I am building this car for member viking1, it is nearing completion and I thought it was good time for a build thread.

Quick run down :

Car:

Rust and accident free 1994 S124 E320 Green on Tan - 225,000 happy gasoline powered miles

Sold at Beverly hills MB and came with original window sticker

Motor:

-1999 OM606.962 - Horsepower goal is 600+RWHP 700+TQ and 3.5+Bar of boost

-DieselMeken 8mm pump

-Precision PT6466 Dual Ceramic Ball Bearing Turbo V-band in/outlets

-Precision PW46 Wastegate 21psi springs for "low" boost

-Full 3" stainless exhaust

-AEM Methanol Injection with 2.5 Gallon tank

-Bosch 044 fuel pump

-Aeromotive adjustable FPR set to 15psi

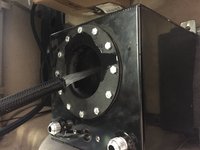

-Water to Air intercooler with dual heat exchangers mounted on either side of the bumper

-5 Gallon tank with Bosch Cobra water pump

-Air Conditioning!

Transmssion:

-BMW ZF320 5 speed from E36 M3 (Known for taking lots of abuse in turbo E36s)

-Diesel pump UK ZF adapter

-DPUK Clutch and flywheel

-E34 M5 765 Sachs Pressure plate and Disc

-Custom E46 Shift arm and Selector rod

-Custom Cross brace

-W201/124 Manual Pedal box

-M104 Driveshaft lengthened 45mm

-WaveTrac LSD 2.65

-Rebuilt Axles

Suspension:

-Bilstein HD front struts with new mounts

-All new steering components

-Lorinser lowering springs

-New wheel bearings front and rear

-New front control arms

-New Front and Rear Subframe bushings

-New Diff Mounts

-All new rear links

-LCA Bushings inner/outer

-SLS delete with rear air shocks

Brakes:

-R129 Silver Arrow Brembos Front and Rear (Thanks GSXR!)

-Goodridge stainless brake lines

-ATE Type 200 Fluid

Wheels:

-18x8 - 18x9 / ET31 - 35 E55 Monoblocks, freshly refinished in silver with machined lips

-Potenza RE-71Rs

Body:

-Full AMG body kit, the car came with genuine side skirts and rear bumper already installed. Need to source a matching front bumper

I am organizing all the pictures now, I will post them in a little while

Quick run down :

Car:

Rust and accident free 1994 S124 E320 Green on Tan - 225,000 happy gasoline powered miles

Sold at Beverly hills MB and came with original window sticker

Motor:

-1999 OM606.962 - Horsepower goal is 600+RWHP 700+TQ and 3.5+Bar of boost

-DieselMeken 8mm pump

-Precision PT6466 Dual Ceramic Ball Bearing Turbo V-band in/outlets

-Precision PW46 Wastegate 21psi springs for "low" boost

-Full 3" stainless exhaust

-AEM Methanol Injection with 2.5 Gallon tank

-Bosch 044 fuel pump

-Aeromotive adjustable FPR set to 15psi

-Water to Air intercooler with dual heat exchangers mounted on either side of the bumper

-5 Gallon tank with Bosch Cobra water pump

-Air Conditioning!

Transmssion:

-BMW ZF320 5 speed from E36 M3 (Known for taking lots of abuse in turbo E36s)

-Diesel pump UK ZF adapter

-DPUK Clutch and flywheel

-E34 M5 765 Sachs Pressure plate and Disc

-Custom E46 Shift arm and Selector rod

-Custom Cross brace

-W201/124 Manual Pedal box

-M104 Driveshaft lengthened 45mm

-WaveTrac LSD 2.65

-Rebuilt Axles

Suspension:

-Bilstein HD front struts with new mounts

-All new steering components

-Lorinser lowering springs

-New wheel bearings front and rear

-New front control arms

-New Front and Rear Subframe bushings

-New Diff Mounts

-All new rear links

-LCA Bushings inner/outer

-SLS delete with rear air shocks

Brakes:

-R129 Silver Arrow Brembos Front and Rear (Thanks GSXR!)

-Goodridge stainless brake lines

-ATE Type 200 Fluid

Wheels:

-18x8 - 18x9 / ET31 - 35 E55 Monoblocks, freshly refinished in silver with machined lips

-Potenza RE-71Rs

Body:

-Full AMG body kit, the car came with genuine side skirts and rear bumper already installed. Need to source a matching front bumper

I am organizing all the pictures now, I will post them in a little while

Last edited: