Thanks @sheward! I sold our prefacelift w210 E320 many years ago when things were different to get a Prius (HOV lane accessibility!) My wife has never let me forget what a big mistake I made. I am doing penance now.Welcome to the W210 club. I have numerous parts for these cars. The things you mentioned are common issues with 210s.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OWNER jlaa (500E & w210 E320 & w220 S350)

- Thread starter Jlaa

- Start date

They're truly the "Camry" of the Mercedes product line. I have two in the fleet right now but have owned a total of four at any given time. Great cars, very trouble-free, still easy to work on, and don't require anything special or fancy in most cases.

Welcome to the W210 Club!

Dan

Welcome to the W210 Club!

Dan

I think you've done well on this W210, it's a lot of car for the money and plenty of life left in it! IMO, bullet proof engine and transmission combo! And as a bonus, junk yards have many of these for bits and pieces, and God knows MB made enough of them to get used parts if needed!

While I wait for the good stuff to arrive (shocks, brake pads, spark plugs, fuel/air/oil filters, tires, etc..) I decided to replace the HOT TOKYO NIGHTS Alpine radio. The previous owner had a "professional stereo shop" wire in this WIRING MONSTROSITY.

Just look at this HOT MESS ---- KILL IT WITH

---- KILL IT WITH

.

.

Took me a few hours to correct this all ---- the cage was the most frustrating part of the install. Sounds good.

Just look at this HOT MESS

Took me a few hours to correct this all ---- the cage was the most frustrating part of the install. Sounds good.

I see you are enjoying your Porsche packaged leading edge hood foam!Is that the PORSCHE badged version of that Conti radio?

So with the Continental, do you retain factory steering wheel buttons without the need for an adapter?I see you are enjoying your Porsche packaged leading edge hood foam!

maw

The Conti has a provision for steering wheel buttons but I believe this provision is more rudimentary (SWRC - resistive values) and not compatible with facelift 210s and CANBUS. So … my two buttons on the steering wheel …. Vol up/dn are useless now …… unless I figure some converter out…So with the Continental, do you retain factory steering wheel buttons without the need for an adapter?

maw

Last edited:

Visual proof that your typical "professional stereo shop" still hires the cheapest labor they can to chop up your car's wiring in the back room...The previous owner had a "professional stereo shop" wire in this WIRING MONSTROSITY.

Yes! On the topic of accumulating parts for it, I hope you are enjoying the Porsche leading edge hood foam for your w124 for your own hoarding purposes!Yes, you have a whole nother car to begin hoarding parts for ... before more of them follow the W124 and go NLA...... get on it !!

View attachment 178024

I'm fortunate that I replaced my foam center piece and rubber edge pieces with new MB product not that many years ago, when I lived in Texas. Mine is still in excellent condition all around, and I am grateful for this. The Texas climate is very very bad on soft parts, particularly foam and rubber items (think hood center pieces, serpentine belts, and so forth).Yes! On the topic of accumulating parts for it, I hope you are enjoying the Porsche leading edge hood foam for your w124 for your own hoarding purposes!

View attachment 178025 View attachment 178028 View attachment 178027 View attachment 178026

The wonderful Porsche-packaged leading edge hood foam, like the metal 500E tunk badges, front struts, jack-point lower-cladding covers, late front lower control arms, fuel tank level sender, transmission mount, headlight wipers, and many dozens of other parts is a long-term investment into the NLA parts world for the E500E. It is very fortunate that I have a large, shelved and organized basement in which to store these myriad parts in a fully climate-controlled environment.

Your front-end hood foam replacement will, however, never be fully complete without a full investigation into, removal, and replacement of all headlight bucket-area foam on your car. Also DO NOT FORGET the "MOT" valve for the fuel vapor control system -- yours has failed!!!

LOL! You know me better than that … it is new!Also DO NOT FORGET the "MOT" valve for the fuel vapor control system -- yours has failed!!!

Some Progress on the 210. Initial Oil Change. Mobil 1 0W-40 "Euro Car Formula" which meets MB 229.3 specifications. Note my Hazet filter wrench for my Sport Beetle works on the 210 filter housing. Replaced the junk O'Reily's Korean filter with a Hengst filter.

Air Filter replacement - again Hengst. The existing air filter was an MB piece and actually looked to be in spectacular shape.

Fixed the POS sun visors / broken lid with w211 Turkish generic sun visor lids -- had to modify them a little with a dollop of hot melt glue on the switch and the actuating tab to make them light up.

Air Filter replacement - again Hengst. The existing air filter was an MB piece and actually looked to be in spectacular shape.

Fixed the POS sun visors / broken lid with w211 Turkish generic sun visor lids -- had to modify them a little with a dollop of hot melt glue on the switch and the actuating tab to make them light up.

