The dreaded Mercedes

Biodegraded harness rebuilding DIY.

This particular process would be applicable for R129 1995 specifically, that uses lower harness part number 1295402630 (though, earlier years and M119 fitted W124 cars are not all that different when it comes to these harnesses)

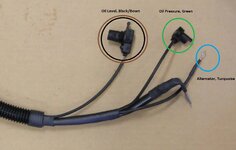

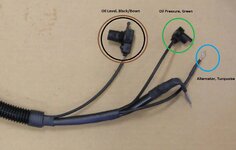

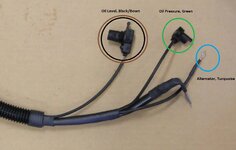

Everyone usually describes replacement of these lower harnesses as pain in the ass, as many pieces need to be moved out of the way (heat shields, starter, very tight quarter, etc) and that turns into hours. After reviewing multiple threads, photos and diagrams of this wiring - technically, there are 2 harnesses in one. Take a close look at these pictures (from Kurth, a well known place that offers these updated harnesses for MB cars)

Affected harness (note the folded part)

Now attached to the heavy gauge wire with loom and mounting points to make it a "full harness"

The main power section (not affected by deterioration) , and one with 4-5 wires (depending on the model) that has affected wiring, and still, not all is affected:

The white/purple wire (heavier gauge), that's going to the starter seems to be unaffected in all the harnesses that I've seen, perhaps a different supplier with a different material used for this one...

The only way to get to the starter wire terminal, is to remove the starter, and that's quite bit of work. And since this starter wire has no damage - no need for starter removal of the the rest of the headaches! The harness can be easily separated.

Observing and practicing all the safety practices is a must (including safety glasses, battery disconnection etc)

Parts needed:

0185454328 harness plug (male) (discontinued) - reuse if possible or 2nd hand

0115458528

0115458528 oil pressure plug (available) - order new (or reuse if in good condition)

0145450728

0145450728 oil level plug (discontinued) - reuse if possible or 2nd hand

18awg quility wire, 6' for each wire

Wire loom

Shrink wrap

Ring Terminal (alternator wire)

Factory harness plug on 1995 SL500

These are the affected 3 wires:

BROWN BLACK -Engine Oil Level PIN 3

GREEN - Oil Pressure PIN 2

TURQUOISE - Alternator PIN 4

New wires, as factory, high temperature, 18awg... These braze nicely

Factory pins de-soldered, and new wires soldered in (fancy non-conductive wooden jig)

Test fitted into the factory harness plug (I'm using a spare harness plug to build the harness)

Test fitting the loom and trim to size

Now that all the wires are soldered to the smaller pins at the harness plug, next step do the following:

De-solder a larger pin from the white/purple (starter wire, still attached to the car)

Pull it out of the factory loom (routing the factory loom -see the path of it's routing)

Continued downwards (ignore the dust/dirt and dirt under the plastic cover)

Continues forward and down under the intake tube

And finally terminates with the plugs under the Oil Filter/Alternator area (pretty it is not!!!)

Disconnect, remove and clip-off the oil level, oil pressure and alternator terminal at the lower end of original harness, remove and disgard these 3 damaged wires.

Slide on 3 individual wire looms and 3 individual pieces of shrink wrap onto the distal end of the new wires

Solder on the oil pressure and oil level pin bushings back to the new wires at the distal end. along with the alternator connector

Finished connectors, sleeved and shrink wrapped.

Slide about 16" of a small diameter loom onto the starter wire, slide it all the way down to the distal end, as far as it can go, it's the only chance you will have. I've also use the shrink wrap to secure the sleeve loom onto the starter wire. This area is where the factory harness mates with the heavy gauge wire

Insert the proximal end starter wire into the distal portion of the new wire loom and feed it upwards toward the harness plug while routing the new harness downards path.

Solder the starter pin terminal back up, insert back into the harness plug, tidy up the plug and connectors (shrink wrap etc) close it up and this part is done...

Reconnect the lower parts of the newly made harness (oil pressure, oil level and alternator)

Tidy up the wiring

Reattach the harness into receptacle

Reconnect the battery

Enjoy years of worry free lower harness with out any Side effects of biodegradable materials (at least on this portion of the car)

While other W124 and R129 cars may have slight variation of these lower harnesses, for example, early R129 cars had extra wire in the harness, Pin #5, that utilized the 2 pin oil pressure unit plug such as this one

I believe all can be re-wired in the manner as above... Hope you can find it useful for your MB cars with affected lower harnesses.

Regards,

D

P.S. This is what my garbage harness and pieces looked like

One wire actually melted!!!

I would have enjoyed that drive as well.

Besides, I really do enjoy this type of work, table top, music on, no hurry... I like pretty wires!

Besides, I really do enjoy this type of work, table top, music on, no hurry... I like pretty wires!