Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest !

Welcome to the 500Eboard forum.

Since its founding in late 2008, 500Eboard has become the leading resource on the Internet for all things related to the Mercedes-Benz 500E and E500. In recent years, we have also expanded to include the 400E and E420 models, which are directly related to the 500E/E500.

We invite you to browse and take advantage of the information and resources here on the site. If you find helpful information, please register for full membership, and you'll find even more resources available. Feel free to ask questions, and make liberal use of the "Search" function to find answers.

We hope you will become an active contributor to the community!

Sincerely,

500Eboard Management

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

group buy - Wavetrac differentials for w124

- Thread starter Jackasic

- Start date

A

amin206

Guest

Hello I saw wavetrack lsd for w124 is still available in their site. but I have a question is that the same product as you guys bought it in 2014-15 or is it different?

Should be identical. I'm not aware of any changes but you could always contact Wavetrac directly and ask.Hello I saw wavetrack lsd for w124 is still available in their site. but I have a question is that the same product as you guys bought it in 2014-15 or is it different?

Same thing. No changes.Should be identical. I'm not aware of any changes but you could always contact Wavetrac directly and ask.

Sent from my SM-G960U using Tapatalk

Hello I saw wavetrack lsd for w124 is still available in their site. but I have a question is that the same product as you guys bought it in 2014-15 or is it different?

Its the same unit nothing was changed...

Leistung is a Stocking dealer for this specific diff so if you need one contact them directly. www.leistungautohaus.com

I thought it was a limited production run for the group buy and shortly thereafter, but I guess I was mistaken. Interesting and good to know.

Some questions:

1. How did everyone like the wavetrac LSD in the end? Noisy/clunky, or not?

2. Who are these blokes on ebay advertising $1245?

3. Does this thing come with some instructions for installation?

4. Did anyone ever find the appropriate c-clips for the stock axle stubs?

Thanks

1) There is zero noise or clunkiness from the WaveTrac, Quaife, or factory clutch-type LSD. But unless you track your car, it's questionable if you'd ever notice the difference with normal street driving.

2) No idea about the eBay vendors.

3) Zero instructions. Either pay a rear-end shop that knows how to do Mercedes diffs (this is critical!), or DIY it with the FSM (advanced job, tool fabrication required).

4) Yes, I thought at least with the group buy the clips were included, but WaveTrac probably cheaped out and didn't put them in the box. The part number should be buried in a thread somewhere.

2) No idea about the eBay vendors.

3) Zero instructions. Either pay a rear-end shop that knows how to do Mercedes diffs (this is critical!), or DIY it with the FSM (advanced job, tool fabrication required).

4) Yes, I thought at least with the group buy the clips were included, but WaveTrac probably cheaped out and didn't put them in the box. The part number should be buried in a thread somewhere.

Only thing I will add/counter to dave is I think a LSD is an Awesome mod...esp on the street!

Couple our Early ASR w/ a proper LSD and it no longer becomes a total kill joy...esp if you're trying to get the jump/make a quick u-turn or anything else that involves turning and the gas pedal @ more then 1/2 way.

I also find the cars more stable when driving spiritedly up/around/through the twisties...and should things get a little over the top ASR actually cuts in @ moments that make Sense once both wheels are being driven... If things Really get out of hand, I find how the car responds to my inputs to correct far more natural w/ an LSD. Open diff's do strange things when going sideways...@ least strange in my mind.

Anywho, i've said it before but quantifying an LSD in an 036 is one of the harder things to do verbally but hop back and forth from one w/ LSD vs not, go for a run down your fav road and you'll be Sold...

Couple our Early ASR w/ a proper LSD and it no longer becomes a total kill joy...esp if you're trying to get the jump/make a quick u-turn or anything else that involves turning and the gas pedal @ more then 1/2 way.

I also find the cars more stable when driving spiritedly up/around/through the twisties...and should things get a little over the top ASR actually cuts in @ moments that make Sense once both wheels are being driven... If things Really get out of hand, I find how the car responds to my inputs to correct far more natural w/ an LSD. Open diff's do strange things when going sideways...@ least strange in my mind.

