10/26/2024

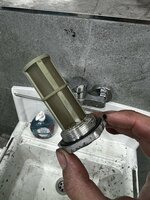

A stud welder is just the best thing ever. This would have been a lot more work without it… and i also found some more rust under the rear seats. This will be taken care of when the rear subframe is out too.

View attachment 203143View attachment 203144View attachment 203145View attachment 203146

Great thread and fantastic work there well done

Welding is a tedious task on any car but you will get it all done and know your car inside out at that point! And know also that it will outlive the others on the road which likely have the same rust but no one knows where to look or want to take the time to fix it properly.

If you can get dinitrol wax underseal I highly recommend a product like that as an additional protection. A cavity wax for inside any welded areas like cills etc and a black wax coating on the outside over the new primer / stone chip. It will add very good protection and ensure your hard work stays 100% for decades to come.

Do you have any details on the stud welder above please? Is that an attachment for a welder or a special machine? I normally mig or Tig weld my own studs on so that would be a time saver for the mountain of welding I still have ahead of me on several 124s and 140s.