Last edited:

More w210 goodness. @RicardoD and I used my awesome sauce $35 spring compressor tool (being ultra facetious here but also somewhat relieved and surprised) and changed out the front shocks and front spring pads from 2pt to 1pt pads. In our usual style and in keeping with form, we underestimated the amount of time this would take by at least 1/4x. But the good thing is now we know how to use this internal spring-compressor to design now for the w124 (have only used external 2-clamp spring compressors before). Also got to use @RicardoD's awesome 5mmx8mm shock hold-the-rod tool.

I have been working a lot on basic mechanical stuff on this w210, getting it ready for reliable daily operation. I find working on this car super enjoyable for two reasons. First, the car isn't worth very much so the anxiety level is super low going in to jobs that I am unfamiliar with / risk of breakage. Second, while working on this car, I marvel at how similar so many of the mechanical systems are both in layout and design with my 500E, and I am using this w210 as "practice" .... documenting all my jobs before doing the same on the 500E when it needs such service later on down the road.

Replaced front and rear brake pads. For the fronts I used low-dust Akebonos. For the rears I read about the Akebonos not fitting properly, so I used ATE Ceramic pads. No squeal and all have low dust. Interestingly, the front calipers are the single-piston sliding caliper design, whereas the rear are dual-piston.

Replaced rear shocks - Sachs OEM parts. Easy. I probably replaced the originals too soon. The originals still had pressure.

Replaced front and rear brake pads. For the fronts I used low-dust Akebonos. For the rears I read about the Akebonos not fitting properly, so I used ATE Ceramic pads. No squeal and all have low dust. Interestingly, the front calipers are the single-piston sliding caliper design, whereas the rear are dual-piston.

Replaced rear shocks - Sachs OEM parts. Easy. I probably replaced the originals too soon. The originals still had pressure.

Last edited:

Your solution for loosening/tightening the top of the shocks is clever, negating the need for the special tool referenced lately. Either I did not have the ratchet wrench with me or didn't think to use it when recently removing the same nuts tediously, with an open-end wrench.

The two chassis do have many similarities.

The two chassis do have many similarities.

... Brake Fluid Flush --- documented results - fluid went from 1.2% to 0% moisture.

Replaced fuel filter --- first time ever using these fancy ClicR hose clamp pliers. Of course I struggled with the right orientation while fuel poured out of the old fuel filter onto the garage floor. I printed out the instructions and put them in the tool box next to the tool for next time.

I printed out the instructions and put them in the tool box next to the tool for next time.

Replaced fuel filter --- first time ever using these fancy ClicR hose clamp pliers. Of course I struggled with the right orientation while fuel poured out of the old fuel filter onto the garage floor.

Yeah these Mercedes designs are "evolutionary" vs revolutionary, mainly because they almost always start with some Sonderklasse. And of course the 500E is in large part Sonderklasse. So 124, 126, 129, 140, 210, 220 will all be fairly similar when it comes to doing the work of servicing and replacing parts. I think you made a good decision with this car.

maw

maw

Dropped transmission pan for the 722.6 "lifetime fluid" transmission  and flushed out the transmission fluid using 13.5 liters of new fluid. I followed the advice of @LWB250 and @gsxr and another mutual friend and hooked up the line from the trans to the radiator using 1/2" inner diameter clear tubing to flush the trans fluid 2 quarts at a time by starting and running the car ~10 seconds at a time. I measured the ATF fluid with the special 722.6 measurement tool @ 25C and will drive the car more today and re-measure at 80C and top off if necessary.

and flushed out the transmission fluid using 13.5 liters of new fluid. I followed the advice of @LWB250 and @gsxr and another mutual friend and hooked up the line from the trans to the radiator using 1/2" inner diameter clear tubing to flush the trans fluid 2 quarts at a time by starting and running the car ~10 seconds at a time. I measured the ATF fluid with the special 722.6 measurement tool @ 25C and will drive the car more today and re-measure at 80C and top off if necessary.

Last edited:

Thanks. I used a cheaper special tool with the ratchet to hold the strut shaft - https://www.amazon.com/dp/B0C9WDZ7Z9Your solution for loosening/tightening the top of the shocks is clever, negating the need for the special tool referenced lately. Either I did not have the ratchet wrench with me or didn't think to use it when recently removing the same nuts tediously, with an open-end wrench.

The two chassis do have many similarities.

But yeah the flex head ratcheting wrench was GREAT to use instead of an open ended wrench on the nut. The long flex head ratcheting wrench was part of a set a picked up at @jhodg5ck ’s suggestion on this board some years ago!

Last edited:

He's in the PRK, Gerry!NON-chlorinated brake cleaner? Really ?!?