Anywho, i've said it before but quantifying an LSD in an 036 is one of the harder things to do verbally but hop back and forth from one w/ LSD vs not, go for a run down your fav road and you'll be Sold...

Only thing I will add/counter to dave is I think a LSD is an Awesome mod...esp on the street!

Couple our Early ASR w/ a proper LSD and it no longer becomes a total kill joy...esp if you're trying to get the jump/make a quick u-turn or anything else that involves turning and the gas pedal @ more then 1/2 way.

I also find the cars more stable when driving spiritedly up/around/through the twisties...and should things get a little over the top ASR actually cuts in @ moments that make Sense once both wheels are being driven... If things Really get out of hand, I find how the car responds to my inputs to correct far more natural w/ an LSD. Open diff's do strange things when going sideways...@ least strange in my mind.

Anywho, i've said it before but quantifying an LSD in an 036 is one of the harder things to do verbally but hop back and forth from one w/ LSD vs not, go for a run down your fav road and you'll be Sold...

I dont really drive that hard, but the e420 with a 2.82 and no asr is a bit squirrely, so I am pretty sure an 87 td 606 with compound turbos and 4-500 hp and gobs of torque with a 2.65 and no asr is going to require both rear tires to put the power down, esp on corner exits and launching.

ECS tuning has the diff for 1245.50. I keep seeing higher numbers but not sure why.

I would be happy to pay someone to do the job, but I am not sure what it is worth. Maybe $200. Any more and I would rather futz around with it myself and order some bearings and seals.

Thanks for the input. Any vids of the install process? I think my 8 year old and I can enjoy the build together.

If you have a car WITHOUT ASR... by all means, you need a limited-slip diff! It's a YUGE difference compared to a peg-leg open diff.

Labor to install is somewhere in the range of 6-10 hours total, including pulling the diff out of the car, taking it apart, installing the LSD, checking backlash & preload, praying it doesn't need to have the shims adjusted, then re-installing everything. This is advanced DIY and other than a few photos on my website, the main reference is the FSM (from the 126 chassis) which walks you through the process. If you don't have access to precision dial gauges and have the ability fabricate some tools as needed, you'll be far better off paying someone that has done this before. If you screw it up, it's an expensive lesson.

Labor to install is somewhere in the range of 6-10 hours total, including pulling the diff out of the car, taking it apart, installing the LSD, checking backlash & preload, praying it doesn't need to have the shims adjusted, then re-installing everything. This is advanced DIY and other than a few photos on my website, the main reference is the FSM (from the 126 chassis) which walks you through the process. If you don't have access to precision dial gauges and have the ability fabricate some tools as needed, you'll be far better off paying someone that has done this before. If you screw it up, it's an expensive lesson.

If you have a car WITHOUT ASR... by all means, you need a limited-slip diff! It's a YUGE difference compared to a peg-leg open diff.

Labor to install is somewhere in the range of 6-10 hours total, including pulling the diff out of the car, taking it apart, installing the LSD, checking backlash & preload, praying it doesn't need to have the shims adjusted, then re-installing everything. This is advanced DIY and other than a few photos on my website, the main reference is the FSM (from the 126 chassis) which walks you through the process. If you don't have access to precision dial gauges and have the ability fabricate some tools as needed, you'll be far better off paying someone that has done this before. If you screw it up, it's an expensive lesson.

It's 14+ hours per MB to R&R and Build the diff.

I'd split that time about in 1/2 for each part of the job.

jono

It's been years since I've done this, but IIRC pulling the pumpkin out of the car wasn't too bad, 1-2 hours if all the fasteners cooperate... another 1-2 for installation. Strip any bolt heads or break stuff, and uh-oh.It's 14+ hours per MB to R&R and Build the diff.

I'd split that time about in 1/2 for each part of the job.

The LSD install, I never timed it, but it can be a LOT of hours. I'd estimate it takes me 10 or so but I'm not rushing it. I figured a pro shop that has done many could possibly manage it in 4-6 hours, that's just for a carrier R&R, and checking preload/backlash. Add hours more if it needs re-shimming: have to take it apart AGAIN, put it all together again, measure again, if still not right you take it apart and re-shim... repeat as needed. Not fun. This is assuming you do not touch the pinion at all. If the pinion is removed to replace the bearings, add another pile of hours. I leave the pinion alone if it's smooth and quiet.

