The dish soap should work significantly better. Car soap is formulated weak to avoid stripping wax.

You are right! See below. This post is titled -

MURPHY'S LAW STRIKES AGAIN!

Back in February,

@RicardoD helped me replace the clutch slave cylinder in my sport beetle. I have one of the "993" variety and

@RicardoD has one of the "964" variety and he looked at his clutch slave cylinder and access didn't look to bad, do we decided to both buy the same aftermarket clutch slave cylinder (bigger piston, more fluid displacement, more pedal travel for same amount of clutch actuation = more easily modulated clutch and less effort).

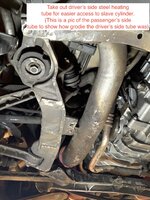

Anyways we started with my car in Feb. BAD IDEA. My "993" has a shit-ton more suspension links in the back than Ricardo's "964" variety and access is a frolicking pain in the butt 'cos the thing is buried near the centerline of the car up at the top of the transmission and no one's arms are long enough to reach through all those gotttdam suspension links so the only way to access it was to go from underneath, BLIND, and totally by feel. Look for the red thing.

So in my infinite, excuse, completely finite wisdom, I decided I never wanted to touch that damn thing again, and since bleeding the clutch requires touching it, I decided to extend the bleeder screw with a bleeder -> 3AN adapter and then run a 3 foot 3AN line to the engine bay in the back with a bleeder screw so that bleeding the clutch would be easy --- in the engine bay.

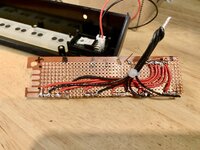

I ordered an aluminum bleeder -> 3AN adapter (cuz the clutch slave cylinder is aluminum) and I figured I was being clever, I mean idiotic, by avoiding dissimilar metal corrosion. I figured it would take me two hours max to take off the bleeder screw, screw in the aluminum adapter, then screw in the 3AN line and route it to the engine bay. You can see where this is going right?

I first screwed in the adapter with the slave installed in the car. Then I screwed in the 3AN line to the adapter.

OF COURSE HOLY MOTHER OF %$@%$@%!!!! What happened was that I was doing everything blind. I should have used two wrenches when screwing in the 3AN line - one to hold the aluminum adapter and one to crank down the 3AN line. But I didn't do that. I just cranked the 3AN line hex, which also rotated the adapter, which is aluminum and therefore soft, and it sheared off with a pice LEFT INSIDE THE SLAVE CYLINDER!!! ARGH.

So I had to uninstall and reinstall the clutch slave cylinder again. Myself. @RicardoD graciously texted me throughout the whole ordeal offering encouragement. The one thing I vowed never to do - to touch that damn slave again - I had to do .... because I had embarked on a project to avoid touching it!!!!!

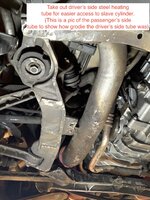

Anyways, I learned some tricks, like taking out the steel heater hose which gave more access. I was lucky and the adapter remnant came out easily:

And look here

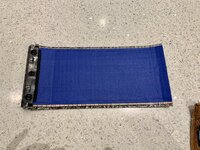

@sheward and

@a777fan and

@Duh_Vinci ---- DISH soap works GREEEAAAATTT in the ultrasonic cleaner ! It took off almost all the cosmoline!

And DISH SOAP cleaned up my engine under tray mounting bracket!

So now I tossed the alu adapter and used a steel one instead, dissimilar metal corrosion be damned:

And I reinstalled in back in the car --- leaning from Ricardo's texts all the way --- this time cocking the slave cylinder on the threaded mounting studs so that it wouldn't shoot off in space with the internal spring (all blind):

Of COURSE the 3AN line I ordered was too short:

Which means now I need to order an additional 21" of line (NFW I am removing that slave cylinder again to install a longer line) and install the extension with a male 3AN to male 3AN adapter. Sigh.....

.gif)