shop rags

- flashlight or other strong light source

- torque wrench

- 5mm flex-head allen socket

- 5mm regular allen socket

- Needle-nose or standard pliers

The following MB parts

* are HIGHLY recommended for this job:

- valve cover gasket kits for left and right side engine banks (MB part numbers 119 010 13 30 and 119 010 14 30)

- 18 copper "crush" washers for valve cover bolts (MB part number N007603 006106)

- Replacement metal cam oiler tubes (16)

- Upper plastic chain rail guides (MB part numbers 119 052 09 16 (two required); 119 050 03 16; and 119 050 02 16)

- 32 new o-rings for replacement cam oiler tubes (MB part number 015 997 31 48)

*GSXR note: "MB parts" means "Genuine Mercedes" only, not aftermarket, i.e. not Victor valve cover gaskets.

Here's the procedure I followed. The first post will be for the passenger side of the engine. The second post will be for the driver's side. It's also a good idea to replace the spark plugs when you are doing this job; they are rarely so accessible. If you have more than 20K miles on your plugs, you should plan to do the plugs.

First of all, a view of the engine as the hood is opened, and with the air intake "zoom" tubes, air box and plastic vanity panel removed.

View attachment 15429 View attachment 15431

If anyone is interested, here's the solenoid setup for the nitrous-oxide injection system, that sits on the inner firewall just behind the airbox.

View attachment 15433

Next up is to remove the plastic panel that covers the distributor and cam advance solenoid. This just unclips and lifts off. Then, it's time to take a large flat-blade screwdriver, and remove the two plastic bolts that hold the ignition and spark plug wire cover to the aluminum valve covers. Photos 3 and 4 below show the plastic cover coming off, and what's underneath it.

View attachment 15435 View attachment 15437 View attachment 15439 View attachment 15441

The next step is to remove these two wiring bundles from their secured point to the top of the valve cover. The flat metal plate holds them to the valve cover, and the plate is attached by two 5mm allen head bolts, which are removed with ease. Note that one bolt is longer than the other. The longer bolt goes on the side toward the passenger compartment (firewall) - something to remember at re-assembly time.

View attachment 15443 View attachment 15445 View attachment 15447 View attachment 15449 View attachment 15451 View attachment 15453

For future reference, here's how the ignition wires are routed to the passenger-side engine bank.

View attachment 15455 View attachment 15457

Then it's time to remove the spark plug connectors, and the breather hose at the bank of the valve cover. The clamp can be squeezed together with a pair of needle nose or channel-lock pliers to release it, and then the hose can just be twisted off the fitting.

View attachment 15459 View attachment 15461

I also took the time to remove the two 5mm allen bolts that held the black plastic wire routing piece atop the cylinder head. I move then back a couple of inches toward the MAF, as shown. This was to provide more clearance/room for the next steps.

View attachment 15463

Here begins the process of removing the nine valve cover bolts. The pivoting-head 5mm 1/4" socket came in extremely handy for both the front and rear corner bolts, which would have been EXTREMELY difficult to remove otherwise. This tool is almost imperative for the job. Make sure you get it before you remove the valve covers.

View attachment 15465 View attachment 15467 View attachment 15469 View attachment 15471 View attachment 15473 View attachment 15475

Here's the bolts, laid out in the correct order on my work table. Notice that the middle bolt at the front of the motor is longer than the others.

View attachment 15477

Then, I pried loose the cam cover with a large flat-blade screwdriver and carefully removed it from the top of the cylinder head. Notice that three of the four spark plug boots stayed attached to the head, not the valve cover. These boots will be pried off and removed later. All of this rubber (boots and the valve cover gasket) was quite hard - not petrified, but very close to being rather brittle.

Also included are a couple of photos of the removed valve cover, and the valvetrain immediately after the cover was removed. Notice it's quite clean in there, as a result of using synthetic motor oil !!

View attachment 15479 View attachment 15481View attachment 15484

Here's a close-up of the brown plastic timing chain top slide rail.

View attachment 15486

Next, I covered the exposed area of the motor with clean rags so that it would be rather protected from airborne pollen, dust and other contaminants.

View attachment 15488

Here are the 16 replacement cam oiler tubes lined up on my work table, ready for replacement. All of the tubes have new, green, MB factory o-rings installed. This is highly advisable to do as a precaution, as older/used sets of oiler tubes will have used rubber o-rings, which can be brittle and/or petrified. I found this exactly to be the case when I removed the old rubber o-rings that came on the oiler tubes. They were quite rigid and fairly brittle.

View attachment 15490 View attachment 15493

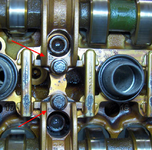

Next step is to begin removing the cam bearing caps, two at a time (one for the intake cam, the other for the exhaust cam. For three of the five towers, you will replace two cam oiler tubes when you remove the pair of bearing caps. DO NOT MIX UP THE CAPS WHEN YOU REMOVE THEM -- KEEP THEM IN THE ORDER AND ASSOCIATED WITH THE CAM THEY CAME OFF OF. The cam bearings are held on by two 11mm bolts, which are re-torqued to 10 Nm when re-installed. For the frontmost and rear-most cam bearing caps, you will only replace ONE tube each. The front-most tube also requires replacement of the plastic slide rail assembly, which will be shown a bit later.

View attachment 15494 View attachment 15496 View attachment 15498 View attachment 15501

Here is a detailed comparison of the plastic vs. metal oiler tubes. Notice that my stock plastic tubes also came from the factory with green o-rings.

View attachment 15502 View attachment 15504 View attachment 15506 View attachment 15509

Here are a few views of installing the new oiler tubes into place .... fitting them and pressing them down with a "click"

View attachment 15510 View attachment 15512 View attachment 15518

After fitting the tube(s) in place, it's time to replace that pair of cam bearing caps. Because I'm rather anal, I cleaned off the bearing surface with a rag, and then added a small dollop of assembly lube that I'd initially used on my M117 rebuild several years back, for exactly the same purpose -- to provide some initial lubrication at startup, until proper oil pressure can be built up and the oil circulates properly through the valvetrain.

View attachment 15514 View attachment 15520 View attachment 15517