All of which is why I like to upgrade a spare diff on the bench so I can take my time, then just spend the couple hours swapping the pumpkin in the car... no downtime.

atg, if you are anywhere near Hotlanta, I'd call Jono and see what he can work out for an installed WaveTrac... I believe he's an authorized dealer, and is one of the few places in the USA that I'd trust to do it right.

I am replacing the diff with a 210mm. So the diff is already on my bench. I didnt want to do this now actually, but then I lost a half shaft so it needed a new subframe anyway as the diff got ripped halfway out.

So I got a 500e subframe from Matt last weekend on my way to san diego. I already had the 500sl diff. Half shafts went to cvjreman in Denver on Monday for an overhaul. 420 driveline arrived yesterday. Urethane bushings from Poland are all on my bench. Four bolt flange for the transmission output is en route. All the links are pretty much new and what isnt will get new bushings anyway. Need some diff mounts I guess. And some guibos. And a center support and bearing.

I hate to be a cheapskate as it is clear Matt knows what he is doing, but dropping 2k on a diff rebuild wasn't really something had planned for right now. I keep thinking a diff rebuild should be cheaper than that, even with 1250 plus bearings and seals in parts. $700 in labor when the diff is already out? Seems steep.

So I got a 500e subframe from Matt last weekend on my way to san diego. I already had the 500sl diff. Half shafts went to cvjreman in Denver on Monday for an overhaul. 420 driveline arrived yesterday. Urethane bushings from Poland are all on my bench. Four bolt flange for the transmission output is en route. All the links are pretty much new and what isnt will get new bushings anyway. Need some diff mounts I guess. And some guibos. And a center support and bearing.

I hate to be a cheapskate as it is clear Matt knows what he is doing, but dropping 2k on a diff rebuild wasn't really something had planned for right now. I keep thinking a diff rebuild should be cheaper than that, even with 1250 plus bearings and seals in parts. $700 in labor when the diff is already out? Seems steep.

WaveTrac should supply the spring clips needs to retain the axle stub shafts, but I guess we'll find out when we receive them.

You'll need to buy other stuff separately... I'd replace the differential side oil seals, O-rings for the side bearing carriers, and the ASR sensor O-rings too. Oh, you'll need to buy the bearings too... part numbers shown here, click the "bearing" pics. We'll need to have Gerry create one of his signature "HOW TO" threads for the LSD install.

NOTE: There is an EPC error on the ASR sensor O-rings... EPC only shows the thick O-ring for plastic ASR sensors, it should also show the thin O-ring for metal sensors. Every 036 that I've touched has the metal sensors, which requires O-ring 014-997-97-48 (not shown in EPC).

Anyone have part numbers for the bearings?

I think 700$ is a good price. Given the tools and experience you need to do the job professionally. I had to change the shims on my diff during the Wavetrac install. Luckily I had several shims in my parts bin. Quite some are NLA for now but a specialized shop might have some in the parts bin too.

If you DIY the job, you'll see why they charge what they do. $700 isn't cheap for an LSD install, but it's not outrageous either. If the $700 includes fiddling with the pinion too, just pay the man.I hate to be a cheapskate as it is clear Matt knows what he is doing, but dropping 2k on a diff rebuild wasn't really something had planned for right now. I keep thinking a diff rebuild should be cheaper than that, even with 1250 plus bearings and seals in parts. $700 in labor when the diff is already out? Seems steep.

Keep in mind the WaveTrac has no wear parts, has a lifetime warranty, and you could remove+resell for about what you'd have in it.

Of the 13 shim thicknesses originally available, only 6 were still available a few years ago; the rest are NLA. I don't know current status. MB expects you to use a thicker shim and have it machined down as needed. To get the numbers exactly in spec, you often need increments of 0.05mm. Meaning that (for example) a 1.70 may be too much, 1.60 is too little, and 1.65 would be just right. And MB only has 1.60 and 1.80 available, so you need to buy a 1.80 (or use that 1.70 you just tried) and machine it. Fun stuff.I think 700$ is a good price. Given the tools and experience you need to do the job professionally. I had to change the shims on my diff during the Wavetrac install. Luckily I had several shims in my parts bin. Quite some are NLA for now but a specialized shop might have some in the parts bin too.

