Hey there,

i figured it's time to share my journey of V8 W124 ownership now as well. I joined the 500Eboard a few months ago and i've really been enjoying all the content on here. The amount of valuable information on here is really mind boggling. A big thank you to everyone being kind enough to share their knowledge.

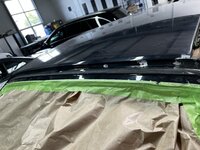

The car is a 1993 E420 with the code 953 Sportline option, which i bought in November 2023. It's got about 342.000km (212.500mi) on the clock and has very terribly been resprayed in the past (more detailed pictures of the paint job later):

50 shades of silver... I also don't have any better photos of it in assembled condition - the car is currently in the paint/body shop of my gf's family, but more on that later.

I'll throw the option list (wrong one) that lastvin gave me in here:

FIN WDB1240341C043422

Model 400 E

Engine 119975 12 013984

Transmission 722366 03 910387

Order Number 0 2 249 02283

Order Location AUGSBURG BRANCH

Approx. Build Date 1993-09

Code Description

So far i have driven the car about 1500km with the only noticeable issue being a clunk in the rear when shifting load. Well, i will be adressing all the technical stuff (engine, chassis, etc.) in the future.

Right now the car is undergoing a looooot of welding and being prepared for a full respray. I started working on that in the beginning of March and have taken a lot of pictures of the work i've been doing. I will try to post everything i have done so far in chronological order.

i figured it's time to share my journey of V8 W124 ownership now as well. I joined the 500Eboard a few months ago and i've really been enjoying all the content on here. The amount of valuable information on here is really mind boggling. A big thank you to everyone being kind enough to share their knowledge.

The car is a 1993 E420 with the code 953 Sportline option, which i bought in November 2023. It's got about 342.000km (212.500mi) on the clock and has very terribly been resprayed in the past (more detailed pictures of the paint job later):

50 shades of silver... I also don't have any better photos of it in assembled condition - the car is currently in the paint/body shop of my gf's family, but more on that later.

I'll throw the option list (wrong one) that lastvin gave me in here:

FIN WDB1240341C043422

Model 400 E

Engine 119975 12 013984

Transmission 722366 03 910387

Order Number 0 2 249 02283

Order Location AUGSBURG BRANCH

Approx. Build Date 1993-09

Code Description

- 240 OUTSIDE TEMPERATURE INDICATOR

- 260 TYPE DESTINATION ON TRUNK LID - ELIMINATION

- 305 DUST FILTER

- 404 MULTI-CONTOUR SEAT, FRONT LEFT

- 412 ELECTRIC SLIDING ROOF WITH TILTING DEVICE

- 471 ACCELERATION SKID CONTROL (ASR)

- 480 SELF-LEVELLING SUSPENSION

- 531 AUTOMATIC ANTENNA

- 551 ANTI-THEFT/ANTI-BREAK-IN WARNING SYSTEM

- 570 FOLDING ARMREST, FRONT

- 580 AIR CONDITIONER

- 620 VEHICLES WITH CATALYST TECHNIQUE

- 682 FIRE EXTINGUISHER

- 751 BECKER RADIO GRAND PRIX 2000 VK RDS

- 859 MODEL UPDATE II

- 864

- 884 TRUNK LID ADDITIONAL LOCKING MECHANISM (HZS)

- 240 outside temperature indicator

- 243 sports seat in front and rear

- 260 elimination of type sign on trunk lid

- 278A leather perforated grey

- 281 steering wheel 390mm and gearshift in leather trim

- 305 dust filter

- 412 electric tilting/sliding roof steel

- 471 acceleration skid control (ASR)

- 538 automatic antenna and front loudspeaker without radio installation

- 580 air condition

- 590 heat-insulating glass all-around with rear window pane laminated glass

- 611 courtesy lamps for front and rear doors

- 620 exhaust emission control

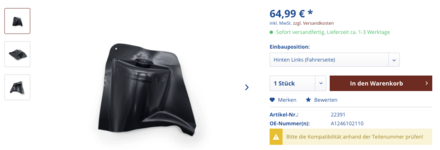

- 653 sport chassis with light alloy rims 8-hole

- 682 fire extinguisher 1.3 kg

- 744U Brillant silver metallic

- 859 MODELLPFLEGE II

- 864 ?

- 873 heated front seats

- 953 Sportline with 8-hole rims

So far i have driven the car about 1500km with the only noticeable issue being a clunk in the rear when shifting load. Well, i will be adressing all the technical stuff (engine, chassis, etc.) in the future.

Right now the car is undergoing a looooot of welding and being prepared for a full respray. I started working on that in the beginning of March and have taken a lot of pictures of the work i've been doing. I will try to post everything i have done so far in chronological order.

Last edited: