The engine head is still in the machine shop. Went there and spent two hours watching the master machinist at work, who was fixing a Porsche head, four-cylinder with 8 valves. Saw my own engine head all cleaned up with valves all removed. They scheduled the repair to my engine head next Monday, hopefully finishing it by Tuesday.

This master machinist learned the trade from his father in South Africa and is so skillful. He explained the work he was doing to me. I know the theories but to see how the theories are implemented practically is quite an experience. He already ground the valves. The intake valves were provided by the custemer, made by AE, while the exhaust valves are Porsche original. They make a differnece. He explained to me the roundness of the AE valves is not as true, resulting the sealing problem with the valve seat.

I then watched him rim the valve guide and then hone them for proper fit and surface finish. I got to feel the clearance of a valve and its guide. He explained that he typically goes for 0.001". There will be thermal expansions of the valve, so it cannot be too tight.

After that, using a mandrel as guide, he machined the valve seats. Then he tested the sealing with vacuum. The exhaust side is perfect, but the intake is quite there. As he turns the valve, the vacuum reading changes, indicating not round or straight fitting. He then lapped the valve and seat individually for each intake valve, spinning a spindle by hand with some lapping compound. After a few tries, all valves seal properly.

He also showed me a VW head with 20 valves (5 valves per cylinder). Next, after he installed the valve springs, he would machine the valve end so that they would be at the same height because the valve seats are not necessarily the same when he machined them. He explained that he could only take out a little bit each time or it might chatter, ruining surface finish. I asked him what if he cuts too deep, he then showed me the valve seat inserts which can be inserted with shrink fit.

It is all about concentricity.

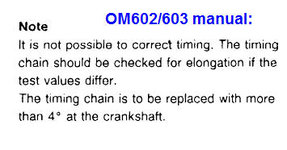

I came away with a full confidence that he would me the engine head so good and my engine will be like new again. He actually measure the clearance of my valve guide and valve stem, and noted it is about 0.0015", a bit on the upper side but should be fine. He went to the computer but he could not find the spec for E320, 1994. He found C280 and diesel. The cost to fix the valve guide is another big ticket item. I should not need it.

Should be able to get the head back next week and then the assembly process will start.

A final thought is that skillful person like this master machinist is a dying trade. This person is still quite young, probably in his early or mid 40s. He is the only one working on the valve jobs at this machine shop and this machine shop is the only one in the triangle area of North Carolina. He told me that no young people are interested because they go for bigger money, mostly computer and internet related stuff (bitcoin, for example), where the big money is. Sad but true.

jftu105