What jlaa is experiencing is the joy of working on a W210, the "Camry" of the Mercedes product line - at least the "standard" models. I dismissed these for years as I never cared for the "moony" looking headlights, but after I got my first one I couldn't stop. There are two in the fleet right now.

Dan

I just came in from cleaning my boat's aluminum stern trim tabs. Heavily encrusted with a couple of (mostly ablated) layers of bottom paint + plenty of barnacles and marine growth.He's in the PRK, Gerry!

Here's an "after" and "before" photo.

20 minutes and some light brushing in muriatic acid took care of all of it. Can you get muriatic / hydrochloric acid in the PRK?

Notice some slight corrosion along the top right (actually the port-side edge when mounted) and along the bottom (starboard-side edge when mounted) of the trim tab on the left. The tab will probably need to be replaced in a few seasons after it corrodes some more. Fortunately they are just sheets of aluminum, rolled at the edges. Not too expensive.

I love the smell of dissolving barnacles in the morning....

@LWB250,He's in the PRK, Gerry!

What jlaa is experiencing is the joy of working on a W210, the "Camry" of the Mercedes product line - at least the "standard" models. I dismissed these for years as I never cared for the "moony" looking headlights, but after I got my first one I couldn't stop. There are two in the fleet right now.

Dan

Dan,

Explain what PRK means to a dumb person who lives here.

I was wiring the car for a rear view mirror monitor from @2phast for a backup cam ... and while waiting for that rear view mirror monitor, I decided "while I am in there" to wire up a control knob that came with my combo DSP/Amplifier that is in my trunk.

The knob is totally programmable in the DSP software settings and I programmed it to:

Anyways - some notes -

The knob is totally programmable in the DSP software settings and I programmed it to:

- Inner Knob - Control the level of the 4x 6.5" midbass drivers in the doors (250 Hz and below)

- Outer Knob - Control the level of the midranges and the tweeters together in the dashboard

- Push on Knob - cycle between DSP presets as indicated by the LED which changes color. I so far have two presets - one which optimizes midbass delay L/R for the deepest bass for the driver of the car, and one which optimizes middbass delay L/R as a compromise-setting for all passengers in the car, no matter where they sit. I could make more presets corresponding to different colors --- but I will have to experiment.

Anyways - some notes -

- The ashtray insert is made of some grey material that does not melt when dremeling it - it devolves into a powder. Hopefully not asbestos.

- The ashtray containment unit that flips in/out definitely melts when dremeling the black plastic behind the door.

- 5mm thin plywood is too hard to make it look primo. Black flat paint helps. If I do a v2, I will use plastic or lexan and paint it flat black.

- The knob requires CAT5 cable with RJ45 connections to connect to the DSP/Amp in the rear. I thought 15 feet would be enough. I was wrong. I have since learned from @jhodg5ck that he always uses 20 foot cable in the E500E when wiring up anything from the trunk. Thank goodness for RJ45 straight-through couplers.

- The stupid white carpet clips work best using a tiny allen key to hammer them in. Don't just bash them in - they will deform.

