Re: M104 / W124 Top-End Rebuild

Here's a post with some random notes and musings I've been thinking about for the past couple of days, as my top-end rebuild progresses. I hope y'all find these of interest, and some relevance to the E500E world.

First, the first box from my third (and next to last) parts order rolled in today. Inside the box were my 28 new cam bearing cap bolts, which (per your thought Michael) are exactly the same as the ones that are currently holding the bearing caps onto the head. I also received 11 of the 14 new head bolts -- I assume the other three will be in the second package, arriving from MB's Carol Stream, IL warehouse tomorrow (Tuesday). As I'm now on Christmas holiday for the rest of the year, I've plenty of time to enjoy working on the car out in the shop.

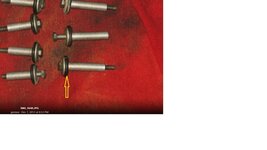

One of the parts that came in today's box were the copper exhaust manifold nuts. These nuts are a "one-use" nut, meaning that they are discarded upon removal from the car, and new ones are supposed to be used. The interesting thing about them is that they are shaped slightly differently than most other nuts. Take a look at the photos below. Can you see what is different from most ordinary nuts?

View attachment 21509 View attachment 21510

I've received a couple of PMs and comments here from folks who are interested how I keep records of what I do. Well, besides the photographic record, I maintain a log in an ordinary student composition notebook (the ones with the black and white speckled cover) with all steps performed, as I do them. I also record the following things, on separate pages and in the margins:

- time worked during each day's session

- description of any parts broken/cracked during removal, that require replacement

- number of cups of coffee and 60oz sodas consumed during working hours

- comprehensive list of part numbers & descriptions for parts orders

- any handy notes, such as torque values, part quantities, thread pitches, etc. that I may find handy

- diagrams of subsystems that are needed for re-assembly (i.e. vacuum line or wire bundle routings & placement)

Here are a couple of photos of some of my notes from this project:

View attachment 21511 View attachment 21512

Next, one of the things I'll be doing is replacing the timing chain. I had ordered (via AHAZ) an IWIS chain (MB OEM) and I opened it up to see what kind of master link it had -- there are a couple of different kinds. Indeed, it is the "plate" type and I am going to need to borrow my mechanic's chain riveter/press to install the new chain - basically to crimp down the end links to keep the center and edge plates in the proper place on the chain. It's a fairly easy operation, but the tool is very specialized, and last I checked around $800 from MB. It will be basically an overnight use for me -- my mechanic doesn't use it all that often.

View attachment 21513 View attachment 21514 View attachment 21515

And here are a few photos of me on my continuing clean-up of the pistons. This is a view of cylinders #3 (right) and #4 (left) at the beginning of (#3) and before (#4) the piston crown cleanup process. Basically this is a lot of elbow grease and patience, and takes about 30 minutes to clean 80-90% of the baked-on carbon from the piston. Most of this time you are hunched over the fender or radiator, or in my case sitting on top of the ABS pump (it's nice and flat, though not very comfortable) and leaning over the now exposed block.

View attachment 21516 View attachment 21517 View attachment 21518

And lastly..... an investigation of the wiring in the cable for the ORIGINAL ETA that was in the car. This ETA, as you can see from the first photo below, is dated November of 1994, so was the original unit. It was working just fine when removed, but it was only a matter of time before it would have shorted out and caused problems. And after opening it up ... I am doubly glad that I did this job now. Now remember, this ETA had ONLY been removed and had been fairly gently handled since removal, spending most of its time sitting on the garage floor.

You can see what the situation was, when I slit open the wiring cable. The photos pretty much speak for themselves. To say I was living on borrowed time, is an understatement.

View attachment 21519 View attachment 21520 View attachment 21521 View attachment 21522 View attachment 21523

This ETA biodegradeable wiring situation shown above (both wiring in the external cable bundle and inside the housing) is also a common problem with the E500E, given enough time and mileage.

Just wanted you guys to see this.

Cheers,

Gerry

Super fun following along and reading the questions/comments from others here too