Re: M104 / W124 Top-End Rebuild

To all -- my sincere apologies about the too-frequent updates over the past few days. You are all probably thinking I am having a bad case of diarrhea of the keyboard or something.... so apologize in advance for this.

Well, about 1.5 hours out in the shop tonight and I achieved the major remaining milestone required, before installation of the cylinder head: the replacement of the timing chain. It only took about 45 minutes for the actual replacement job and that was taking my time and great care. I was very lucky to have the special Assemnacher tool that is used to press the timing chain link together and then crimp it into place, borrowed from my friend Larry Gheorge, who owns GR Auto Care (a Mercedes/BMW repair shop) in nearby Spring, Texas. Larry is always a great source of friendly MB related banter and advice, and we loan each other tools and equipment with some regularity. GR is where G-Man recently took his 500E to have the transmission rebuilt, among other work.

Anyhoo .... I had my wife help me but unfortunately as our hands were full (literally) I was unable to get photos of the actual chain replacement. BUT, there is plenty of before and after photos and I'll fill in the chain replacement process verbally so that you get a good idea for how it went.

First off, before getting started on the chain replacement exercise, I double-checked and cleaned out the channel in the top edge of the lower timing cover, where the seal will fit for the top part of the cover. I was lucky that previous mechanics had not mucked this all up with loads of RTV sealant, so I didn't have to clean out much. Just cleaned up the oil with a rag, and some brake cleaner spray to make things purdy. You can see a bit of RTV or other sealant on the underside of the driver's side timing chain rail (which I'm not going to bother to clean up) but otherwise , no muss, no fuss with the sealing area itself. It's ready for me to struggle to get the top timing cover on when the time is right.

The next order of business was to get the exposed top of the engine covered up, in advance of the deluge of very fine pieces of ground timing chain link and pins that would soon be spraying forth from up above, as I ground down the pins to separate the chain. I put several layers of rags down to keep things well protected -- particularly the "chain box" area where the timing chain goes down to the crank sprocket.

Then it was time to actually "press on" with the job of the timing chain replacement. The first step was to use my Dremel Moto-Tool, with a grinder bit attached, to grind down the pins that held the link on the chain. As I was replacing the chain with a new one, it didn't matter WHERE on the chain that I selected -- location was not important. Here you can see me as I get started with the Dremel.

Here are some "action" shots as I ground down the ends of the pins.

After I got things ground down, there was just a little space in between the links to work in the end of a jeweler's screwdriver, which began to pull the link cap off the end of the pin. It gave me a bit more room so that I could stick a larger, flat-blade screwdriver in there to pop it off. Here you can see the results of that. See how much the end link itself got ground down? Probably a bit more than I should have, but since it was going to be discarded, I wasn't too concerned about it .... until a few minutes later.....

Here's a view of the timing chain, with the end link removed.

Then it was time to get out the NEW Iwis timing chain, and get it ready for the forthcoming operation.

I cleaned the metal shavings from the ground pins and end link off of the chain, as best I could with a well-oiled shop rag, making 5-6 passes to be extra sure that as much of the shavings were gone as possible. The reason being because that old chain would be descending down into the engine in just a few minutes, and I wanted to minimize metal shavings down in the chain box area.

Now comes the break in the photos, so I'll have to describe the next few operations verbally, and unfortunately not illustrate them photographically.

The next step was to separate the ends of the old timing chain. I had my wife help me, and she held the two ends of the chain that appeared as I removed the end link with the attached pins, that I had ground off the other side of. She held the ends of the chain so that the chain wouldn't fall downward into the chain box, and also so that the chain would stay wrapped around the crankshaft chain sprocket.

Then I attached the ends of the new chain to the ends of the old chain, using the old and new links with pins, and end caps. I used a pair of Knipex channel-lock pliers to press the end caps onto the pins enough so that they would stay put for their journey over the crankshaft sprocket, but not tight enough so that they would be difficult to remove after the new chain was rolled into the motor.

I had my wife hold the newly combined, double-length chain up with two hands, while I rolled the old chain and part of the new chain into the engine, around the crankshaft sprocket, and out the other side. Once I rolled the link up far enough, I had her continue to hold the chain while I popped off the end links and removed the old chain.

The next step was to assemble the newly supplied Iwis master link (with pins), center link plate and end link, and join the ends of the new chain together. I used the special Assenmacher press tool to do this, after I press-fitted the end cap onto the pins, thereby relieving my wife of the need to hold the chain up further. At this point, I re-attached the bungie cord I'd been using to hold up the old chain, and she was done. Total time for her in the garage was about 20 minutes or so.

Here is a photo of the old chain, just after removal from the engine after the new chain was rolled in.

Here's the new end-cap, press-fitted onto the pins of the new chain's master link. The next step is to press the end-cap into place with the tool.

And here's the special Assenmacher chain-press and crimping tool in use, moving the end cap into its final position on the pins. This tool costs over $800 from MB !! To operate the press, you simply turn the pin clockwise, using a 13mm wrench, to move the end cap onto the pins.

And here's the new Iwis end cap, pressed into place on the pins. It's the darker black link in the chain.

After the end cap was in place, it was time to crimp the two pins, to keep that cap in place on the chain. The beauty of the factory (and Assenmacher) chain tool is that it easily converts to a crimping tool, just by switching the "bit" in the tool by 90 degrees. So here I am, switching the tool from "press" mode to "crimper" mode.

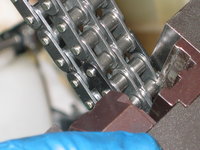

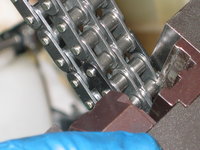

And here I am, using the tool to individually crimp each pin. Notice the bevel that is applied in the crimping process, to the sides of each pin. This is the same as the other pins on the Iwis chain's other links. I provide a few close-up photos for your reference.

And, a couple of photos of the finished new chain. Mission accomplished !! The timing chain installation was a major milestone in the rehabilitation of the top end of this motor !!

Cheers,

Gerry

...twelve? Were they all 5.0L...is that why there are less 036's on the road?

...twelve? Were they all 5.0L...is that why there are less 036's on the road?

).

).