Attachments

-

IMG_4918.jpeg2.3 MB · Views: 14

IMG_4918.jpeg2.3 MB · Views: 14 -

IMG_4935.jpeg1.8 MB · Views: 11

IMG_4935.jpeg1.8 MB · Views: 11 -

IMG_4945.jpeg1.7 MB · Views: 9

IMG_4945.jpeg1.7 MB · Views: 9 -

IMG_4946.jpeg2.1 MB · Views: 9

IMG_4946.jpeg2.1 MB · Views: 9 -

IMG_4947.jpeg1.6 MB · Views: 9

IMG_4947.jpeg1.6 MB · Views: 9 -

IMG_4912.jpeg1.7 MB · Views: 10

IMG_4912.jpeg1.7 MB · Views: 10 -

IMG_4916.jpeg2.3 MB · Views: 12

IMG_4916.jpeg2.3 MB · Views: 12 -

IMG_4977.jpeg1.8 MB · Views: 21

IMG_4977.jpeg1.8 MB · Views: 21 -

IMG_4985.jpeg2.3 MB · Views: 20

IMG_4985.jpeg2.3 MB · Views: 20 -

IMG_4998.jpeg2.6 MB · Views: 21

IMG_4998.jpeg2.6 MB · Views: 21 -

IMG_5003.jpeg2.4 MB · Views: 19

IMG_5003.jpeg2.4 MB · Views: 19 -

IMG_5004.jpeg2.4 MB · Views: 16

IMG_5004.jpeg2.4 MB · Views: 16

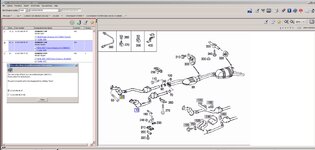

The w210 has been providing reliable daily operation. That said, the catalysts started rattling very loudly, so I did a little bit of digging --- the LHS catalysts were replaced in 2014 20K miles ago, but the RHS catalysts were original. Getting under the car and hitting the catalysts with my fist, I determined indeed it was the RHS catalyst that was rattling. I bought a complete RHS catalyst unit from MB (only $482 for a MB remanufactured unit after returning the core!!) and I lucked out even further as it appears I received a NEW part instead of a remanufactured part. Replacement of the RHS catalyst was straightforward and not even tedious - all the exhaust components came apart in this rust free car without hassle. Note the tool I had to rig up to get to the hard-to-access bolt where the downpipe connects to the exhaust manifold.

Attachments

-

EPC.jpeg632.6 KB · Views: 15

EPC.jpeg632.6 KB · Views: 15 -

IMG_2230.jpeg2.2 MB · Views: 14

IMG_2230.jpeg2.2 MB · Views: 14 -

IMG_2481.jpeg2.2 MB · Views: 12

IMG_2481.jpeg2.2 MB · Views: 12 -

IMG_2489.jpeg2.2 MB · Views: 12

IMG_2489.jpeg2.2 MB · Views: 12 -

IMG_2570.jpeg2.3 MB · Views: 13

IMG_2570.jpeg2.3 MB · Views: 13 -

IMG_2584.jpeg2.4 MB · Views: 12

IMG_2584.jpeg2.4 MB · Views: 12 -

IMG_2615.jpeg2.6 MB · Views: 13

IMG_2615.jpeg2.6 MB · Views: 13 -

IMG_2626.jpeg2.2 MB · Views: 15

IMG_2626.jpeg2.2 MB · Views: 15 -

IMG_2629.jpeg1.5 MB · Views: 15

IMG_2629.jpeg1.5 MB · Views: 15 -

IMG_2640.jpeg2.7 MB · Views: 16

IMG_2640.jpeg2.7 MB · Views: 16 -

IMG_2624.jpeg2.6 MB · Views: 15

IMG_2624.jpeg2.6 MB · Views: 15 -

IMG_2639.jpeg1.3 MB · Views: 15

IMG_2639.jpeg1.3 MB · Views: 15

The w210 interior fittings are not as robust as the w124 interior fittings. In particular, it seems that the plastic tabs that hold down the center console wood become fragile and brittle after repeated center console removal ... especially if the car sat in the hot sun for many years.

When I bought my w210, I observed that the previous owner / previous mechanics had attempted to secure the center console with strong double sided tape after breaking the clips. Of course this looked like azz and it didn't work very well as the double sided tape failed. As well, re-gluing the clips back to the original center console plastic frame that holds the center console wood proved impossible ---- the surface mating area for the clip is just too small to make a robust glue-repair job.

I figured out a way to glue the clip onto a wood block and then glue that block to the plastic frame --- much greater surface area for the glue to work. After several months, my center console wood has stayed in place and I am declaring success. Pictures below:

When I bought my w210, I observed that the previous owner / previous mechanics had attempted to secure the center console with strong double sided tape after breaking the clips. Of course this looked like azz and it didn't work very well as the double sided tape failed. As well, re-gluing the clips back to the original center console plastic frame that holds the center console wood proved impossible ---- the surface mating area for the clip is just too small to make a robust glue-repair job.

I figured out a way to glue the clip onto a wood block and then glue that block to the plastic frame --- much greater surface area for the glue to work. After several months, my center console wood has stayed in place and I am declaring success. Pictures below:

Attachments

Today I learned about a Scuff Gauge.

In October I replaced by worn OE steering wheel with a recovered steering wheel obtained from a forum member. I was careful to align the teeth marks when swapping over the steering wheel from old to new.

However, even though I was careful to do that, my steering wheel ended up being off just a little bit. It wasn't so far off that moving the steering wheel by one tooth would work though - that would have moved the steering wheel too much!

So I went to my favorite alignment place - Custom Alignment in Mountain View. There, they used a SCUFF GAUGE - I did not know this machine existed. I am such a whippersnapper! Apparently this machine was used for 2-wheel alignments a long time ago. The way it works is that you drive over the thing with your front wheels, which will cause those two little metal strips to both rotate and tilt. Somehow, completely mechanically, this then measure the difference in toe between the front wheels.

So the owner of Custom Alignment, Joe :

1) Road tested the car and confirmed that the steering wheel was off just a hair.

2) Drove over the scuff gauge to check toe

3) Adjusted the tie rods by 1/4 turn

4) Road tested the car again

5) Came back to the shop and checked the toe of the scuff gauge again

6) Adjusted the tie rods again by another 1/4 turn (1/2 turn total)

7) Road tested the car --- now the steering wheel was straight) !!

Scuff gauge here:

Apparently this old old machine is a good way to check toe for 2 WHEEL alignments (cannot be used for 4 wheel alignments) and does not require setting up those lasers and reflectors and all that.

In October I replaced by worn OE steering wheel with a recovered steering wheel obtained from a forum member. I was careful to align the teeth marks when swapping over the steering wheel from old to new.

However, even though I was careful to do that, my steering wheel ended up being off just a little bit. It wasn't so far off that moving the steering wheel by one tooth would work though - that would have moved the steering wheel too much!

So I went to my favorite alignment place - Custom Alignment in Mountain View. There, they used a SCUFF GAUGE - I did not know this machine existed. I am such a whippersnapper! Apparently this machine was used for 2-wheel alignments a long time ago. The way it works is that you drive over the thing with your front wheels, which will cause those two little metal strips to both rotate and tilt. Somehow, completely mechanically, this then measure the difference in toe between the front wheels.

So the owner of Custom Alignment, Joe :

1) Road tested the car and confirmed that the steering wheel was off just a hair.

2) Drove over the scuff gauge to check toe

3) Adjusted the tie rods by 1/4 turn

4) Road tested the car again

5) Came back to the shop and checked the toe of the scuff gauge again

6) Adjusted the tie rods again by another 1/4 turn (1/2 turn total)

7) Road tested the car --- now the steering wheel was straight) !!

Scuff gauge here:

Apparently this old old machine is a good way to check toe for 2 WHEEL alignments (cannot be used for 4 wheel alignments) and does not require setting up those lasers and reflectors and all that.

Last edited:

the car ain't bad either.so purty.

The ladies in the family are out of town, so I decided to improve the stereo in my w210.

Firstly, I ripped out these JL Audio speakers ($129) that I installed in the front doors and installed these Rockford Fosgate ($99) speakers. All very inexpensive gear. The JL Audio speakers are absolutely terrible in the doors in this chassis. I have posted a video below where you can hear how terrible the JL Audio speakers are relative to the RF ones. My key learning here was --- always buy speakers from Crutchfield --- they have a 60 day return policy and I ended up getting a credit after returning the JL Audio speakers.

Video 1

Video 2

Then I installed this MB Quart amplifier (4x50watt), replacing this Alpine Amplifier (4x45watt) installed by the previous owner.

The Alpine unit was terrible -- it would clip regularly on bass notes and used a 15 amp fuse (15 amps for 180W/13.5V = 13.3 Amps. Hmmmmm........ Inflated Specs?).

The MB Quart unit was less than $200, about 5x the size of the Alpine, and required a 40 amp (YIKES) fuse. It sounds much better because it doesn't clip.

Of course, my first attempts at installing the amplifier resulted the trunk hinge immediately crashing into it ---

So I had to get creative to save some space so that I could slide the thing forward more (wrestling that OE bracket in/out/in/out/in/out with the telematics module on top is kind of a PITA when I've already mounted 10 pounds worth of electronic gear on it) .....

An entertaining little project. That is all.

PS - I bought this hexagonal crimping tool for this project and it is a very satisfying tool to use to make nice wire ends.

Firstly, I ripped out these JL Audio speakers ($129) that I installed in the front doors and installed these Rockford Fosgate ($99) speakers. All very inexpensive gear. The JL Audio speakers are absolutely terrible in the doors in this chassis. I have posted a video below where you can hear how terrible the JL Audio speakers are relative to the RF ones. My key learning here was --- always buy speakers from Crutchfield --- they have a 60 day return policy and I ended up getting a credit after returning the JL Audio speakers.

Video 1

Video 2

Then I installed this MB Quart amplifier (4x50watt), replacing this Alpine Amplifier (4x45watt) installed by the previous owner.

The Alpine unit was terrible -- it would clip regularly on bass notes and used a 15 amp fuse (15 amps for 180W/13.5V = 13.3 Amps. Hmmmmm........ Inflated Specs?).

The MB Quart unit was less than $200, about 5x the size of the Alpine, and required a 40 amp (YIKES) fuse. It sounds much better because it doesn't clip.

Of course, my first attempts at installing the amplifier resulted the trunk hinge immediately crashing into it ---

So I had to get creative to save some space so that I could slide the thing forward more (wrestling that OE bracket in/out/in/out/in/out with the telematics module on top is kind of a PITA when I've already mounted 10 pounds worth of electronic gear on it) .....

An entertaining little project. That is all.

PS - I bought this hexagonal crimping tool for this project and it is a very satisfying tool to use to make nice wire ends.

Last edited:

I installed a backup cam in my 500E. Finally! Thanks to @2phast for providing the display (rear view mirror)

I've wanted a backup cam on my 500E after getting used to this modern convenience ... but I always detested the aesthetics of cameras which are too bulbous and ungainly or the cams that protrude from the license plate frame like a big wart.

What I really wanted is a backup cam that mounts in place of the rear license plate light like so ---- but no such premade device exists for a w124..... and the sample pictured below is still too bulbous anyways.

The issue with installing an OEM-like discreet backup cam is that there isn't enough room under the trunk handle of the prefacelift cars to mount a cam ---- the cam will always protrude rearward, proud of the handle, which is ugly. It was not until I reverted my 500E's trunklid from USA-spec to Euro-spec by deleting the USA license plate filler that I realized ---- there actually *is* room to mount a cam! The incremental 1/2" of depth gained by this reversion makes it possible!!

![[500Eboard] IMG_2081.jpg [500Eboard] IMG_2081.jpg](https://www.500eboard.co/forums/data/attachments/193/193178-6f8c3883ff760a547b23b833bc746e18.jpg?hash=b4w4g_92Cl)

![[500Eboard] IMG_2089.jpg [500Eboard] IMG_2089.jpg](https://www.500eboard.co/forums/data/attachments/193/193177-57157f9bc18065e9c44f9b11b37a839b.jpg?hash=VxV_m8GAZe)

See the room one has to work with here:

I obtained some spare license plate lights to butcher. I hogged out the middle to fit the body of this camera:

I installed the camera in the light lens and used some JB Weld Steel Stick putty to space-down the camera because the circular camera body WILL NOT fit in the rectangular hole in the trunk lid meant for the light lens.

I added back lighting functionality to the license plate light lens by hot-melt-gluing eight 1.8mm warm white LEDs (to approximate the original incandescent bulb color temp) into the lens. This produced a difference in light dispersion pattern between the left and right side lights (because the left side was still using the original incandescent festoon bulb), so I got another spare license plate light lens and modified that one to take eight warm white LEDs as well. Note that I had to disable the N7 bulb out warning relay to fit LEDs here.

I wired the stuff up thusly .... and noted that I always have to put tape to mark where the plastic panel clips are on the back side of the trunk carpet ---- else I end up blindly pressing them in with my hand and breaking them. :-(

Installation of @2phast 's mirror was straightforward if somewhat tedious for the following reasons. Firstly, the mini-sun-visor, which is not supposed to have been re-installed by the dealer when installing the ceiling phone console (but I kept anyways because I like it) just makes things more fiddly to access. Secondly, the base plastic plate for the ceiling phone console was brittle and cracked along the mounting holes --- so steel washers + more JB Weld Steel Stick to the rescue:

I used a set of Knipex water pump pliers (which I learned about here!) to compress the mirror's spring to insert the mirror mounting tool ... always so fiddly for me. I had to hog out the mounting plate for the review mirror because there's so little space up there and the rear view mirror with display just introduces more wiring bulk. So fiddly. Also I'm not really sure what the best way to grind cast aluminum is. My grinding wheels always get clogged with a thin film of aluminum when I run the wheels quickly. Running the wheels slowly seems to work better, but ugh, so tedious and takes so long. Somebody must know of the proper way (I must be doing it wrong.)

Anyways ---- all done!

I've wanted a backup cam on my 500E after getting used to this modern convenience ... but I always detested the aesthetics of cameras which are too bulbous and ungainly or the cams that protrude from the license plate frame like a big wart.

What I really wanted is a backup cam that mounts in place of the rear license plate light like so ---- but no such premade device exists for a w124..... and the sample pictured below is still too bulbous anyways.

The issue with installing an OEM-like discreet backup cam is that there isn't enough room under the trunk handle of the prefacelift cars to mount a cam ---- the cam will always protrude rearward, proud of the handle, which is ugly. It was not until I reverted my 500E's trunklid from USA-spec to Euro-spec by deleting the USA license plate filler that I realized ---- there actually *is* room to mount a cam! The incremental 1/2" of depth gained by this reversion makes it possible!!

![[500Eboard] IMG_2081.jpg [500Eboard] IMG_2081.jpg](https://www.500eboard.co/forums/data/attachments/193/193178-6f8c3883ff760a547b23b833bc746e18.jpg?hash=b4w4g_92Cl)

![[500Eboard] IMG_2089.jpg [500Eboard] IMG_2089.jpg](https://www.500eboard.co/forums/data/attachments/193/193177-57157f9bc18065e9c44f9b11b37a839b.jpg?hash=VxV_m8GAZe)

See the room one has to work with here:

I obtained some spare license plate lights to butcher. I hogged out the middle to fit the body of this camera:

I installed the camera in the light lens and used some JB Weld Steel Stick putty to space-down the camera because the circular camera body WILL NOT fit in the rectangular hole in the trunk lid meant for the light lens.

