Welding ongoing and will take weeks still.

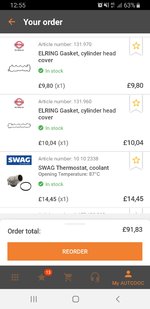

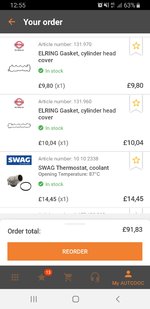

Did a full service on its transmission including a fluid flush at the weekend. And ordered valve cover gaskets + a thermostat as a smaĺl "break" from the weldathon

Whilst awaiting that stuff to come from Germany I will order up new oil breather hoses from the dealer too.

I spotted an oil drip from the rear crank seal, that will have to wait until I get my 2 post lift put up.

Did a full service on its transmission including a fluid flush at the weekend. And ordered valve cover gaskets + a thermostat as a smaĺl "break" from the weldathon

Whilst awaiting that stuff to come from Germany I will order up new oil breather hoses from the dealer too.

I spotted an oil drip from the rear crank seal, that will have to wait until I get my 2 post lift put up.

BUT when do you sleep? Don't you have an Architectural business to deal with also?

BUT when do you sleep? Don't you have an Architectural business to deal with also?

The cardboard is perfect for making templates for new steel. Trace the edges (what's left of them) with your thumb and it stays on the cardboard. Then cut to size and sharpie around it onto the new steel. I want this area replaced as one galvanised sheetmetal strip

The cardboard is perfect for making templates for new steel. Trace the edges (what's left of them) with your thumb and it stays on the cardboard. Then cut to size and sharpie around it onto the new steel. I want this area replaced as one galvanised sheetmetal strip