Ok, I did a little more research this afternoon and some digging in the car, and I think I now have some answers.

@Jlaa to answer your question about how the Mono Valve and Coolant Pump are 'protected', I took a look at the 124 ETM.

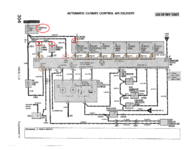

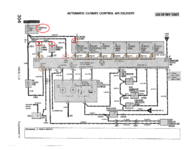

Here is the Power/Ground Schematic for production from 1987 onward.

Note, I have annotated this with brown lines that represent the fact that the Switchover Valve Unit (Controls the Air flappies), the Mono Valve and the Coolant Pump are all grounded through the PBU. This will become clearer in the next figure. But for now

@Jlaa and

@gsxr note that all 4 of these items get their power from Fuse 7. So that is one question down.

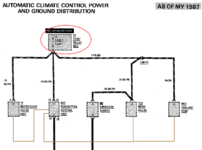

On to the next figure which gives us the pin-out for the PBU. We can use that to determine how all four of these items work together.

I have also annotated this figure to show the power (red) and grounds (brown) of interest. You can see that conveniently (and as noted on the previous figure as well) that the PBU, the Monovalve, the Switchover valve unit and the Coolant Pump all get their power from one source. This makes troubleshooting all the components pretty easy, as you can check the various resistances of ALL of the components right at the X1 and X2 connectors! So thats what I did. I got out my multi-meter and started checking. Here are the results:

Check out that Mono-valve number!!!

I think it's pretty shot. Do you all concur?

I also have questions about the Coolant Pump Number. It seems high. Does anyone know what the spec is?

Side note - I also ohmed out the Aspiration Blower. No need to hunt around under the dash. Referencing Figure 2 above, just disconnect the connector from the Mono valve, find the pin with the black/purple wires, and then check the resistance from there to ground. I got 5.1 ohms, which also seems high. Also looking for confirmation of the spec on that one.

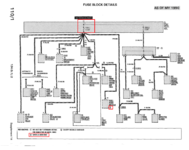

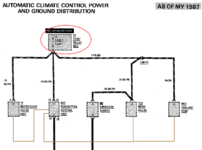

So... the Mono-valve is essentially shorted completely out at this point. All that current with nothing to stand in the way pumping right into the poor little PBU. I assume the blower motor kicking on was simply an artifact of the control module melting/catching on fire. That still doesn't explain why the fuse that controls all of these components did not blow. For that, I did a little more digging and comparing. First.. remember the ETM Power distribution figure? Let me remind you what it said, zooming in:

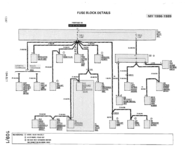

Fuse 7 - 8 Amps. Cool. Lets go over to the fuse box and see what it looks like...

White is 8 amps.... Red is 16... WTF?!

Did I goof up when I installed my non-

metallic aluminum fuse set?!?! Let's check:

NOPE! The car calls for a 16 Amp fuse in this location!!! So... WTF!?!?

My guess is that somewhere along the lines of the W124 lineage, new items kept getting added on to Fuse 7, which required a bump from 8 amps to 16. Did they do all their homework when they made that change? I do not know. All I know is that I have a 16 amp fuse in my fuse box, a broken Mono-Valve and an absolutely BBQ'ed PBU!

Once I have put everything back (new Mono etc), I plan on making Fuse 7 an 8 amper, and see how that goes. Maybe it will be enough, maybe it will immediately blow. If I am forced into a 16 amp fuse in that location, I will certainly be adding a check of the Mono-valve resistance to my annual maintenance tasks.

Anyway, it was an interesting evening, so I wanted to share with you guys. It feels somewhat good to have some certainty behind the cause of all this. Let me know your thoughts and observations. If I were you, I'd go check the resistance of my mono valve ASAP!

Oh... btw looks like i have the 'newer' Monovalve

<--- Car-B-Que

<--- Car-B-Que