If you DIY the job, you'll see why they charge what they do. $700 isn't cheap for an LSD install, but it's not outrageous either. If the $700 includes fiddling with the pinion too, just pay the man.

I kind of get it, but I would think any decent shop is going to have or be able to fabricate any type of shim required. I am happy to pay for good work but in reality I don't have any way to get the diff to Leistung this week and I am trying to get this job done. Metric, Sun Valley etc are all within about 20 min of my house. I'm guessing there is a rear end shop closer to me that can handle this.

Just make sure the rear-end shop has done Mercedes diffs, and is familiar with the shims. If not... don't let them touch it.I kind of get it, but I would think any decent shop is going to have or be able to fabricate any type of shim required. I am happy to pay for good work but in reality I don't have any way to get the diff to Leistung this week and I am trying to get this job done. Metric, Sun Valley etc are all within about 20 min of my house. I'm guessing there is a rear end shop closer to me that can handle this.

Remember the WaveTrac needs special fluid, as mentioned previously, the Motul Gear 300 is recommended. And do not use the OE diff cover sealant (blue Hylomar), use the MB black goo (or Right Stuff).

Yah you may be right about that. If I had thought about it I would have dropped it there when I scooped up the subframe from him.If I were you I would find the time to get it to Matt. Don’t mess around trying to save a $.

Think “Pay me now or pay me later”

Sent from my SM-G955U using Tapatalk

I already have the fsm so will just follow that.Is there a write up on this install anywhere? Or a parts list?

Sent from my SM-G955U using Tapatalk

Sent from my SM-G955U using Tapatalk

Too small for what? The axle stub shaft splines are the same regardless of differential type. They are single-use, the clip will become distorted during installation/removal and should be replaced each time.

Ok so clearly there is no way to get the stock clips back on with the diff in the case. So I'm guessing these other clips go down the bore and lock into the diff with spring pressure. That all seems doable.

But how do you remove the clips to get the axle stubs back out if you need to?

So far this job is not that big a deal. But I am not messing with the pinion.

You pull real hard.Ok so clearly there is no way to get the stock clips back on with the diff in the case. So I'm guessing these other clips go down the bore and lock into the diff with spring pressure. That all seems doable.

But how do you remove the clips to get the axle stubs back out if you need to?

So far this job is not that big a deal. But I am not messing with the pinion.

Make sure your mesh pattern is Correct ..just because your not touching the pinion doesn't mean your diff hasn't opened up and require re-shimming.

Jono

Sent from my SM-G960U using Tapatalk

I figured as much.You pull real hard.

Make sure your mesh pattern is Correct ..just because your not touching the pinion doesn't mean your diff hasn't opened up and require re-shimming.

Jono

Sent from my SM-G960U using Tapatalk

Backlash is ok with original shims. Still need to check the case deflection and contact pattern. Thanks for the tips.

Karl

Sent from my SM-G955U using Tapatalk

Whaaa....? Which gear ratios is it "opened up to" and which ratios require spacers? I hope they are just adding spacers for 3.27 / 3.69 applications. There should be a completely different unit (with different dimensions) for 2.24/2.47 gears. I really hope they didn't screw it up.

Again: Whaa...? There is no need to touch the pinion or crush sleeve to install the WaveTrac! You don't need to remove the pinion unless changing gear ratios, which is always a bad idea - buy a diff with the ratio you want. The link below is an article from Stu Ritter which explains in detail why it's a Very Bad Idea to mess with the pinion, unless you have all the special tools, and word on the playground is that only a handful of shops in the USA have the tools to do this properly:

http://www.w124performance.com/docs/mb/other/differential_info_Stu.txt

IMO, the bigger nuisance for WaveTrac (or Quaife, or factory LSD) installation is that many of the shim thicknesses are NLA, and if you want to get the bearing preload and gear backlash exactly in spec, you may need to buy thicker shims and have them ground down in 0.05mm increments as needed. And even when you have a proper shim assortment, it's a lot of trial & error assembly. I've built something like 6 or 7 of these so I'm quite familiar with the process. It's not difficult, just time consuming.