I added back lighting functionality to the license plate light lens by hot-melt-gluing eight 1.8mm warm white LEDs (to approximate the original incandescent bulb color temp) into the lens. This produced a difference in light dispersion pattern between the left and right side lights (because the left side was still using the original incandescent festoon bulb), so I got another spare license plate light lens and modified that one to take eight warm white LEDs as well. Note that I had to disable the N7 bulb out warning relay to fit LEDs here.

I wired the stuff up thusly .... and noted that I always have to put tape to mark where the plastic panel clips are on the back side of the trunk carpet ---- else I end up blindly pressing them in with my hand and breaking them. :-(

Installation of @2phast 's mirror was straightforward if somewhat tedious for the following reasons. Firstly, the mini-sun-visor, which is not supposed to have been re-installed by the dealer when installing the ceiling phone console (but I kept anyways because I like it) just makes things more fiddly to access. Secondly, the base plastic plate for the ceiling phone console was brittle and cracked along the mounting holes --- so steel washers + more JB Weld Steel Stick to the rescue:

I used a set of Knipex water pump pliers (which I learned about here!) to compress the mirror's spring to insert the mirror mounting tool ... always so fiddly for me. I had to hog out the mounting plate for the review mirror because there's so little space up there and the rear view mirror with display just introduces more wiring bulk. So fiddly. Also I'm not really sure what the best way to grind cast aluminum is. My grinding wheels always get clogged with a thin film of aluminum when I run the wheels quickly. Running the wheels slowly seems to work better, but ugh, so tedious and takes so long. Somebody must know of the proper way (I must be doing it wrong.)

Anyways ---- all done!

Last edited:

Nice Job! Thanks for being so patient while I finished up your mirror.

For the mounting plate, I have used a round rasp file and also a rotary tool. Much depends upon the grinding bit

These work the best

These do not, they melt the aluminum and the cutting edges get clogged up

For the mounting plate, I have used a round rasp file and also a rotary tool. Much depends upon the grinding bit

These work the best

These do not, they melt the aluminum and the cutting edges get clogged up

Uh, I resemble those remarks! I can recall being trained on one of these when I was in technical school. Even then it was a bit dated, but we had some old-school instructors that could show you stuff that was never documented, like handed down from one generation to another. The guy that did automatic transmissions was a wizard - he knew exactly what every little ball in the valve body did, and what it took to add/remove clutch discs in the clucthes to get better shifts...Today I learned about a Scuff Gauge.

In October I replaced by worn OE steering wheel with a recovered steering wheel obtained from a forum member. I was careful to align the teeth marks when swapping over the steering wheel from old to new.

View attachment 192806 View attachment 192807

However, even though I was careful to do that, my steering wheel ended up being off just a little bit. It wasn't so far off that moving the steering wheel by one tooth would work though - that would have moved the steering wheel too much!

So I went to my favorite alignment place - Custom Alignment in Mountain View. There, they used a SCUFF GAUGE - I did not know this machine existed. I am such a whippersnapper! Apparently this machine was used for 2-wheel alignments a long time ago. The way it works is that you drive over the thing with your front wheels, which will cause those two little metal strips to both rotate and tilt. Somehow, completely mechanically, this then measure the difference in toe between the front wheels.

So the owner of Custom Alignment, Joe :

1) Road tested the car and confirmed that the steering wheel was off just a hair.

2) Drove over the scuff gauge to check toe

3) Adjusted the tie rods by 1/4 turn

4) Road tested the car again

5) Came back to the shop and checked the toe of the scuff gauge again

6) Adjusted the tie rods again by another 1/4 turn (1/2 turn total)

7) Road tested the car --- now the steering wheel was straight) !!

Scuff gauge here:

View attachment 192808 View attachment 192809

Apparently this old old machine is a good way to check toe for 2 WHEEL alignments (cannot be used for 4 wheel alignments) and does not require setting up those lasers and reflectors and all that.

View attachment 192810 View attachment 192811

Old technology is a great thing, and often amazingly simple! What we really need is to make sure the knowledge on how to properly use it is recorded and/or handed down.

Dan

Last edited:

I know right? If I ever move / build a new house, I'm gonna try and install one of these scrub gauges into my garage!Uh, I resemble those remarks! I can recall being trained on one of these when I was in technical school. Even then it was a bit dated, but we had some old-school instructors that could show you stuff that was never documented, like handed down from one generation to another. The guy that did automatic transmissions was a wizard - he knew exactly what every little ball in the valve body did, and what it took to add/remove clutch discs in the clucthes to get better shifts...

Old technollogy is a great thing, and often amazingly simple! What we really need is to make sure the knowledge on how to properly use it is recorded and/or handed down.

Dan

Well, I now have an officially licensed car-driving-teenager in the family. When I was 16, I and all my friends rushed as fast as possible to get a driver's license. However, these days, I have realized that many teenagers have no interest whatsoever in driving --- and doubly so for teenagers that grow up in dense urban areas. I am fortunate that my teenager desires to drive (even though my kid is not a gearhead...)

Well, my kid's car went kaput a week or two ago. See the below video. Look at that water pump pulley wobble and listen to that clanking!!!! @jhodg5ck advised me that "this is about the worst I have ever seen!!" .... and I don't think that was a compliment. . Note that this water pump was original to my 2002 E320 with 63K miles on it. It sure seems like a short-lifespan for this thing!

. Note that this water pump was original to my 2002 E320 with 63K miles on it. It sure seems like a short-lifespan for this thing!

Here is the play in the water pump bearing with the belt and pulley removed. @LWB250 and @gsxr advised to me to change it immediately.

I ordered a HEPU water pump, LITENS tensioner, INA idler pulley, WAHLER thermostat, and GATES serpentine belt from RM European. Much to my chagrin, after waiting all week for the my order to arrive from Pompano Beach, FL, to California, I received my order on Friday afternoon only to discover that the HEPU pump was broken.... no doubt due to poor packaging.

RM European Customer Service closes at 1pm Mountain Time on a Friday so .... my plans for replacing the water pump this weekend were dashed. My local independent to the rescue --- (Junipero Serra Porsche / MB) --- I bought a LASO water pump that they had on the shelf at 4PM on Friday afternoon -

I drained out 8.25 qts of coolant (service records show it was last replaced by the previous owner @ 52K miles in 2017). My 2021 pandemic purchases of Zerex G05 and power-ratchet (which I have never really used) came in handy here. The water pump has 18 bolts and the klunky but value-priced Ryobi power ratchet saved me a ton of time.

Note the play in the bearings / impeller shaft of the OE pump ---- it was TERRIBLE!!!

Having the WIS / EPC in a virtual machine ---- an esoteric tool that I would have never been able to obtain and learn to use had it not been for all the wonderful advice on this board ---- was invaluable in looking up bolt torque specifications.

I carefully put everything back together and tapped two holes on the new pump housing for a bracket. These water pumps come with two gaskets - a rubber seal and a flat metal gasket - you must use one or the other, depending on what came with your car. My car came with the flat metal gasket.

I only made one mistake which wasted an hour when I had to uninstall and re-install the new water pump:

Well, now I have a properly functioning water pump without any leaks and a new a smooth idler pulley and tensioner!!

Well, my kid's car went kaput a week or two ago. See the below video. Look at that water pump pulley wobble and listen to that clanking!!!! @jhodg5ck advised me that "this is about the worst I have ever seen!!" .... and I don't think that was a compliment.

Here is the play in the water pump bearing with the belt and pulley removed. @LWB250 and @gsxr advised to me to change it immediately.

I ordered a HEPU water pump, LITENS tensioner, INA idler pulley, WAHLER thermostat, and GATES serpentine belt from RM European. Much to my chagrin, after waiting all week for the my order to arrive from Pompano Beach, FL, to California, I received my order on Friday afternoon only to discover that the HEPU pump was broken.... no doubt due to poor packaging.

RM European Customer Service closes at 1pm Mountain Time on a Friday so .... my plans for replacing the water pump this weekend were dashed. My local independent to the rescue --- (Junipero Serra Porsche / MB) --- I bought a LASO water pump that they had on the shelf at 4PM on Friday afternoon -

I drained out 8.25 qts of coolant (service records show it was last replaced by the previous owner @ 52K miles in 2017). My 2021 pandemic purchases of Zerex G05 and power-ratchet (which I have never really used) came in handy here. The water pump has 18 bolts and the klunky but value-priced Ryobi power ratchet saved me a ton of time.

Note the play in the bearings / impeller shaft of the OE pump ---- it was TERRIBLE!!!

Having the WIS / EPC in a virtual machine ---- an esoteric tool that I would have never been able to obtain and learn to use had it not been for all the wonderful advice on this board ---- was invaluable in looking up bolt torque specifications.

I carefully put everything back together and tapped two holes on the new pump housing for a bracket. These water pumps come with two gaskets - a rubber seal and a flat metal gasket - you must use one or the other, depending on what came with your car. My car came with the flat metal gasket.

I only made one mistake which wasted an hour when I had to uninstall and re-install the new water pump:

Well, now I have a properly functioning water pump without any leaks and a new a smooth idler pulley and tensioner!!

Last edited:

Similar threads

- Replies

- 0

- Views

- 66

- Replies

- 74

- Views

- 7,547