Side note: This may not be widely known, but I was the one who worked with WaveTrac back in 2013 to have them develop the diff for the 500E application. They wanted to build one that required custom machining of the factory axle stub flanges, and I had to convince them this was a terrible idea and nobody would buy one if they did that. It was a lot of time and effort, I had to send them multiple diffs for R&D, all at my cost out of pocket. I was supposed to get a free WaveTrac diff for my efforts and I never did get that, which still pisses me off. (They made a pile of money off selling dozens of these, not even a thank you?) As a bonus, they never returned the flanges I send them for R&D so now I also have a 500E diff collecting dust that is useless without the flanges. I like their product but I am not impressed with their customer service. </rant>

Bumping this thread since I have bought one of these from Member Doolar. My 500E has had some play in the diff since I got it about 4 years ago. There is a bump under the car when going from D to R and it is within the diff as far as I recall. Hence it will need overhauling.

I thought when I tackle that job I may as well have an LSD installed. It will be mid or late next year until I get to this - I guess if I can find a diff building specialist near me then the best thing to do is bring them my diff and the Wavetrac. Before I do that - is there anything internally to the diff I might inspect first?

I have had similar slop in a C36 W202 Diff before and it was one of the pins inside the differential which was bad. If my 500E has a problem like that again then the Wavetrac will replace those components anyway.

Dave- are you saying above that you have DIY'd the installation of these Wavetrac LSD's without special MB equipment? It is something I would rather do myself if I can. My 500E diff is not making noise or anything at all - "just" that there is noticeable play in the gears or internal components.

Could I for example, clean everything - inspect for obvious wear or damage and if good fit the Wavetrac and check the feel of the diff and maybe use engineer's blue to see how the gears are meshing? General questions I know. I am just fearful that any Diff shop I find here will not be familiar with these old MB Diffs and may just "throw it together" whereby I would take considerably more care doing the job if I thought it was within the realms of an experienced DIYr

So, I took a few days off and went back home. Finally got time to assemble the 2.65 diff with all new bearings and the wavetrac lsd. I was lucky to have some spare adjustment spacers for the side covers, many sizes not available anymore! Got the pinion gear pre load, pinion to Crown wheel play and housing pre loading nicely dialed in after changing spacers a few times. Filled it with Castrol 75W140. If I have time during the upcoming weekend I even might install it.

Was there any special tooling you needed Rouven to check the

pinion gear pre load, pinion to Crown wheel play and housing pre loading?

If the existing diff is OK - no gear whine on/off throttle, no excess play or wear, etc... it is DIY'able. However you will need dial gauges / micrometers, and you may need to fabricate some tools, as seen in my photos here.Dave- are you saying above that you have DIY'd the installation of these Wavetrac LSD's without special MB equipment? It is something I would rather do myself if I can. My 500E diff is not making noise or anything at all - "just" that there is noticeable play in the gears or internal components.

I measured the backlash and bearing preload of the old/existing setup before taking it apart, then used that as a guide when installing the new diff. The bearing preload was generally low (near zero) on the old stuff, and I usually had to dink with different shims to get things back into factory spec. Backlash was almost always within spec on the old/worn diff.Could I for example, clean everything - inspect for obvious wear or damage and if good fit the Wavetrac and check the feel of the diff and maybe use engineer's blue to see how the gears are meshing?

Adjusting either backlash OR preload is a pain as many shims are NLA and you have to buy thicker ones, and machine them thinner as required. That said... if the measurements aren't way out of spec, you can probably get away with using the existing shims and it should end up awfully close to spec without all the headaches of going ±0.05mm on either side.

I would not touch the pinion at all, for any reason, unless something is wrong with it. The one exception would be if the pinion shaft seal is leaking. A special tool is specified for this job (to measure 'friction moment') but many techs simply mark the position of the nut before & after (this also means you *must* re-use the old nut, and old flange). Crown wheel play (backlash) and housing pre-load can be measured using home-made tools and a micrometer/dial-gauge.Was there any special tooling you needed Rouven to check the pinion gear pre load, pinion to Crown wheel play and housing pre loading?

Click here for a writeup by Stu Ritter about diff work, note that he's generally discussing a full teardown & rebuild, and/or changing a gearset which requires pinion R&R. Setting pinion depth sounds like a total nightmare and I wouldn't attempt it without the proper tools (which I don't have, and most shops don't either).

@gsxr thanks for the usual great information and details. Definitely food for thought and I understand now what you mean by the pinion nut etc.

I guess what I will start with when I get to this job is determining first of all what has the slop /play in my 500E's Diff and see what else might need renewed.

I guess what I will start with when I get to this job is determining first of all what has the slop /play in my 500E's Diff and see what else might need renewed.

Some questions:

1. How did everyone like the wavetrac LSD in the end? Noisy/clunky, or not?

2. Who are these blokes on ebay advertising $1245?

3. Does this thing come with some instructions for installation?

4. Did anyone ever find the appropriate c-clips for the stock axle stubs?

Thanks

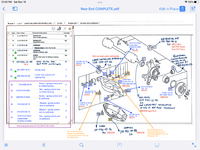

@atg @gsxr - are these the c-clips that are needed when installimg a wavetrac diff? (The 203 part number)1) There is zero noise or clunkiness from the WaveTrac, Quaife, or factory clutch-type LSD. But unless you track your car, it's questionable if you'd ever notice the difference with normal street driving.

2) No idea about the eBay vendors.

3) Zero instructions. Either pay a rear-end shop that knows how to do Mercedes diffs (this is critical!), or DIY it with the FSM (advanced job, tool fabrication required).

4) Yes, I thought at least with the group buy the clips were included, but WaveTrac probably cheaped out and didn't put them in the box. The part number should be buried in a thread somewhere.

when I am looking at this picture, what am I looking at?

The reason I ask is because I am not sure if the OE (not the 203 part) c-clip is on this diagram (and that I have ordered the wrong part) or if I am looking at the wrong diagram. I want to make sure I have all the parts requires to swap the diff. Thanks.

@Jlaa there should be 2 of those clips in the OE packaging in the Wavetrac box somewhere. Maybe wiggled between the foam packing.Yup, you want the 203- clip for Quaife or Wavetrac.

The 115- clip is for factory 124/129 differentials.

Oh I see it now! Thank you!@Jlaa there should be 2 of those clips in the OE packaging in the Wavetrac box somewhere. Maybe wiggled between the foam packing.

Nice that Wavetrac included those. I worked with them to develop this unit, and had to convince them that yes, a snap ring was needed to make the stock axle flanges work. I think they wanted to require people to modify the axle flanges and I said "no way". Ended up sending them the clips and part number, along with some other stuff...

Thank you for setting wavetrac straight! I bet you didn’t think that people would be thanking you for this work nearly 10 years later!Nice that Wavetrac included those. I worked with them to develop this unit, and had to convince them that yes, a snap ring was needed to make the stock axle flanges work. I think they wanted to require people to modify the axle flanges and I said "no way". Ended up sending them the clips and part number, along with some other stuff...

Last edited:

Yes. You would need a spacer and longer bolts to attempt to fit 3.27 gears.I'm looking at upgrading my 300E differential to a 210mm unit from a W140, I already have a Wavetrac fitted to my 560SEC. Question is the W140 unit I have located from a S320 has a 3.27:1 ratio. Is the Wavetrac definitely only suitable for 2.65 to 3.06?

Make sure the W140 diff has the ABS sensor required for your 300E. 94/95-up 140's eliminated the sensor at the diff.

Give Jeff @ Byrd's Garage in the UK a call. Quaife has Bunch more options for ring gear back spacing and the exchange rate is Handy for us current;y!@Many thanks, I wasn’t aware of the ABS sensor change, will keep looking for a more suitable differential.

Similar threads

- Replies

- 13

- Views

- 1,742

- Replies

- 22

- Views

- 6,447

- Replies

- 11

- Views

- 2,000

- Replies

- 69

- Views

- 7,246

Who has viewed this thread (Total: 1) View details

Who has watched this thread (Total: 4) View details

Similar threads

- Replies

- 13

- Views

- 1,742

- Replies

- 183

- Views

- 23,255